Piston cylinder assembly

A piston cylinder and assembly technology, which is applied in the direction of fluid pressure actuation device, etc., can solve the problems of heavy weight of multi-stage piston cylinders, troubles for users, and breakage, so as to avoid damage and breakage of drill pipes and ensure stable and normal work , The effect of reducing the installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

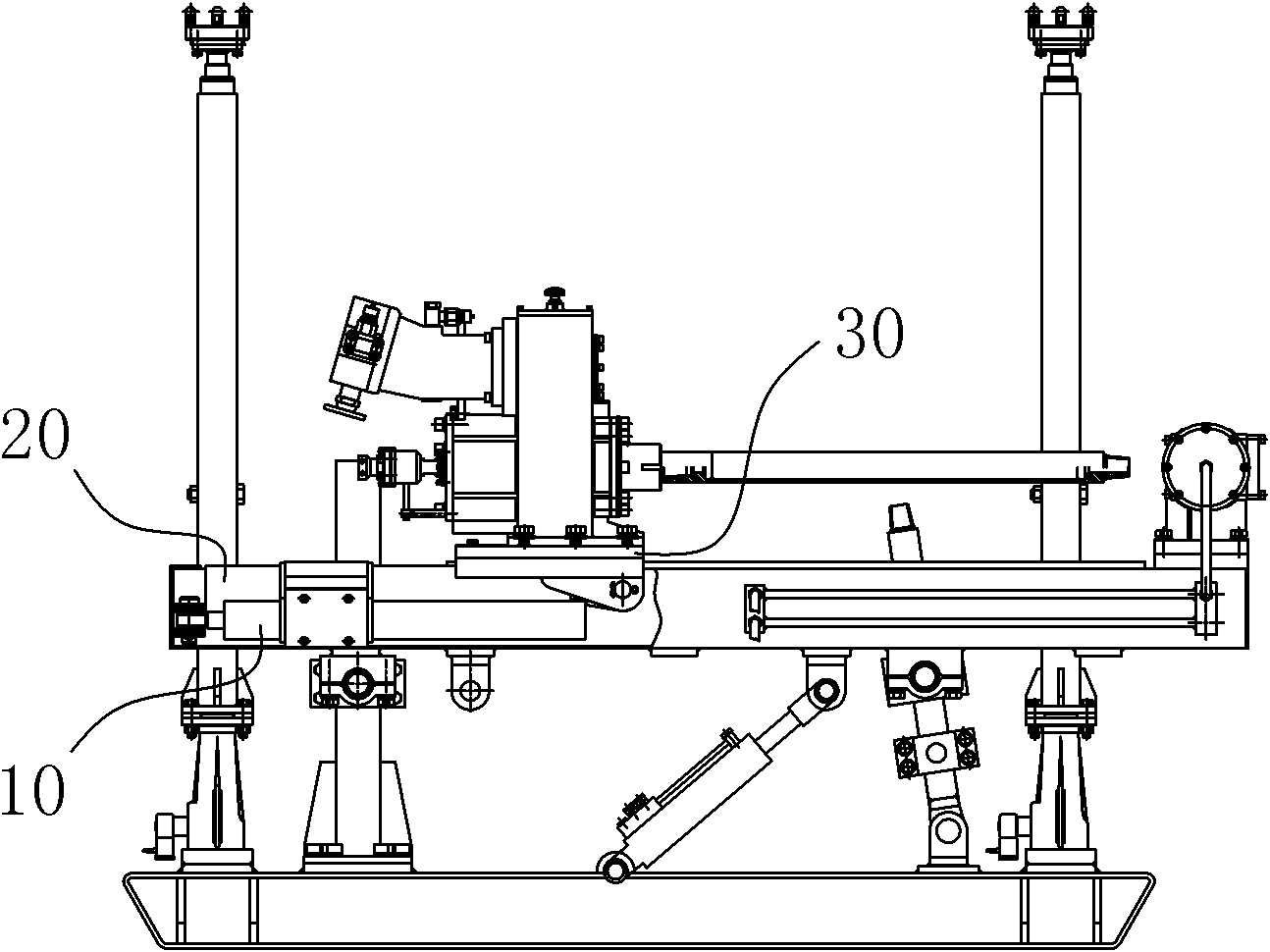

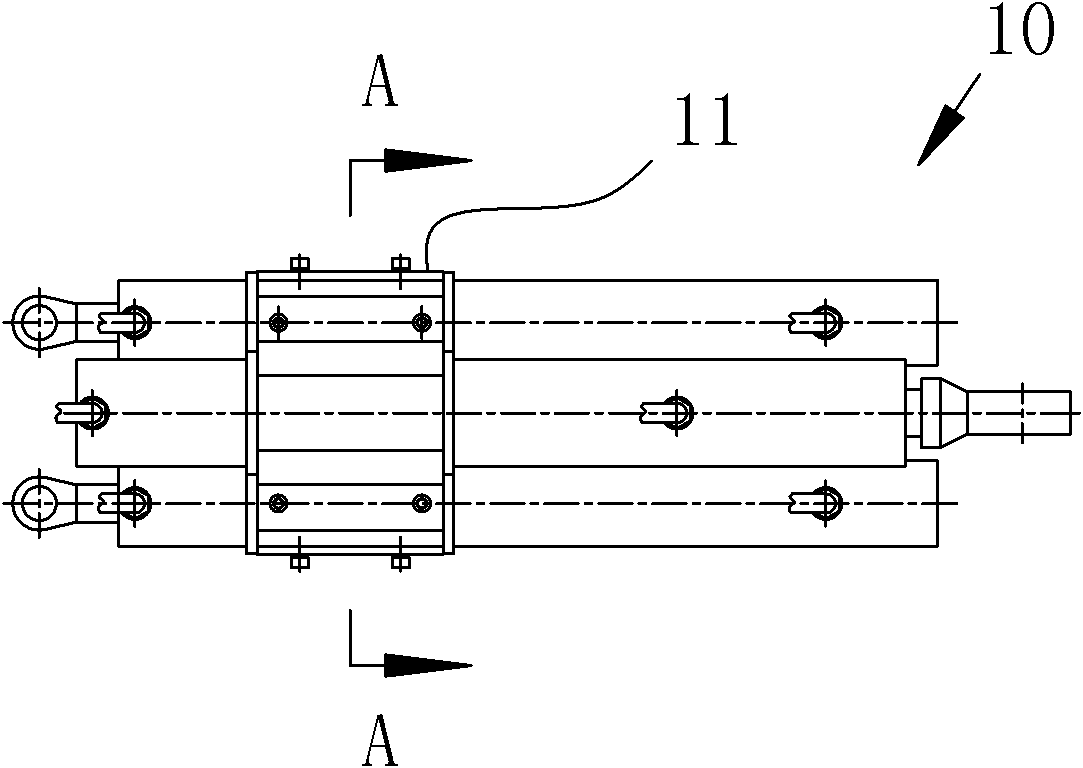

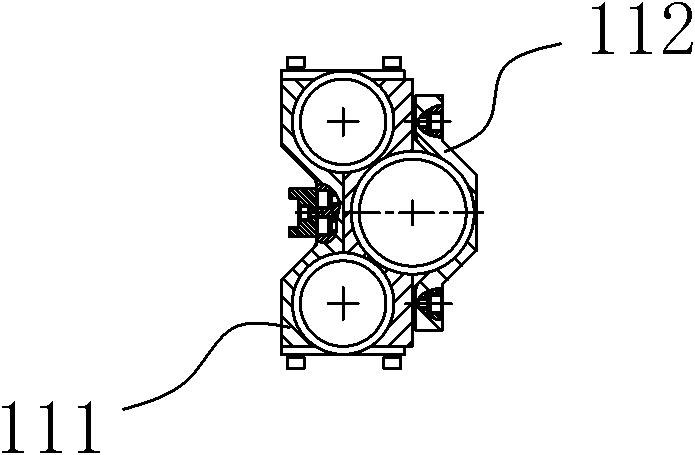

[0014] A piston-cylinder assembly, including a piston-cylinder unit 10, the piston-cylinder unit 10 is composed of three or more piston-cylinders in reverse and fixedly connected to each other, and the piston-cylinder units 10 are reversed to form The pushing or pulling forces are arranged symmetrically.

[0015] In the present invention, since the cylinder bodies of each layer of piston cylinders are fixed to each other and move in reverse, the stroke loss of the piston rod body itself is reduced, making its stroke larger than that of a single multi-stage piston cylinder, thereby making it Under the same stroke, the volume is smaller and the installation space is reduced. At the same time, the present invention can ensure uniform force application by reducing the number of stages of a single piston cylinder under the same stroke. At the same time, because the piston-cylinder units 10 are opposite to each other And the thrust or pulling force that forms are all symmetrically a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com