Soldering apparatus

A technology for soldering and substrates, which is applied to welding equipment, assembling printed circuits with electrical components, lighting and heating equipment, etc. It can solve the problem that users cannot leave, do not have the means to notify users, and pass the alarm as a substrate falling error. It can prevent errors in curve measurement and prevent mistransmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, the best mode for carrying out the present invention (hereinafter referred to as an embodiment) will be described.

[0026] [Structure example of reflow soldering device]

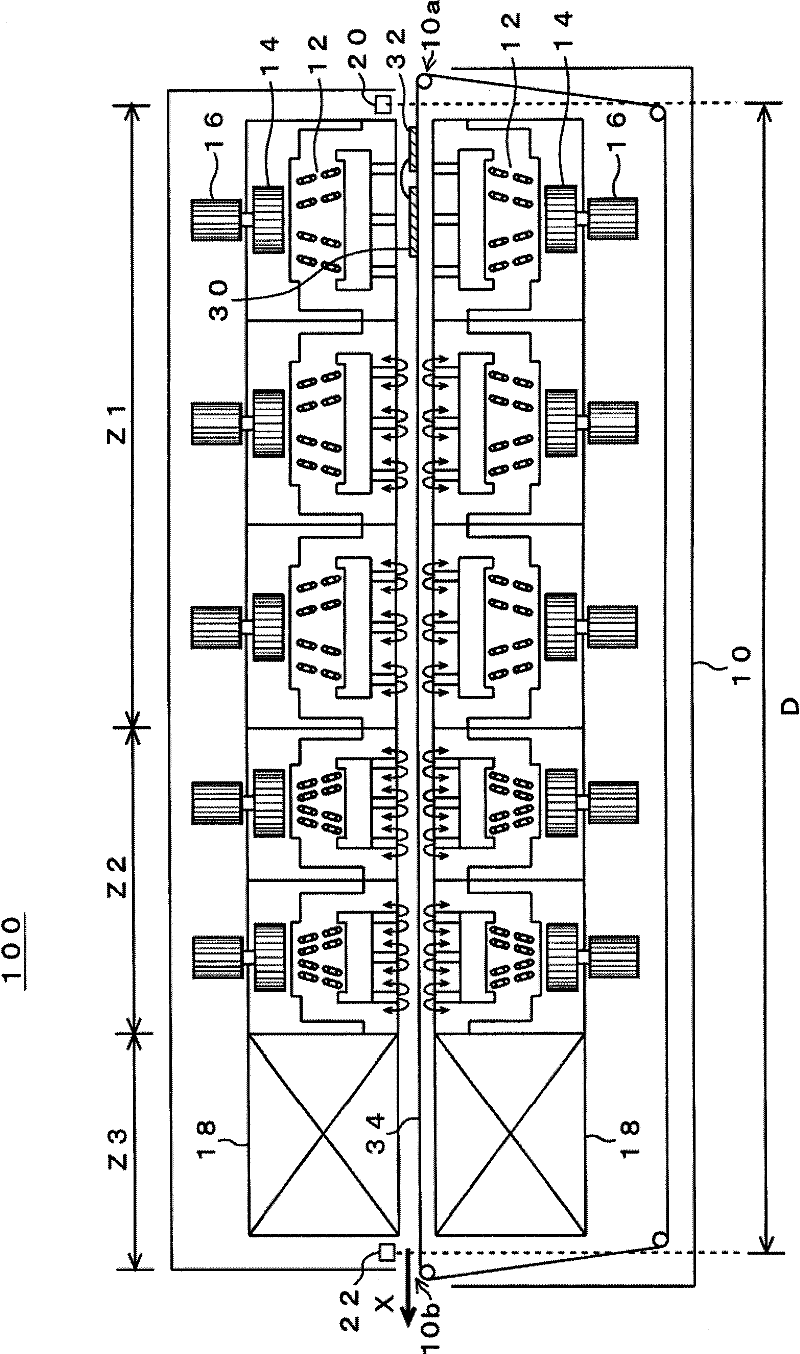

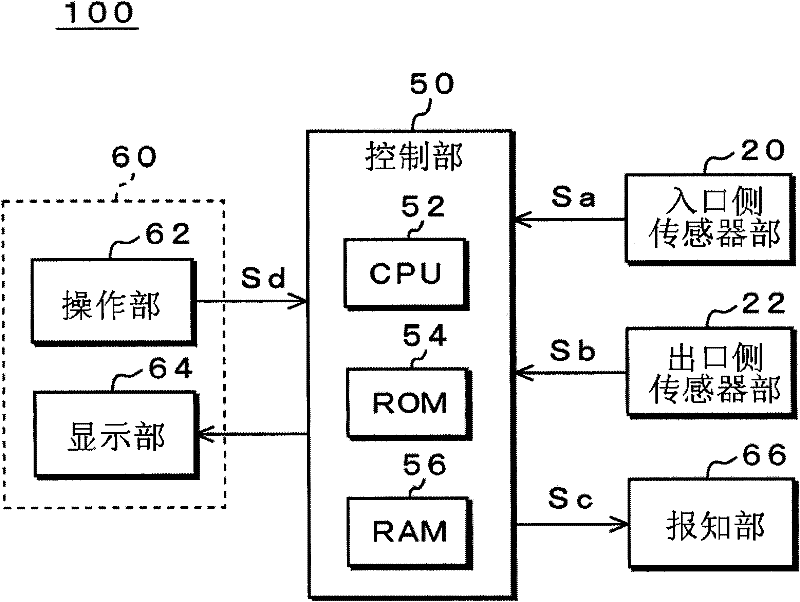

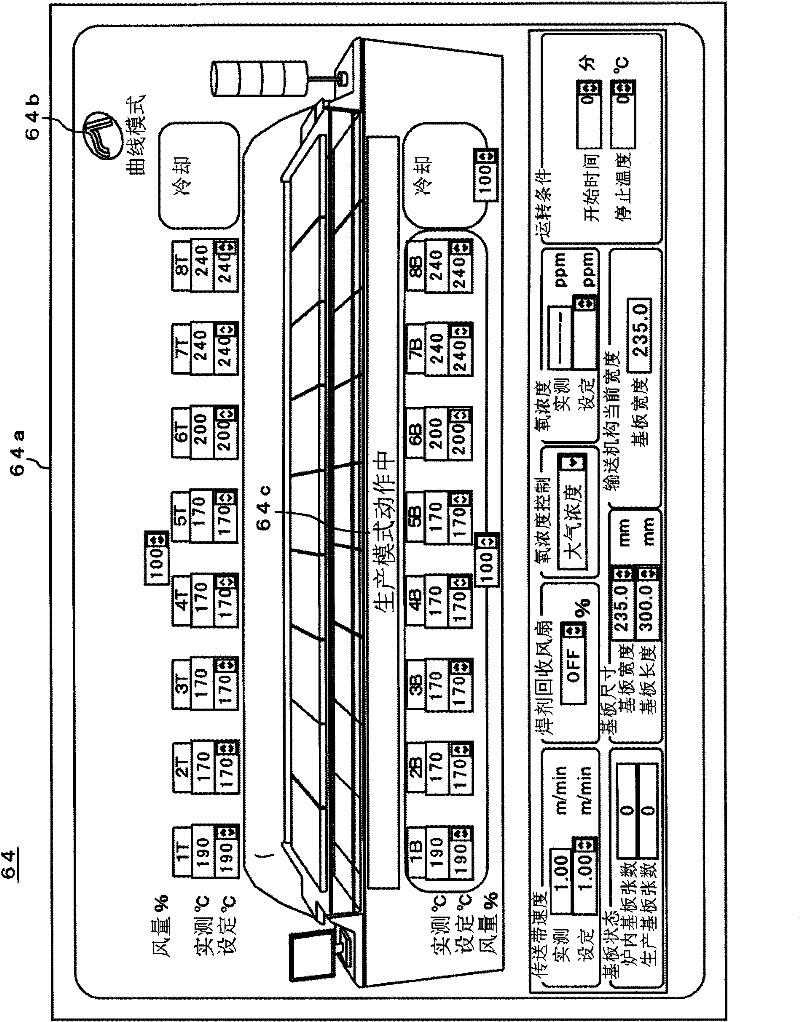

[0027] figure 1 It is a figure explaining an example of the structure of the reflow soldering apparatus 100 of this invention. The reflow soldering apparatus 100 of the present invention is characterized by having a production mode and a temperature profile mode. In the temperature profile mode, an alarm is generated before the substrate 30 transported in the main body of the reflow soldering apparatus reaches the output port 10b of the reflow soldering apparatus 100 sound.

[0028] Such as figure 1 As shown, the reflow soldering device 100 includes a reflow soldering device main body 10, a heater 12, a fan 14, a motor 16, a cooler 18, an inlet side sensor portion 20, an outlet side sensor portion 22, and a conveyor belt 34. The reflow soldering apparatus main body 10 is composed of a tunnel-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com