Fixture special for grinding and machining of HSK (Hohl Schaft Kegel) shank series cutter

A technology of grinding processing and special fixtures, which is applied in the direction of grinding workpiece supports, manufacturing tools, and other manufacturing equipment/tools, etc., which can solve the problems of unfavorable automatic control system high speed, low machine tool clamping accuracy, and lack of processing special fixtures, etc. , to achieve good high-speed locking, fast automatic tool change, and improve the effect of repeated positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

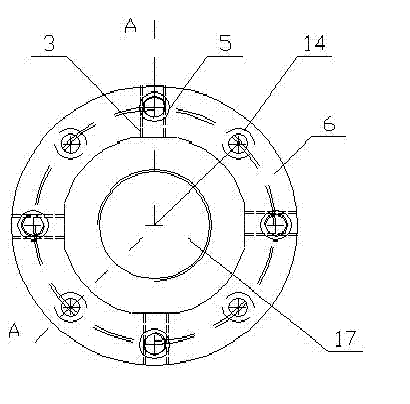

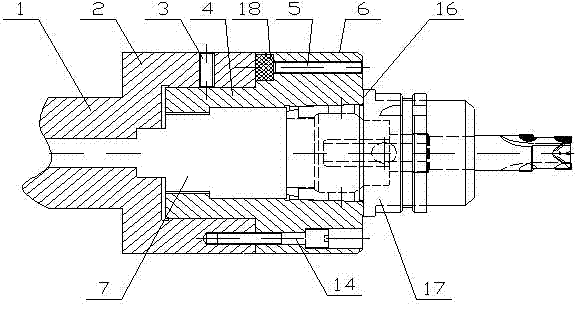

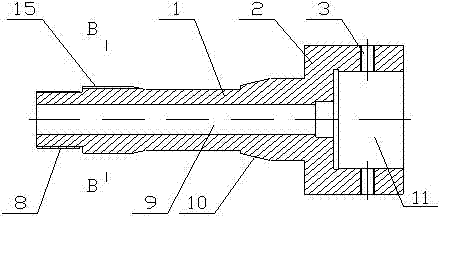

[0027] Depend on Figure 1-Figure 7 The special grinding fixture for cutting tools of the HSK shank series shown includes a flange shaft connected to the main shaft of the machine tool and an HSK adjustment mechanism. The HSK adjustment mechanism includes a horizontally arranged convex block, and the convex block is provided with a cavity 13 along the central axis. , the cavity 13 is a through hole in the convex block, and the convex block is divided into a protrusion 4 on the left side and a bottom block 6 on the right side, and the cavity part facing the right end surface of the bottom block 6 in the cavity 13 is the same as The tapered shape of the HSK handle fits and thus forms the tapered surface 12 , the tapered surface 12 is for later matching with the HSK handle, and the HSK handle is connected to the HSK tool 17 . The bottom block 6 is provided with an axial adjustment screw hole; the flange shaft includes the flange 2 and the connecting shaft 1 fixed horizontally on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com