Telescopic decanter for continuous loop-type reaction tank

A reaction tank and decanter technology, which is applied in the field of telescopic decanters for continuous split-type reaction tanks, can solve the problem of shortened cleaning and replacement cycles of filter parts, inability to perform economical and reasonable sewage and waste water treatment, and blockage of filter parts. and other problems to achieve the effect of ensuring the strength of the setting, accurately discharging the work, and realizing the failure or malfunction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Hereinafter, the present invention for achieving the above-mentioned objects will be described in detail with reference to the drawings.

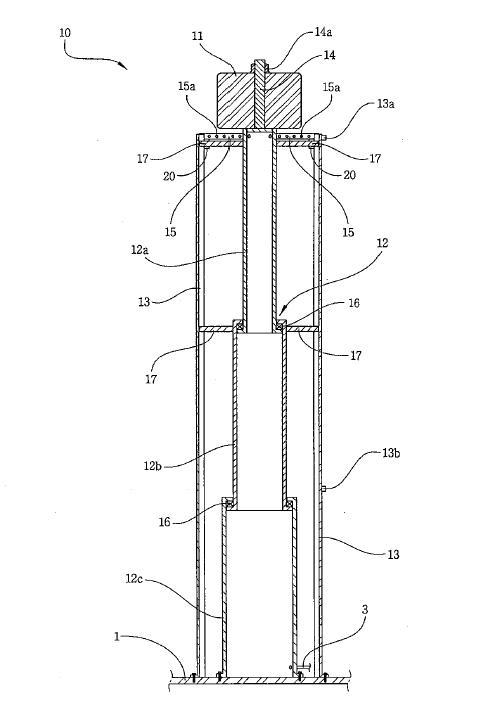

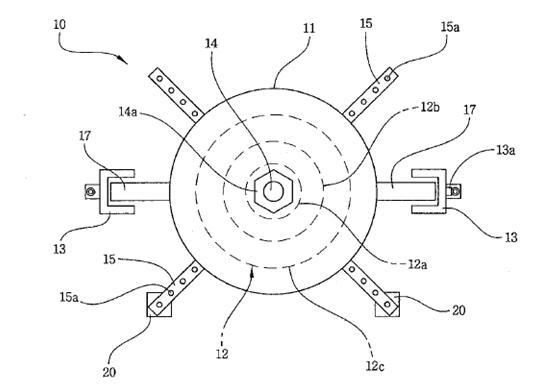

[0052] The telescopic decanter 10 according to the present invention, such as figure 2 and image 3 Shown, including:

[0053] (1) A telescopic tube (Telescope-rod) 12, the telescope-rod 12 is arranged in a vertical direction at the bottom of the continuous split reaction tank 1 for providing a discharge channel for the treated water;

[0054] (2) The buoy object 11 is connected to the upper end of the telescopic tube 12 and used to guide the telescopic work of the telescopic tube 12.

[0055] Such as figure 2 and image 3 As shown, the telescopic tube 12 is formed by connecting three tubes of a first tube 12a on the upper end side, a second tube 12b in the center, and a third tube 12c on the lower end side, but it can be configured according to the decanter 10 The required height and the discharge amount of treated water determine the num...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com