Lightweight coach body structure and section thereof

A passenger car body structure and body technology, which is applied in the superstructure, vehicle components, transportation and packaging, etc., can solve the problems of body weight, and achieve the effects of reducing body weight, increasing passenger capacity, and reducing industrial energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

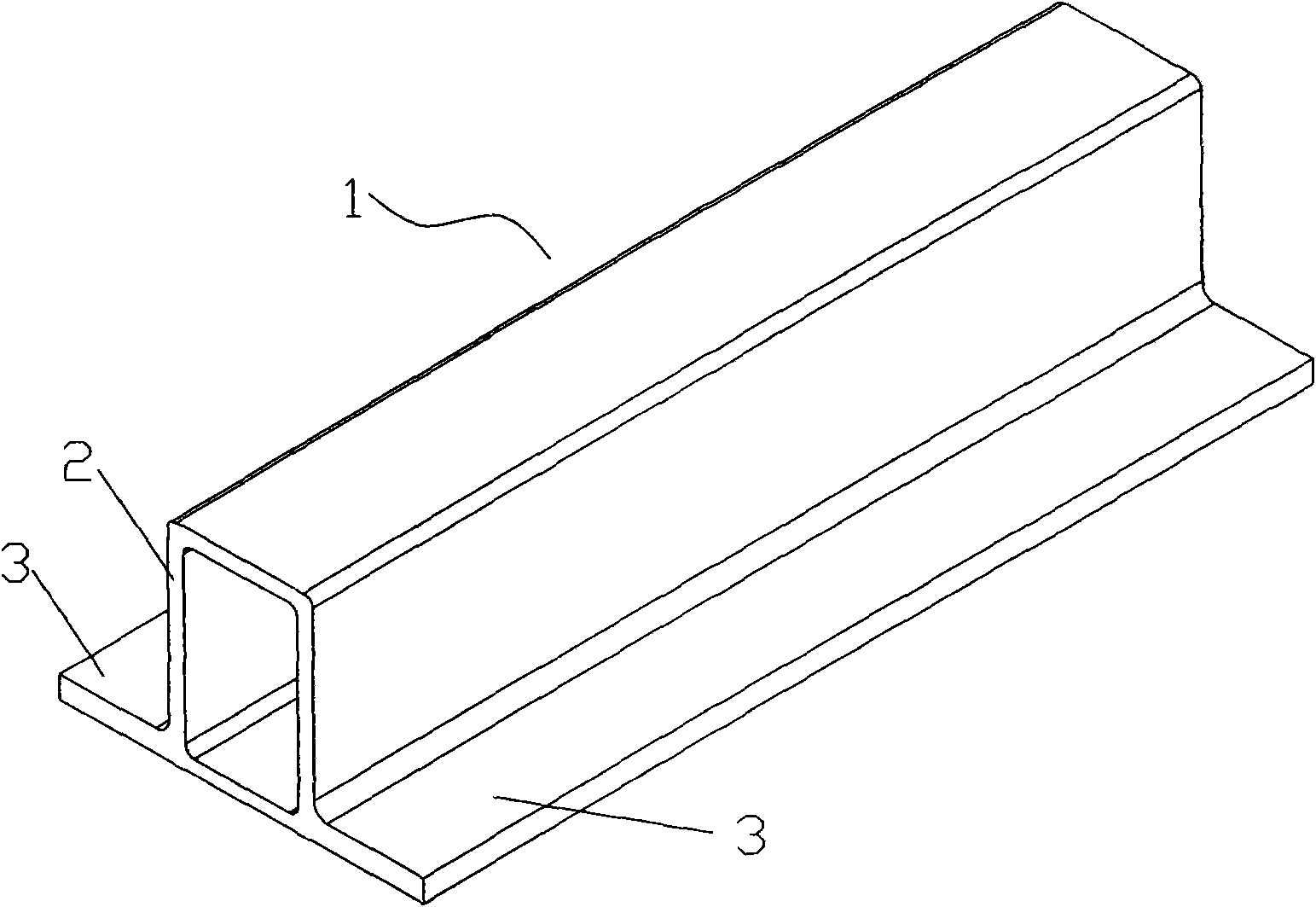

[0023] Such as figure 1 As shown, the cross-sectional shape of the aluminum alloy profile 1 is a hollow rectangular ring 2, and the short sides of one side of the rectangle extend outwards from both ends to form wings 3, wherein the ratio of the short side to the long side of the rectangle is 1: 2. The wall thickness of the rectangular ring 2 and the thickness of the wings 3 are 3mm.

[0024] In other embodiments of the present invention, the ratio of the short side and the long side of the rectangle can also be 1:1, or 1:3, and the wall thickness of the rectangular ring and the thickness of the wings can also be 8 millimeters, or 5 mm.

