Method for simulating vulcanization of all-steel radial tire

A technology of radial tires and vulcanization degree, which is applied to tires, other household appliances, household appliances, etc., can solve the problem of rapid grid division method that does not involve changes in thermal conductivity, specific heat capacity and density of rubber-steel composite materials, and does not involve tire vulcanization system and other problems to achieve the effect of improving the quality of tire products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

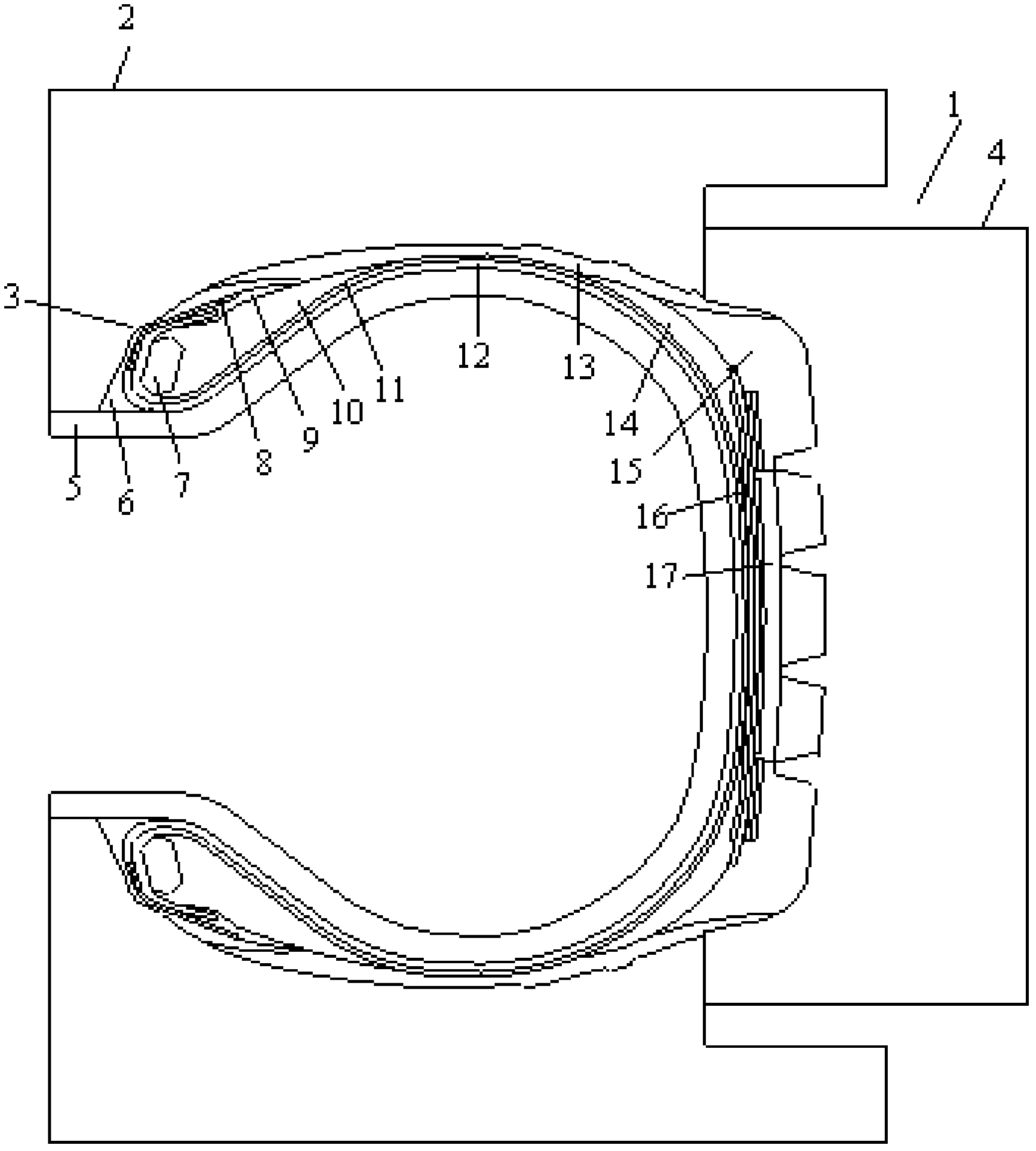

[0017] Such as figure 1 As shown, the simulation state structure of the meridian plane of the tire vulcanization system 1 to be simulated includes a metal mold 2, a tire 3, a metal mold 4 and a water bag 5, and the tire 3 is located between the metal molds 2, 4 and the water bag 5. The tire 3 also includes a wear-resistant layer 6, a bead ring 7, a reinforcing layer 8, a pad rubber 9, an excessive rubber 10, a carcass layer 11, an inner liner 12, a sidewall 13, a shoulder pad rubber 14, a crown 15, a belt Bundle layer 16, crown base rubber 17, this is the known structure of tire 3. Among them, the reinforcement layer 8, the carcass layer 11 and the belt layer 16 are of rubber-steel wire composite material structure, the metal mold 2, metal mold 4, and steel traveler 7 are of metal structure, and the rest are of rubber material structure. During vulcanization, the high-pressure superheated water circulates in the water bag 5, and the water temperature of the superheated water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com