Sensing head of omni-directional wind speed sensor

A technology of sensitive head and sensor, used in the direction of measuring fluid velocity using thermal variables, to achieve the effect of long service life, easy maintenance and little disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

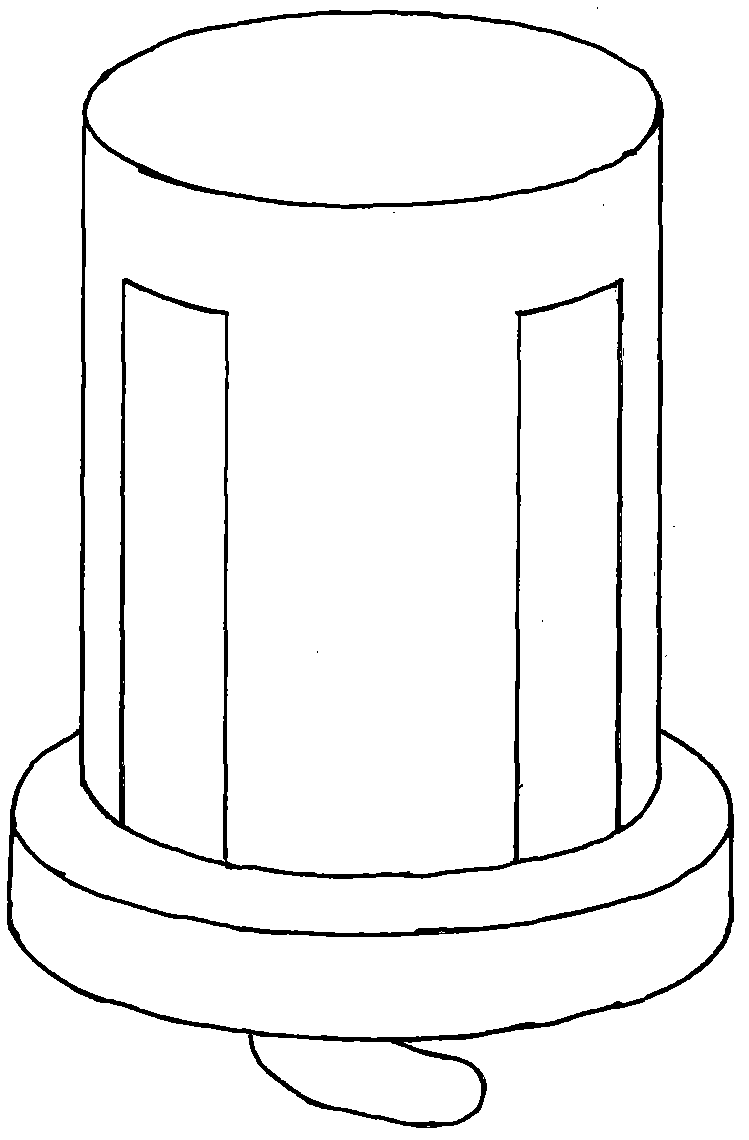

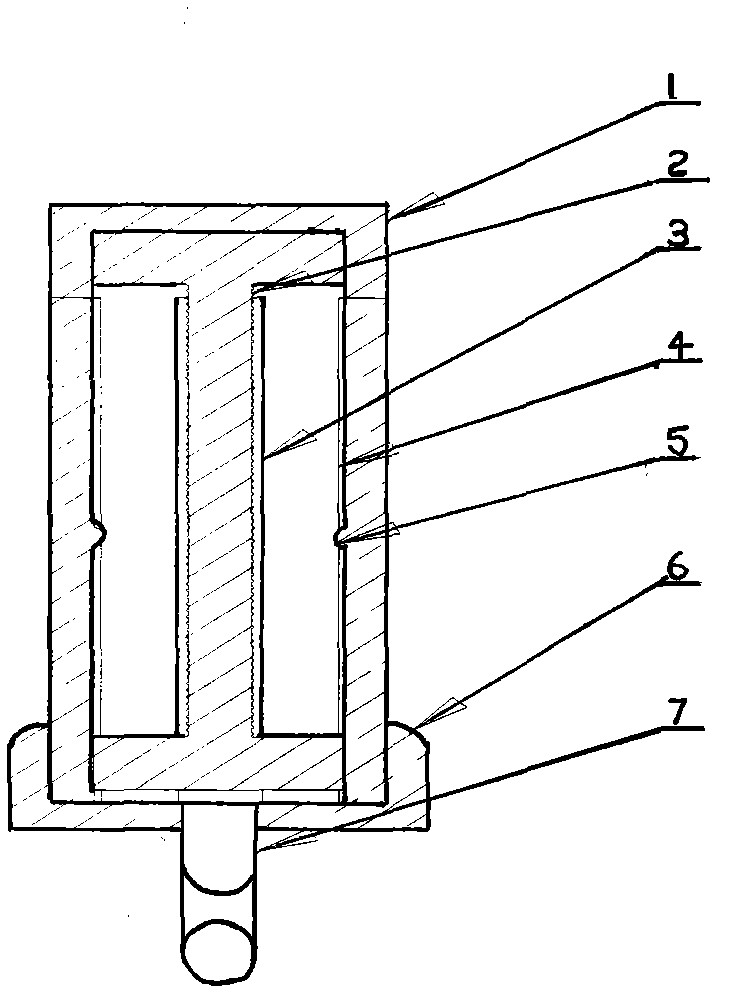

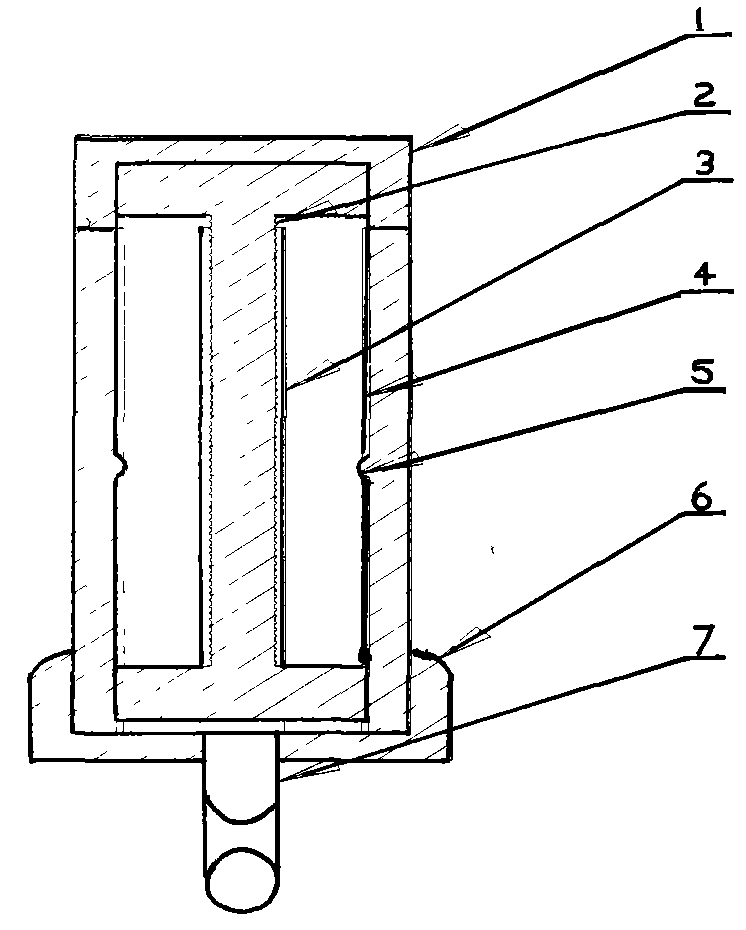

[0031] The full wind direction wind speed sensor sensitive head of the present embodiment, such as Figure 1-2 As shown, it includes sensitive head housing 1, heating element support 2, heating element 3, heat conductor 4, temperature sensor 5, base 6 and cable 7; heating element support 2 and heating element 3 are located in sensitive head housing 1, and generate heat The element 3 is located on the heating element support 2; the temperature sensor 5 is located on the heat conductor 4, the sensitive head housing 1 is provided with a slot, and the end surface of the sensitive head housing 1 is provided with an installation groove in the slot, and the heat conductor 4 is located in the installation groove Inside; the sensitive head shell 1 is installed on the base 6, and the cable 7 installation hole is opened in the axial direction of the sensitive head shell 1 and the bottom of the base 6. The slot is located at a position of 0° parallel to the axial direction of the sensitiv...

Embodiment 2

[0034] The full wind direction wind speed sensor sensitive head of the present embodiment, such as figure 1 As shown in -3, it includes sensitive head housing 1, heating element support 2, heating element 3, heat conductor 4, temperature sensor 5, base 6 and cable 7; heating element support 2 and heating