Combined mold for extra-large casting and forging

A combined mold and super-large technology, applied in the direction of casting mold, core, casting mold composition, etc., can solve the problems of unqualified casting and forging products, complex structure, difficult production, etc., to achieve easy mold removal, improve efficiency, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

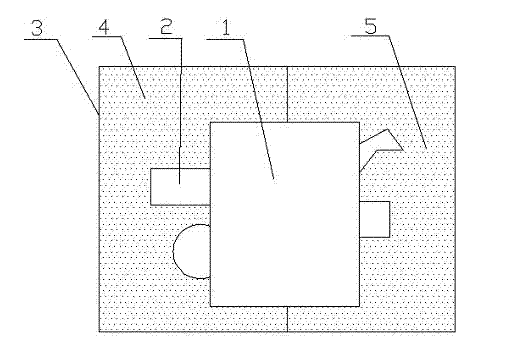

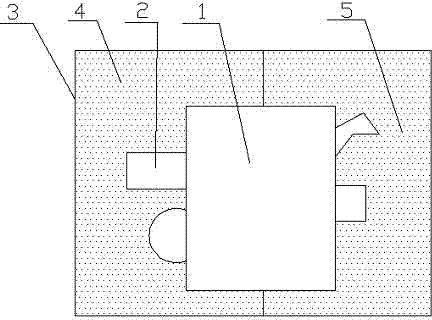

[0008] Such as figure 1 The super-large casting and forging combined mold shown in the figure has a regular-shaped wooden cylinder 1 as its main body, and additional parts are components of the required shape for super-large casting and forging made of lost foam 2. According to the size of the super-large workpiece to be cast and forged Shape, install the lost foam 2 on the main cylinder body 1, and then place the combined mold in an empty box 3 composed of left and right parts, first pour half of the resin sand into the left side of the combined mold in the box 3, After the resin 4 sand on the left side is finalized, the composite mold is drawn out, and then the resin sand is poured out of the right composite mold body of the box, and the composite mold is pulled out after the right side resin sand 5 is finalized, and then two matching resin sands are made. The shape of the composite mold composed of sand, and finally combine the shapes of the two composite molds together.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com