Mixed flow type water turbine with ultralow specific speed and high efficiency for cooling tower special belt water distributer

A technology with a water distributor and a cooling tower, which is applied in the direction of reaction engines, machines/engines, hydroelectric power generation, etc., can solve the problems of the shape, size and structure of the flow channel of the Francis turbine, and the complicated installation process, etc., to achieve compact structure, Stable operation and low noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

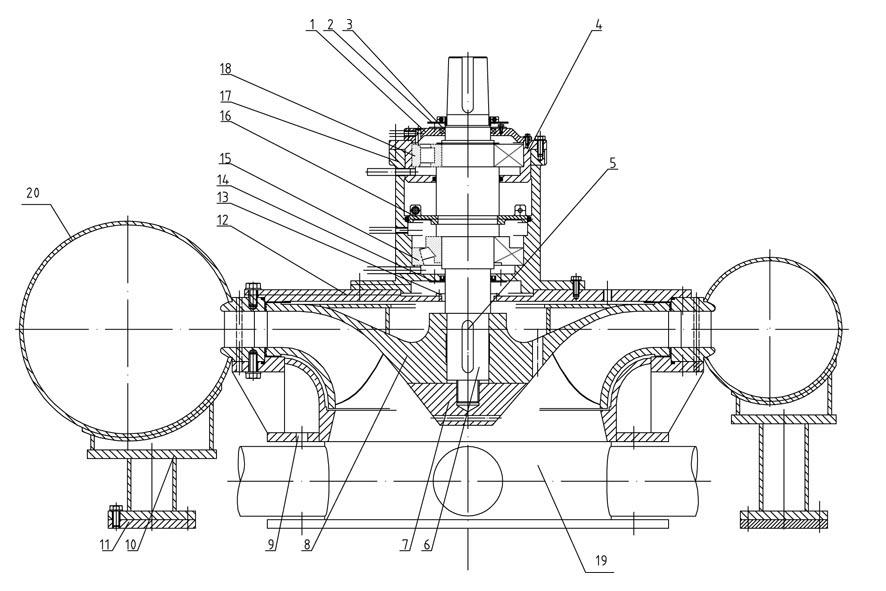

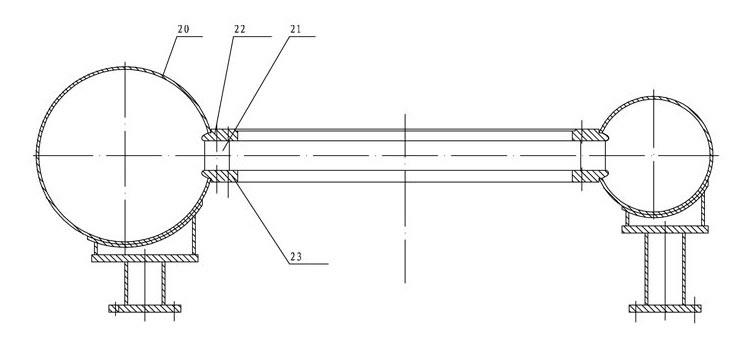

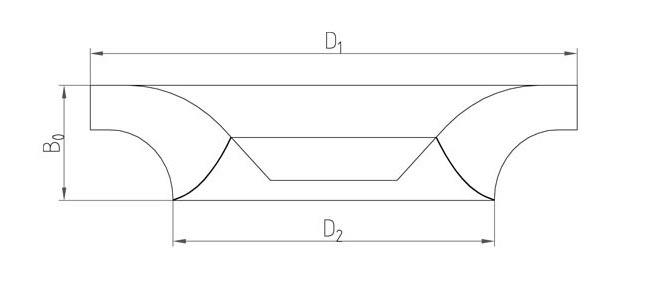

[0014] Ultra-low specific speed and high-efficiency Francis turbine with water distributor for cooling tower, which includes runner 8, main shaft 6, bearing device, seat ring 10, bottom ring 9, cover plate 12, bearing device includes first gland 3, bearing Cover 1, bearing cup 4, radial bearing 18, snap ring 16, thrust bearing 15, second gland 14, wherein the first gland 3, bearing cap 1, bearing cup 4, radial bearing 18, snap ring 16, The thrust bearing 15 and the second gland 14 are installed on the main shaft 6 from top to bottom in turn, and the radial bearing 18 is in the bearing cup 4, the thrust bearing 15 is directly installed in the sleeve 17, and the bearing cup 4 is fastened by bolts. On the sleeve 17, the bearing cover 1 is equipped with a skeleton seal, which is sealed with the first gland 3, and the water throwing ring 2 is installed above the first gland 3, and fixed on the main shaft 6 through a half-flange. The bearing device is placed in the sleeve 17, the sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com