Novel environment-friendly synergistic flame retardant and preparation method thereof

A synergistic flame retardant and environmental protection technology, which is applied in the field of flame retardant additives and its preparation, can solve the problems of stable processing and environmental protection conditions that cannot be widely used, unsatisfactory synergistic flame retardant effects, and serious environmental pollution. The effect of optimization of cost, good insulation, mechanical properties and processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

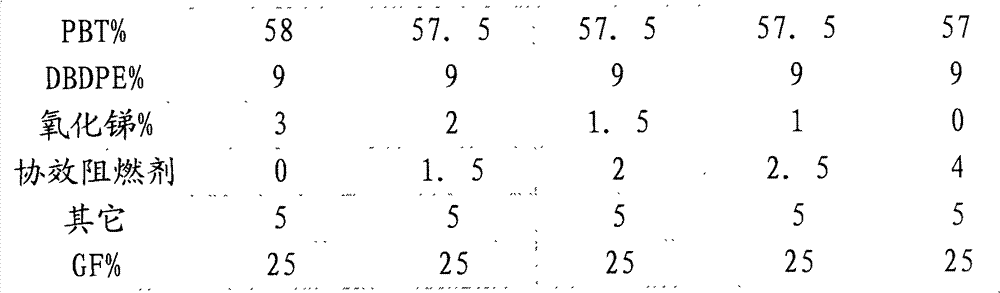

[0034] Table 1- PBT flame retardant modification ratio; wherein synergistic flame retardant formula: nano-silica: 10%, magnesium oxide: 80%, aluminum oxide: 3%, silane coupling agent: 1%, pentaerythritol tetrahard Fatty acid esters: 6%.

[0035]

[0036]

Embodiment 2

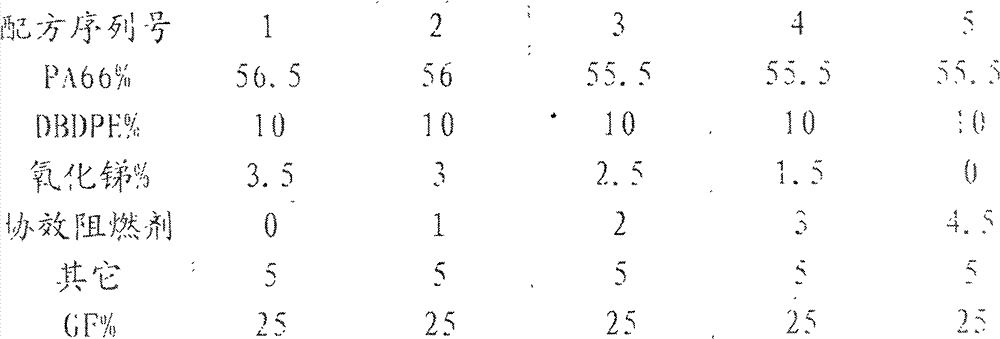

[0038] Table 2-PA66 flame retardant modification ratio; wherein synergistic flame retardant formula: nano-silica: 15%, magnesium oxide: 70%, aluminum oxide: 5%, silane coupling agent: 2%, pentaerythritol tetrahard Fatty acid esters: 8%.

[0039]

Embodiment 3

[0041] Table 3-ABS flame retardant modification ratio; wherein synergistic flame retardant formula: nano-silica: 13%, magnesium oxide: 75%, aluminum oxide: 4%, silane coupling agent: 2%, pentaerythritol tetrahard Fatty acid esters: 6%.

[0042]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com