Precise motion platform with vibration dampers

A vibration damping device and precision motion technology, applied in the field of motion platforms, can solve problems such as high manufacturing cost and interference, and achieve the effects of reducing manufacturing costs, increasing degrees of freedom, and reducing manufacturing precision requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

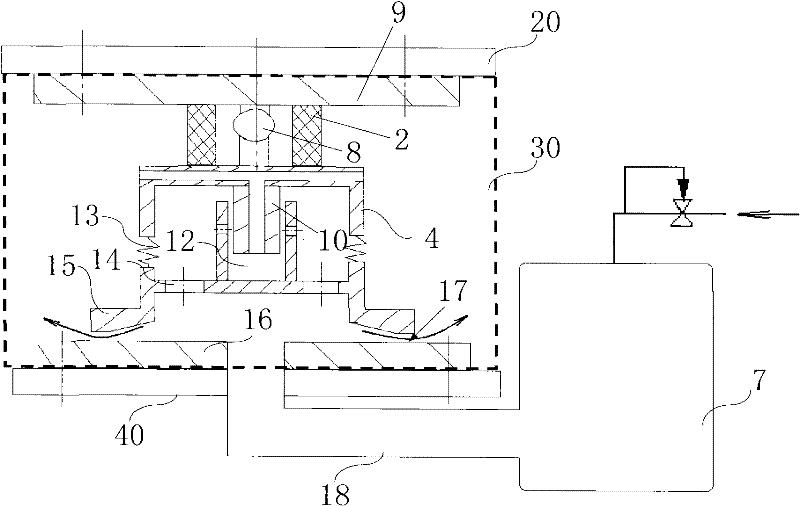

[0019] In order to better understand the technical content of the present invention, specific embodiments are given together with the attached drawings for description as follows.

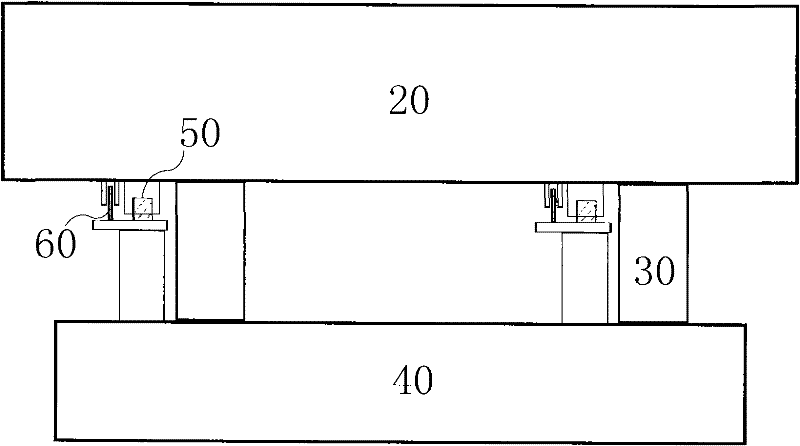

[0020] figure 1 Shown is a side-view structure schematic diagram of the precision motion platform of the present invention.

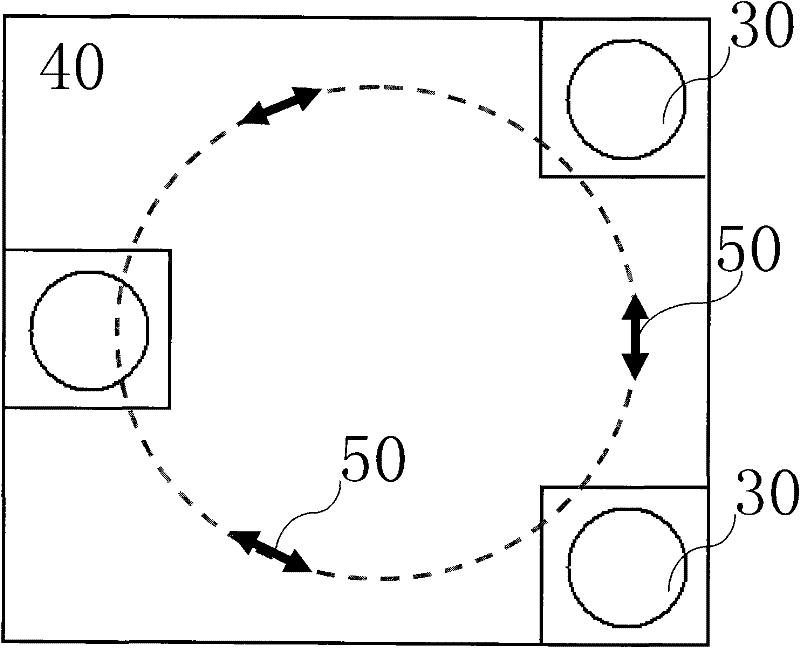

[0021] Such as figure 1 As shown, the precision motion platform includes a micro-motion table 20 , a base 40 , a vibration damping device 30 and a horizontal motor 50 . Base 40 supports the entire precision motion platform. The vibration-damping device 30 is placed between the base 40 and the micro-motion table 20 to play a role of vibration-damping. The vertical motor 60 and the horizontal motor 50 are placed between the base 40 and the micro-motion table 20 to drive the micro-motion table 20 to move vertically and horizontally. The horizontal motor 50 is used to actively control the position or speed of the micro-motion table 20 in the horizontal direction, and the ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com