Automatic weighing method and device for various materials

A technology of automatic weighing and measuring method, applied in the direction of measuring device, weighing, weighing equipment for continuous material flow, etc., can solve the problems of low efficiency, time-consuming and labor-intensive, and high labor intensity of operators

Active Publication Date: 2013-06-12

SHANXI TAIGANG STAINLESS STEEL CO LTD

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, iron and steel enterprises have higher and higher requirements for production refinement. At the same time, with the construction of information system, it is required to provide automatic classification and measurement data according to materials, and to make statistics according to hours, shifts, and days. However, existing devices (belt scales, etc.) only It can display the instantaneous flow rate and calculate the cumulative amount of the transported materials, which cannot meet the requirements. It can only rely on manual collection of raw data, and then conduct statistics and summary. Human factors in the whole process cause data accuracy to be low, time-consuming, laborious, and inefficient.

At present, the material measurement data collection is obtained by the operator after reading the weight data of the belt scale instrument and calculating it. The main problems are as follows: 1. When the belt scale measures multiple materials, it is necessary to manually read the belt scale instrument when changing the material type Record the weight data, otherwise it is impossible to distinguish what kind of material weight the measurement data is, and the labor intensity of the operator is high when multiple materials are frequently changed

2. When it is necessary to count the material measurement data according to hours, shifts, and days, it is necessary to manually read the weight data of the belt scale instrument according to the time frequency, and then calculate and summarize. Due to the deviation of the operator's timing, data errors are caused

3. When multiple belt scales measure multiple materials, it cannot be completed manually

Both of the above two systems need to use specific special equipment to distinguish and identify materials, and only focus on material identification and classification measurement. The versatility and easy maintenance of the equipment restrict the applicability of the system, and do not involve the transmission and statistics of material measurement data. Management and other issues

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

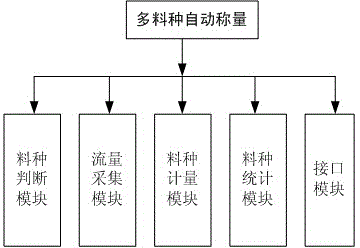

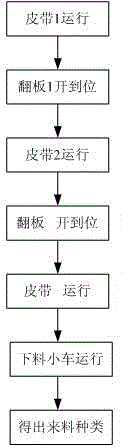

Multi-material automatic weighing device is an automatic weighing detection technology, which includes an electronic belt scale, a programmable controller, a computer, the output of the electronic belt scale is connected to the input of the programmable controller, and the output of the programmable controller Connect to the input of the computer, connect the output of the computer to the input of the server, connect the output of the server to the input of the display, the electronic belt scale collects the flow signal of the material transported by the belt; the programmable controller collects the running signal of the belt, and collects the instantaneous Quantity, material identification is carried out through the material type judgment module, and classification measurement is performed through the material type measurement module; the computer runs the material type statistics module, and the material measurement data is classified and queried according to the number of shifts and days; the material measurement data is calculated through the interface module. The data is automatically uploaded to the information system. The invention realizes automatic classification and measurement according to materials, and provides automatic statistics and query functions and automatic data uploading at the same time.

Description

technical field [0001] The invention relates to an automatic weighing method and device for multiple materials, belonging to the technical fields of computer technology, automatic control, and weighing detection. Background technique [0002] In the production process of iron and steel enterprises, the measurement data of production input and product receipt is one of the important data of cost accounting. In the pre-iron (mining, coking, sintering, ironmaking) system, there are many kinds of materials for production feeding and product receiving, and most of them are transported by belts. The raw data of these materials mainly come from the belt scales installed on site. At present, iron and steel enterprises have higher and higher requirements for production refinement. At the same time, with the construction of information system, it is required to provide automatic classification and measurement data according to materials, and to make statistics according to hours, s...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01G11/00G01G11/18

Inventor 卢海宁宋正中杨斌宋迎春

Owner SHANXI TAIGANG STAINLESS STEEL CO LTD

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com