Headbox for a machine for producing a fibrous web

A fibrous material and headbox technology, applied in paper machine, paper machine wet end, textile and paper making, etc., can solve the problems of high cost of distribution tube orifice plate, pressure loss of fibrous material suspension, and headbox operation stability structure Unfavorable compactness and other problems, to achieve the effect of reducing pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

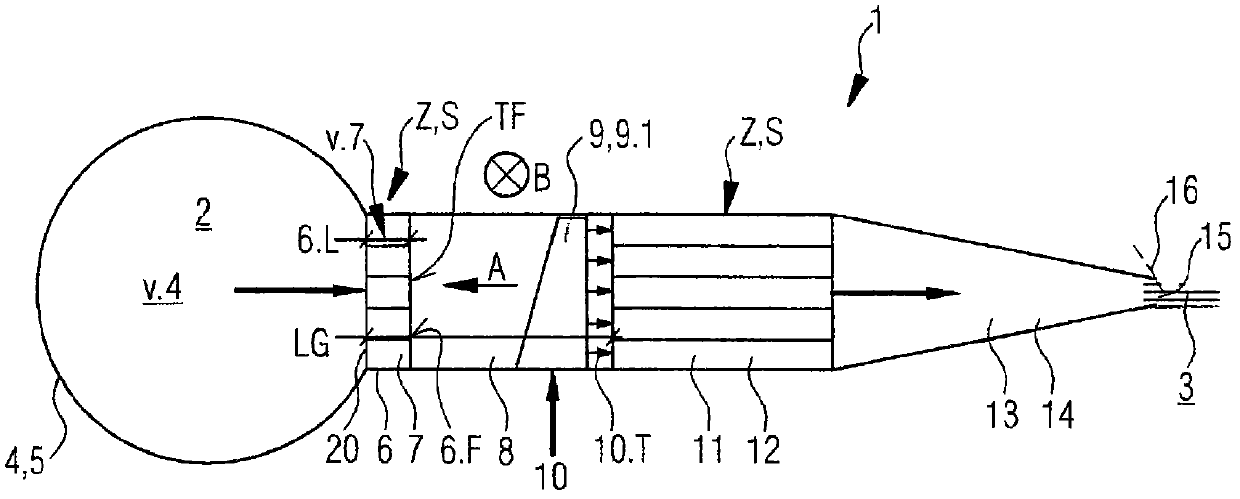

[0030] figure 1 A vertical longitudinal section through an exemplary embodiment of a headbox 1 for a machine for producing a fibrous material web 3 from at least one fibrous material suspension 2 is shown. It goes without saying that the headbox 1 can also be configured as a multilayer headbox for producing a fibrous material web 3 using at least two different fibrous material suspensions. Here, the fibrous material web 3 may in particular be a paper web, a cardboard web or a tissue paper web.

[0031] The headbox 1 has a conveying device 4 for conveying one of the fibrous material suspensions 2, for example in the embodiment of a transverse distribution pipe 5 shown in the figure, or in a not shown here with a large number of hoses. Out of the round dispenser implementation.

