Vibration attenuation and noise reduction pad and motor installation structure of range hood

A technology of installation structure and sound-absorbing pad, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of incapability of electromagnetic sound silencing, high cost, application limitations, etc., to prevent circumferential slip, attenuate sound amplification, low The effect of the natural frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

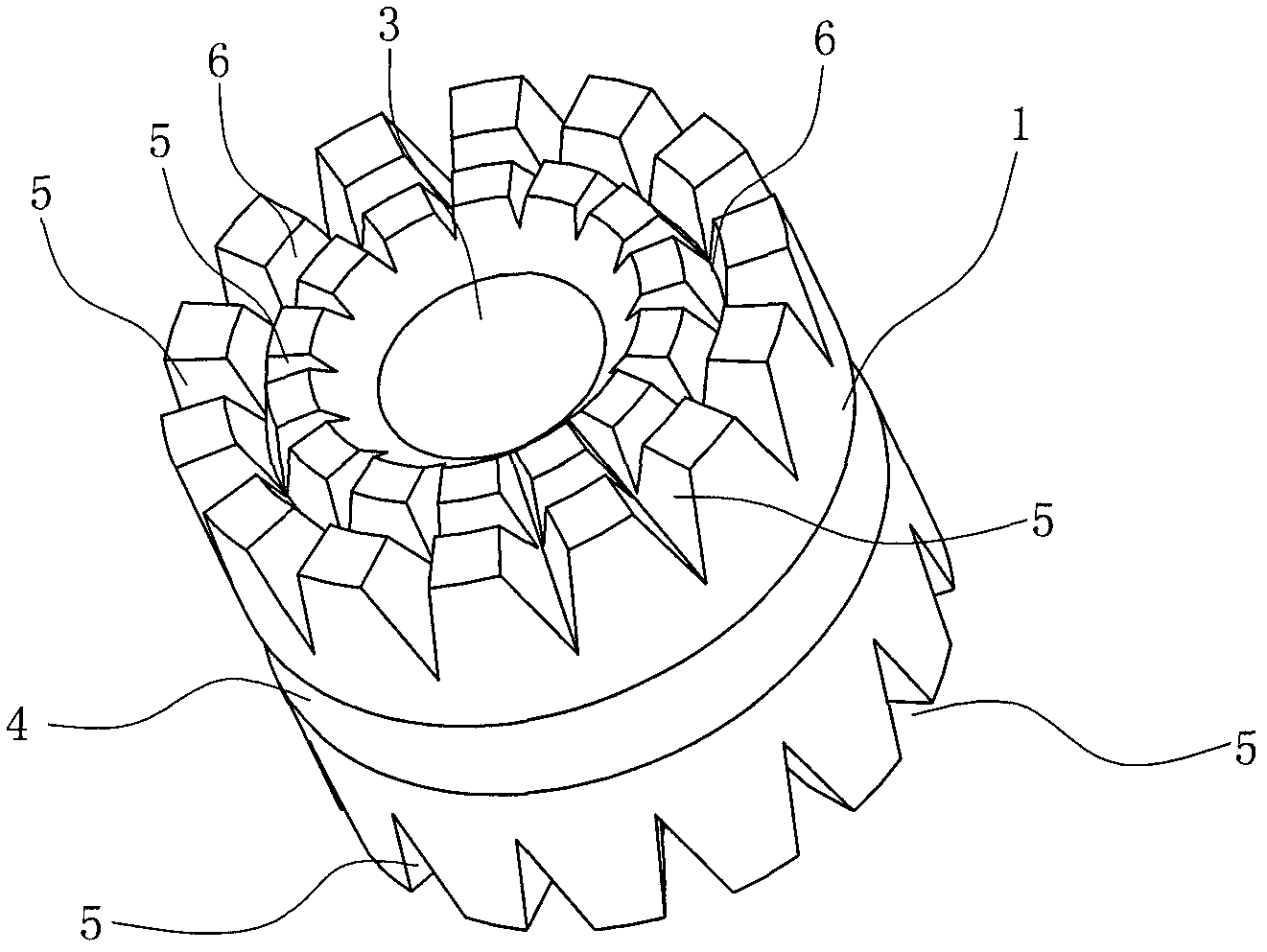

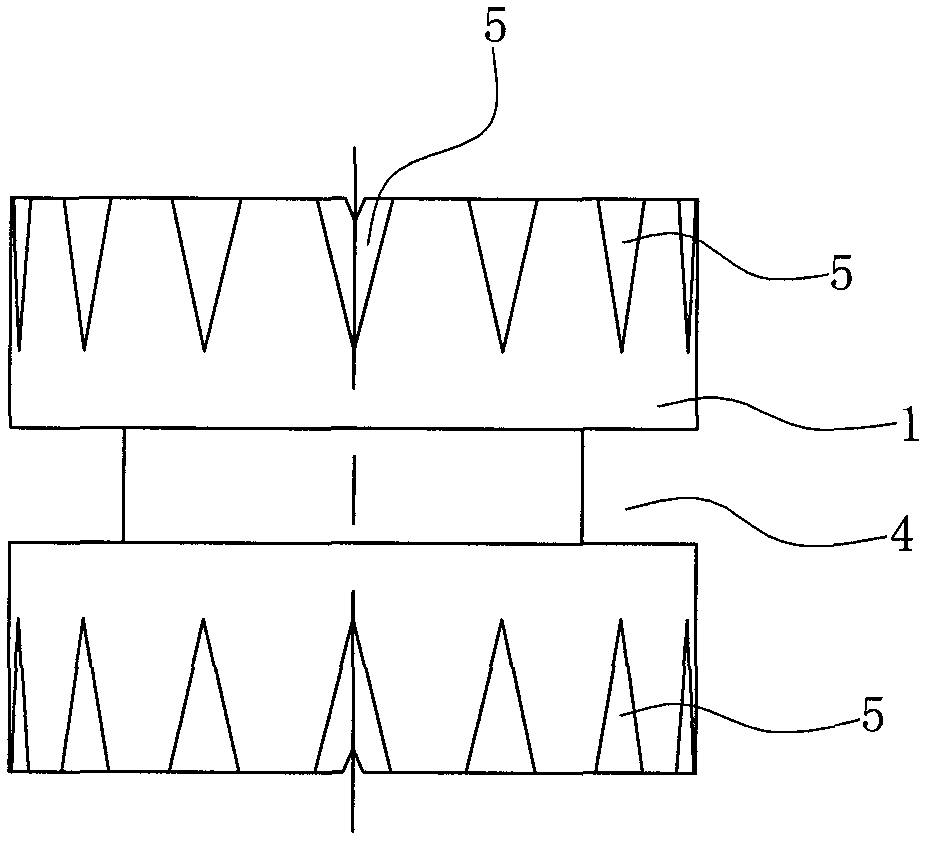

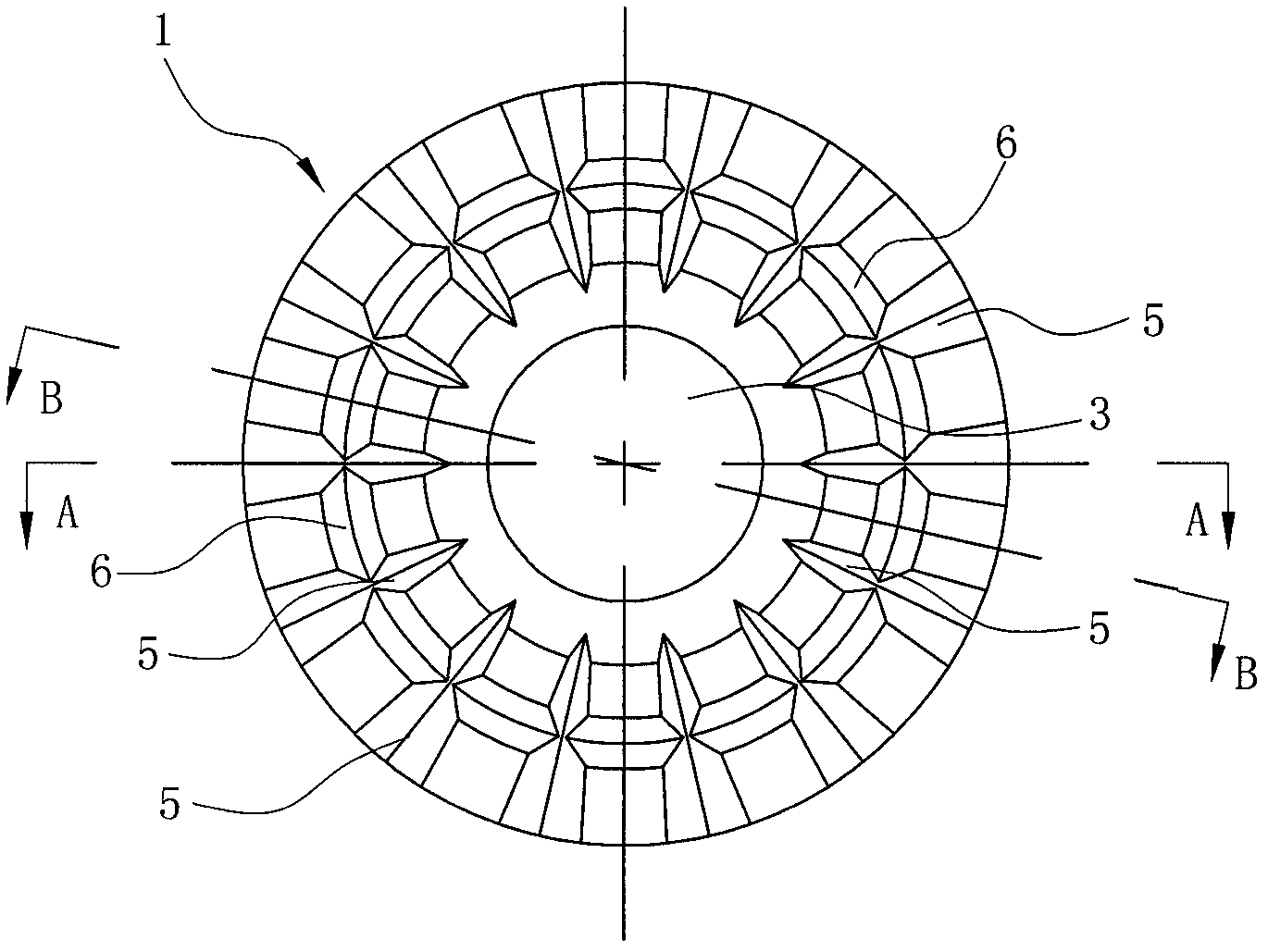

[0031] Such as Figure 1~5 Shown is a schematic structural view of the vibration-damping and sound-absorbing pad of the present invention.

[0032] A vibration-damping and sound-absorbing pad, comprising a columnar body 1, in which there is a through-hole 3 through which the mounting screw 2 passes through in the axial direction, and the edges of the upper and lower openings of the through-hole 3 are provided with Chamfering, an annular groove 4 is formed on the peripheral surface of the middle part of the body 1 .

[0033] The upper end surface and the lower end surface of the main body 1 are provided with a plurality of radial notches 5 at intervals along the circumference, and each radial notch 5 radially penetrates the peripheral wall of the main body 1 . The radial notch 5 gradually shrinks inward along the direction of the end surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com