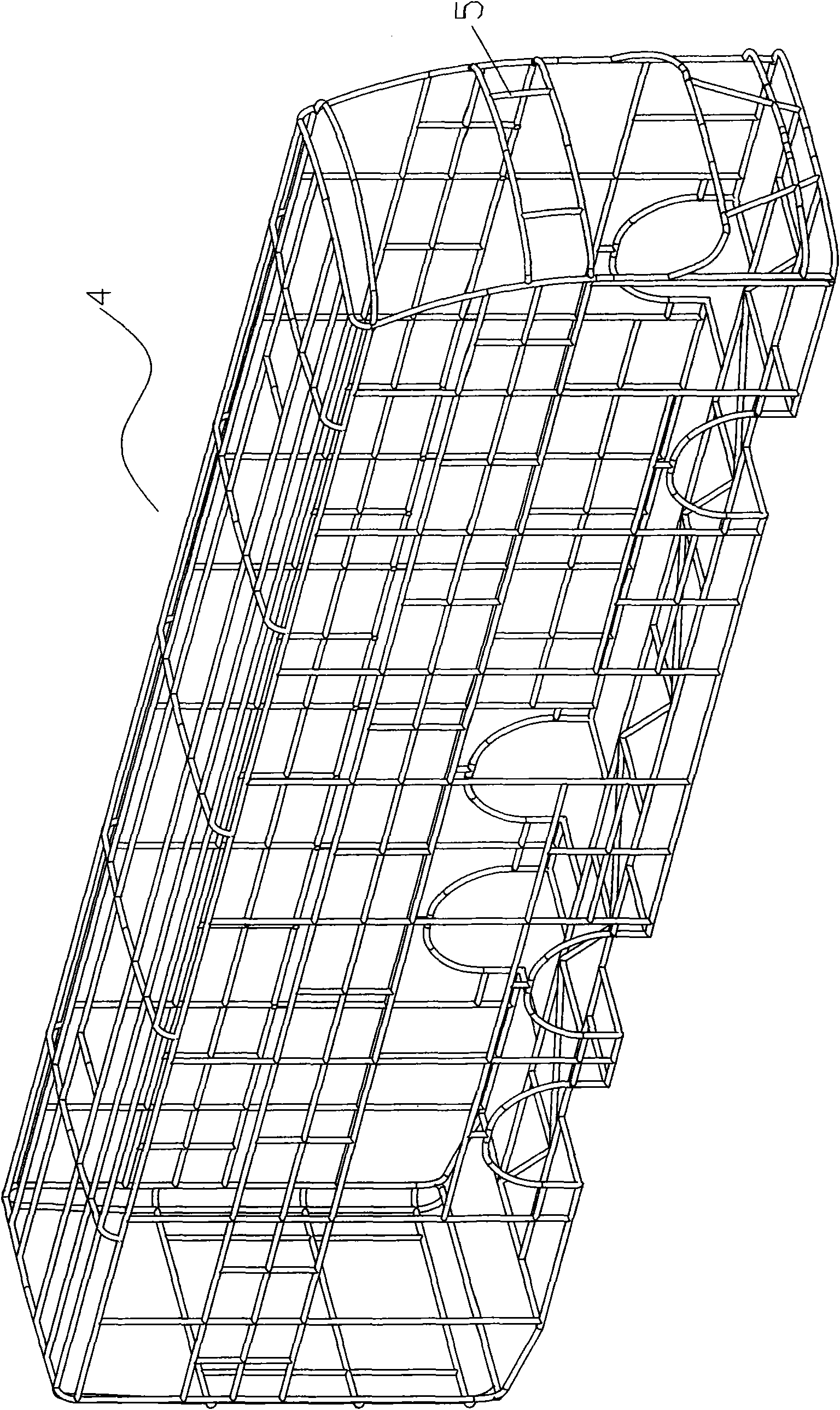

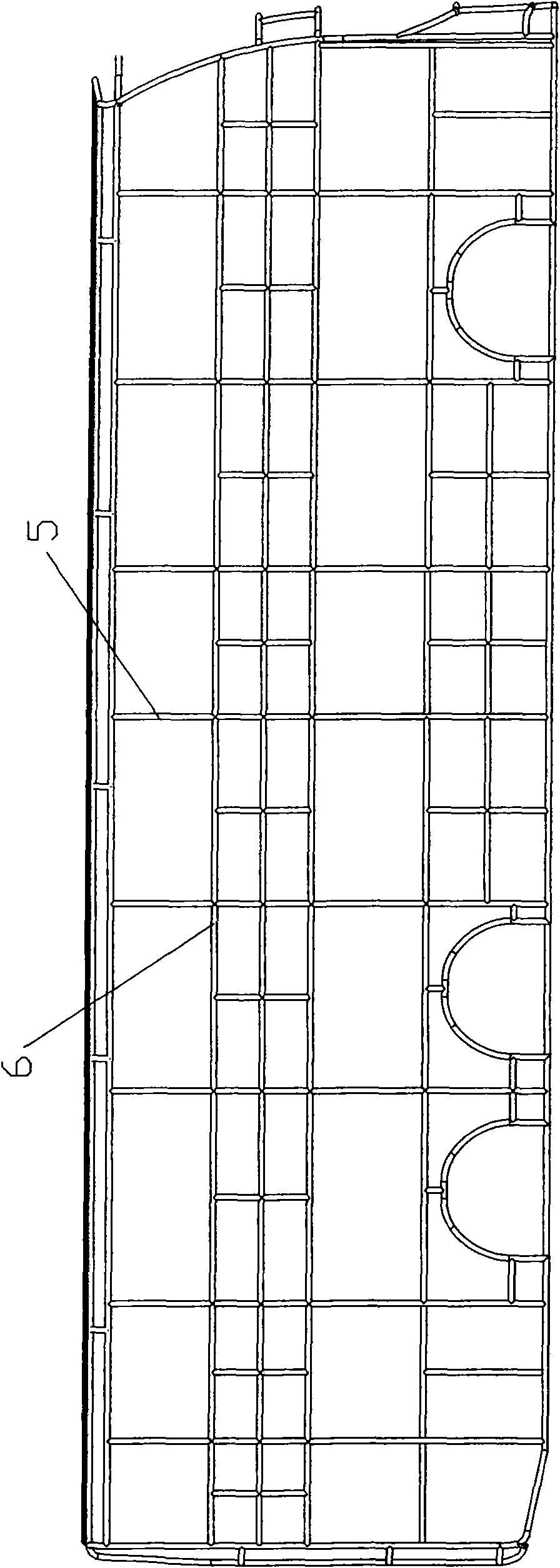

[0025] Such as figure 2 As shown, the bus body 4 is a full load-bearing body surrounded by chassis trusses, surrounding frames and top arch frames. Among them, the left side frame and the right side frame in the surrounding frame are riveted with the chassis truss, and the front wall frame, the rear wall frame and the top arch frame in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com