Digital servo controller and corresponding servo control system

A digital servo and controller technology, applied in the field of servo control, can solve problems such as unsatisfactory real-time running speed, high cost, and difficulty in satisfying real-time response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

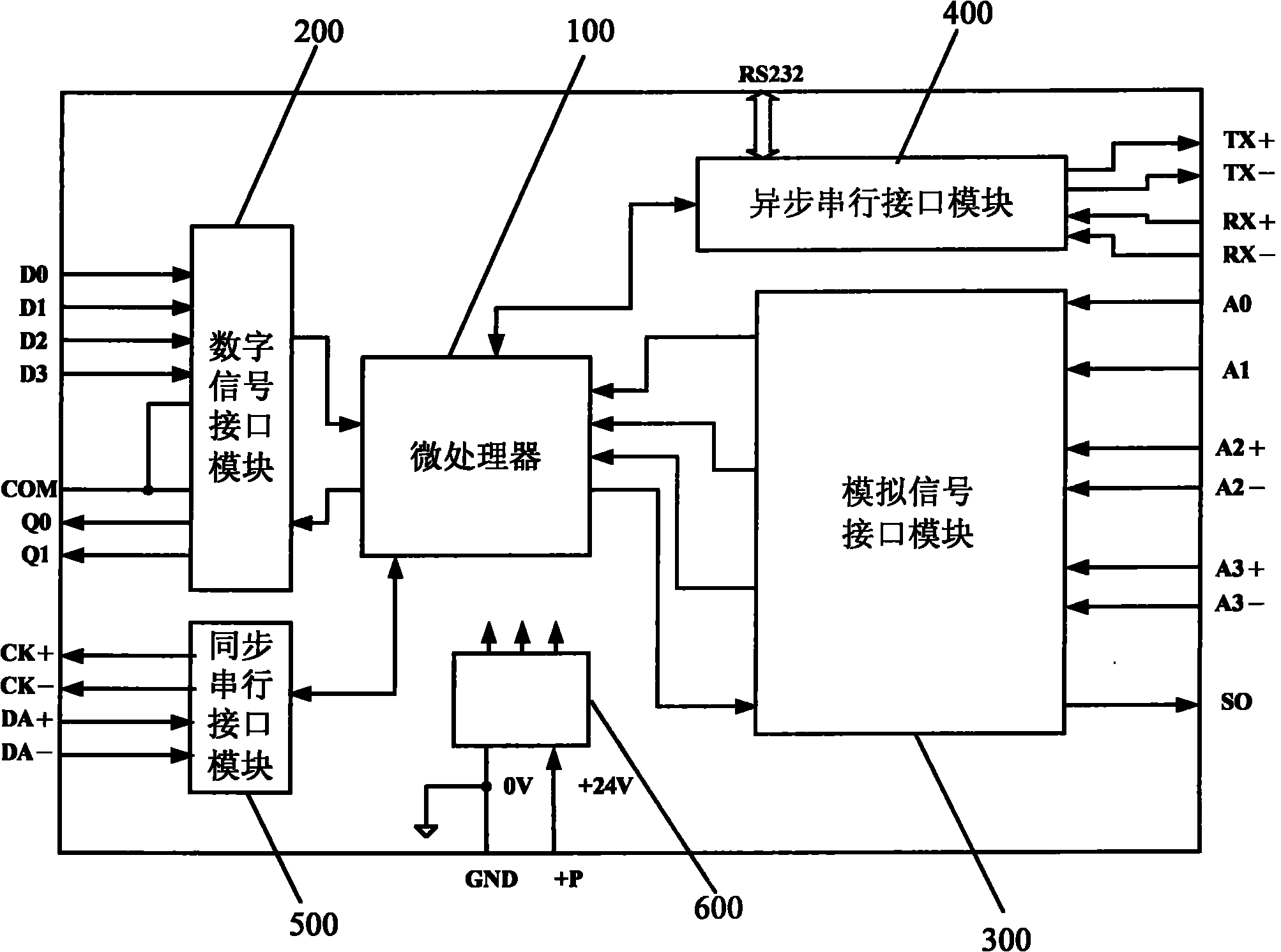

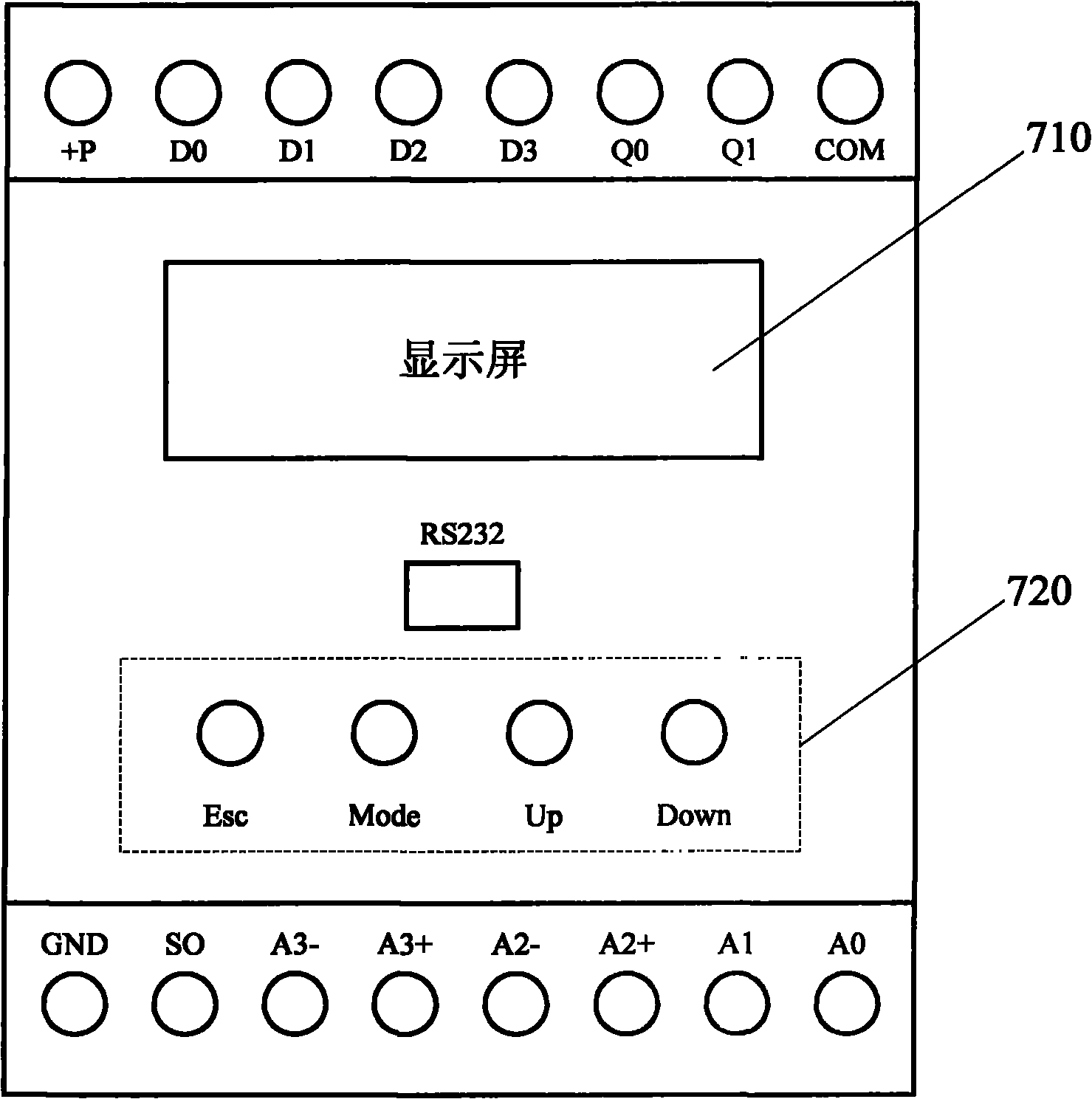

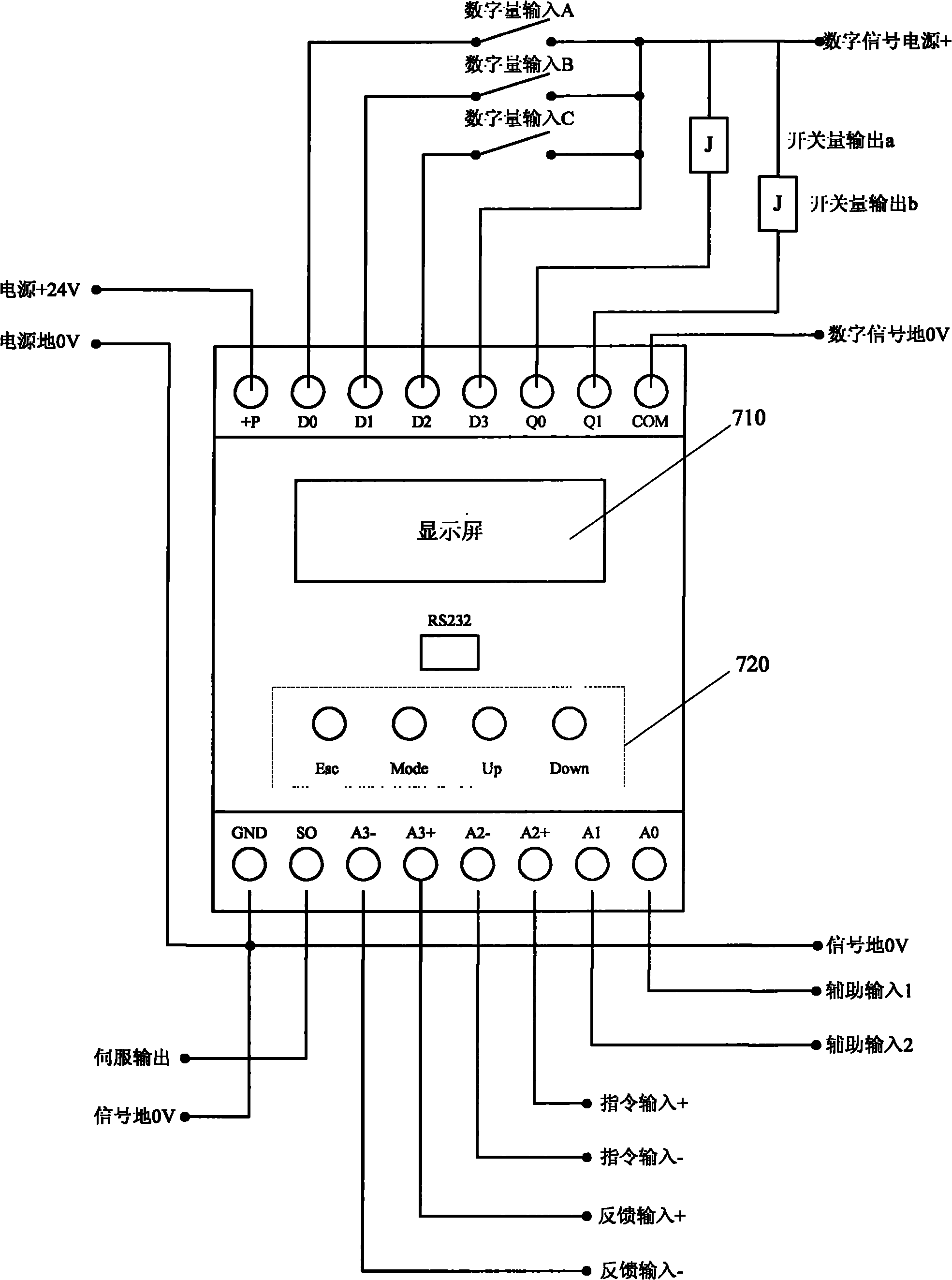

[0023] In order to make the objectives and features of the present invention more comprehensible, the specific embodiments of the present invention will be further described below with reference to the accompanying drawings.

[0024] The inventor fully considered the existing servo control system complex structure, poor reliability in harsh industrial environments, unsatisfactory real-time operation speed, and high cost. Developed and designed a small digital servo controller, which only performs closed-loop control on the motion of an actuator, and then constitutes a distributed servo control system. That is to say, the servo closed-loop control task is completed by a dedicated small digital servo controller. Compared with a centralized servo control system that uses a central controller to take care of all mechanical motion control, the distributed servo control system has excellent real-time performance, fast dynamic speed and precision , The reliability is relatively high.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com