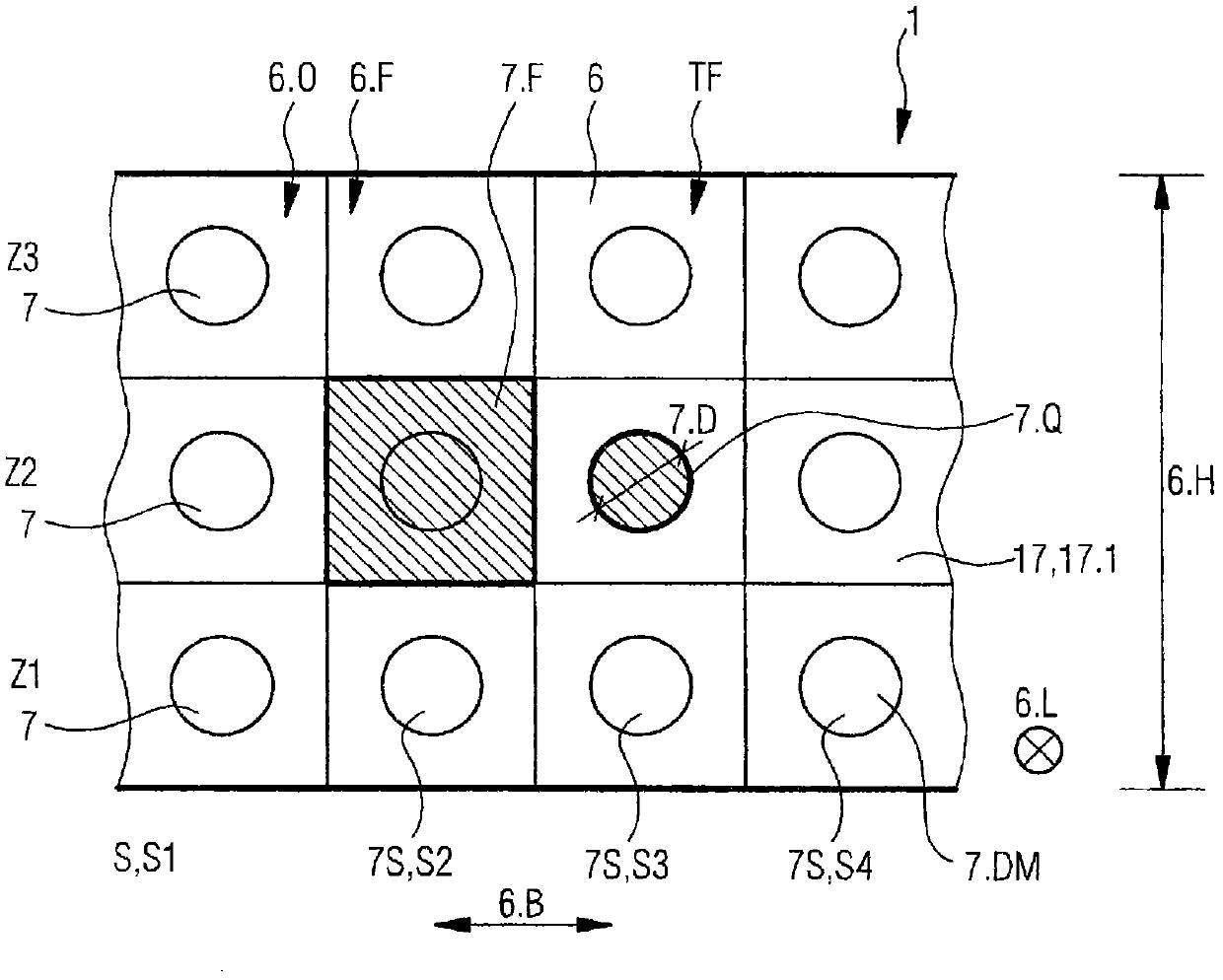

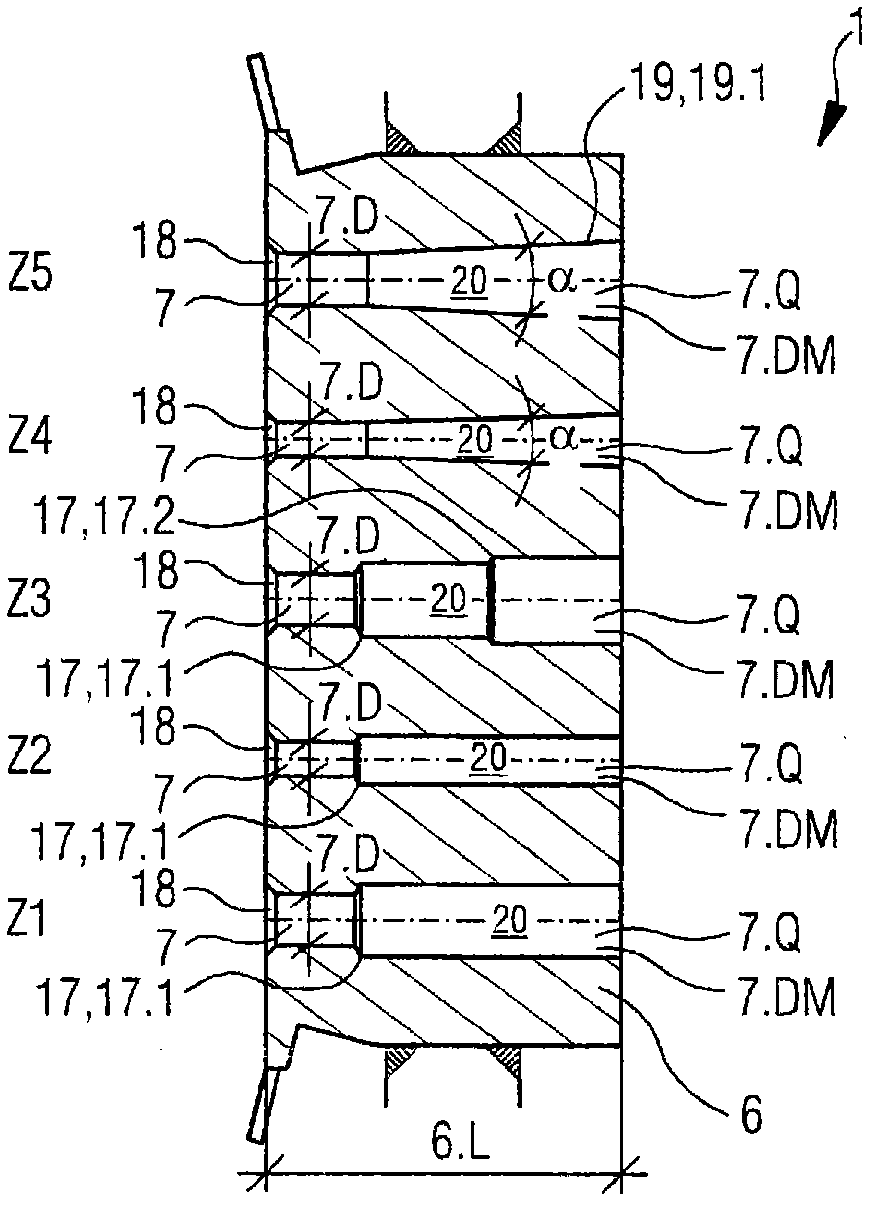

[0032] Following the conveying device 4 downstream is a distribution tube orifice 6 with a large number of channels 7 arranged in rows Z and columns S (cf. figure 2 ). Downstream of the distributio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com