element 3 are located in sensitive head housing 1 , the heating element 3 is located on the heating element support 2; the temperature sensor 5 is located on the heat conductor 4, a slot is provided on the sensitive head housing 1, and an installation groove is provided on the end surface of the sensitive head housing 1 in the slot, and the heat conductor 4 is located on In the installation groove; the sensitive head housing 1 is installed on the base 6, and the cable 7 installation hole is opened in the axial direction of the sensitive head housing 1 and the bottom of the base 6. The slot is located at a 90° position parallel to the axial direction of the sensitive head housi...

Embodiment 3

[0036] The sensitive head of the full wind direction, wind speed and direction sensor of the present embodiment, such as Figure 1-2 As shown, it includes sensitive head housing 1, heating element support 2, heating element 3, heat conductor 4, temperature sensor 5, base 6 and cable 7; heating element support 2 and heating element 3 are located in sensitive head housing 1, and generate heat The element 3 is located on the heating element support 2; the temperature sensor 5 is located on the heat conductor 4, the sensitive head housing 1 is provided with a slot, and the end surface of the sensitive head housing 1 is provided with an installation groove in the slot, and the heat conductor 4 is located in the installation groove Inside; the sensitive head shell 1 is installed on the base 6, and the cable 7 installation hole is opened in the axial direction of the sensitive head shell 1 and the bottom of the base 6. The slot is located at a position 270° parallel to the axial dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com