Clamp for assembling one-way clutch

A one-way clutch and fixture technology, which is applied in the direction of manufacturing tools and workpiece clamping devices, can solve the problems of damage to the function of the one-way clutch, complicated assembly operations, etc., and achieve the effect of easy assembly, rapid assembly, and realization of assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

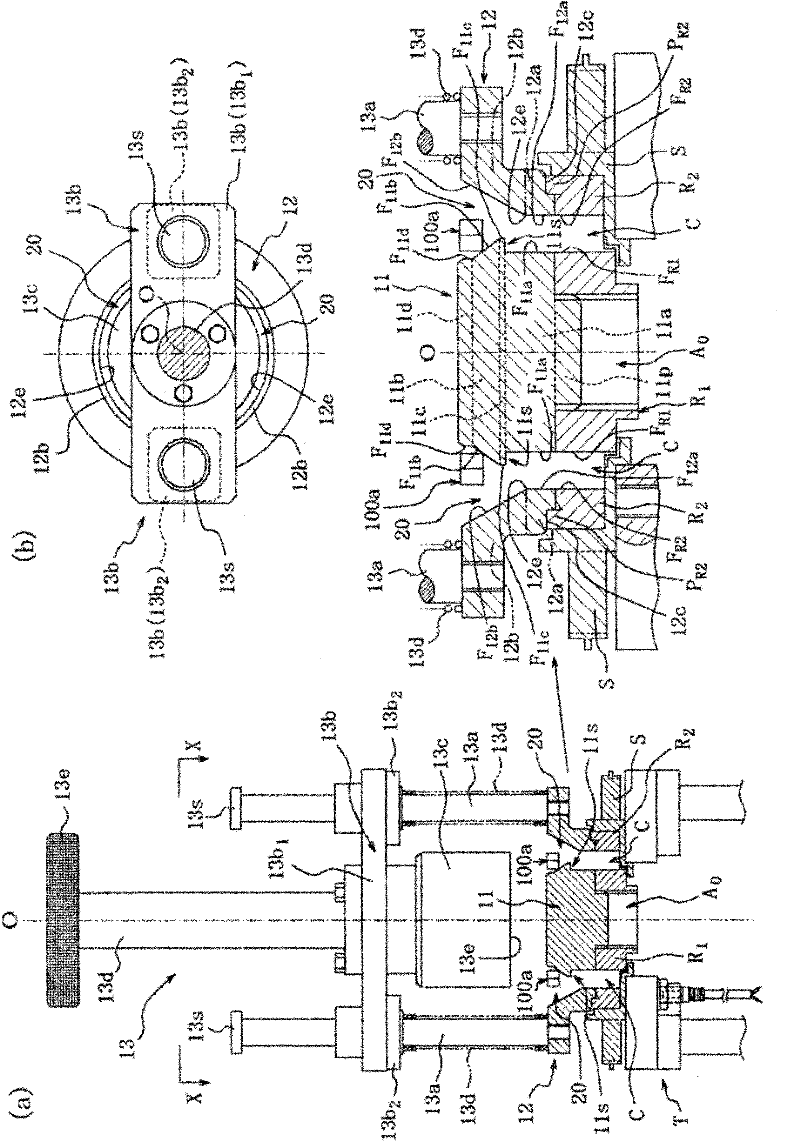

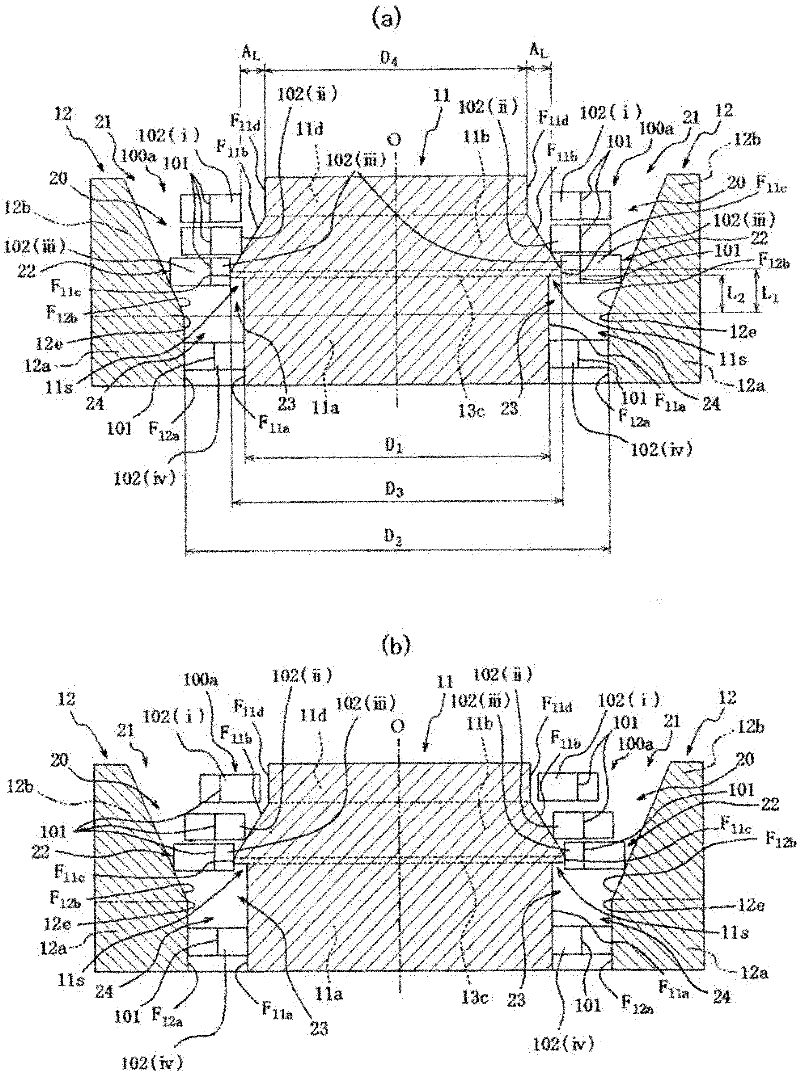

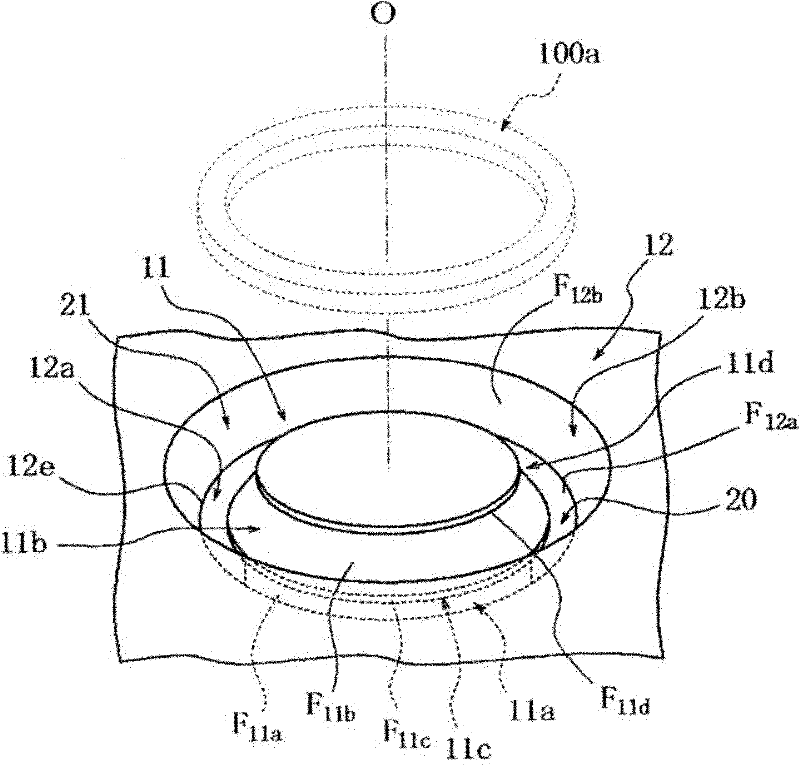

[0059] Hereinafter, one embodiment of the jig for assembling a one-way clutch according to the present invention will be described in detail with reference to the drawings.

[0060] Such as Figure 6 , 7 As shown in the example, the one-way clutch 100 of this embodiment is used for the stator S of the torque converter. Inner ring R 1 The worm gear is spline-fitted via the spline hole formed inside it, and the outer member R 2 is fixed on the stator S. Thus, the one-way clutch 100 connects the drive shaft and the stator S and rotates them integrally until the drive shaft reaches a certain rotation, thereby enhancing the torque converter function and When the rotation speed of the drive shaft reaches a certain value or more, the connection between the drive shaft and the stator S is released to idle the stator S, thereby preventing the torque increase function from being degraded due to the increase in the rotation of the drive shaft.

[0061] In the figure T is assembled on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com