Multifunctional combined type white spirit filtering machine

A filter and liquor technology, applied in the preparation of alcoholic beverages, etc., can solve the problems of turbid flocs, loss of light, etc., and achieve the effect of clear and transparent wine body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

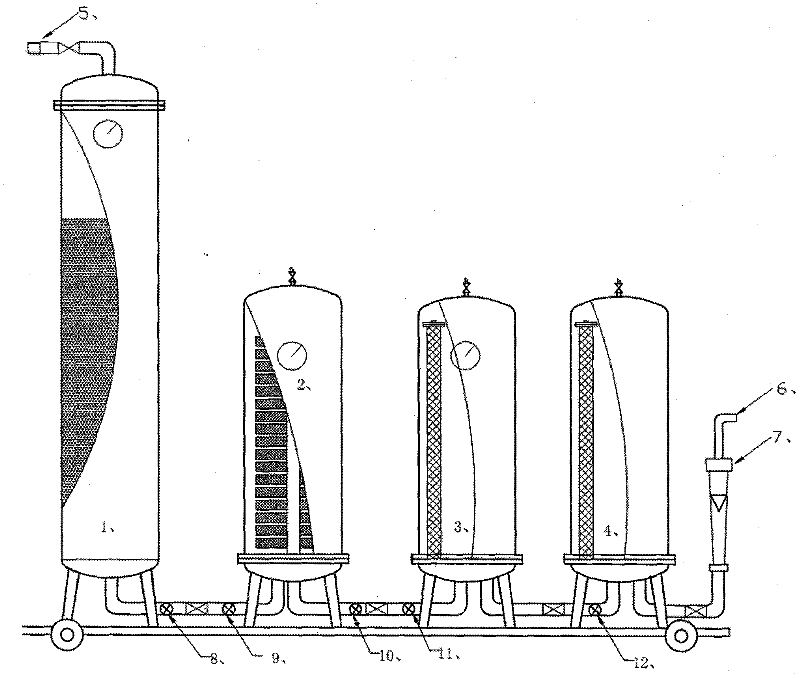

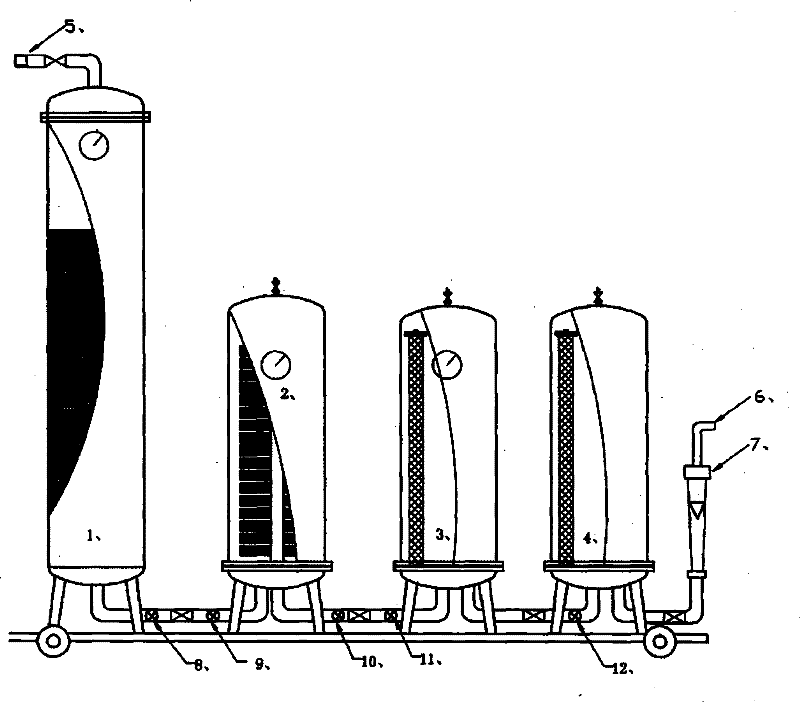

[0012] Press the wine into the primary filter by pressurizing the wine pump, and use the principle of liquor medium adsorption to remove ethyl oleate, ethyl palmitate and ethyl linoleate produced by brewing, and to remove odors. When entering the secondary filtration, the filter membrane is used to intercept the larger particulate matter and high-alcohol oil in the wine. Three-stage filtration further intercepts fine particles and colloidal substances. The four-stage filter is equipped with a 0.1 micron special filter element, which can intercept the transparent substances that cannot be seen by the naked eye, so that the wine body is clear and transparent. Then enter the filling line to bottle the finished product.

[0013] Technical Description

[0014] Primary filter built-in special filter medium for liquor

[0015] The secondary filter is equipped with a special membrane for liquor

[0016] Three-stage filter built-in 65X760 hot melt filter membrane 0.3um

[0017] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com