Electric ice raking machine

An ice raking and electric technology, which is applied in water conservancy projects, cleaning of open water surfaces, construction, etc., can solve problems such as poor work safety, poor water flow, and low labor efficiency, and achieve good ice removal effects, reasonable structure, reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is further described below in conjunction with embodiment and accompanying drawing.

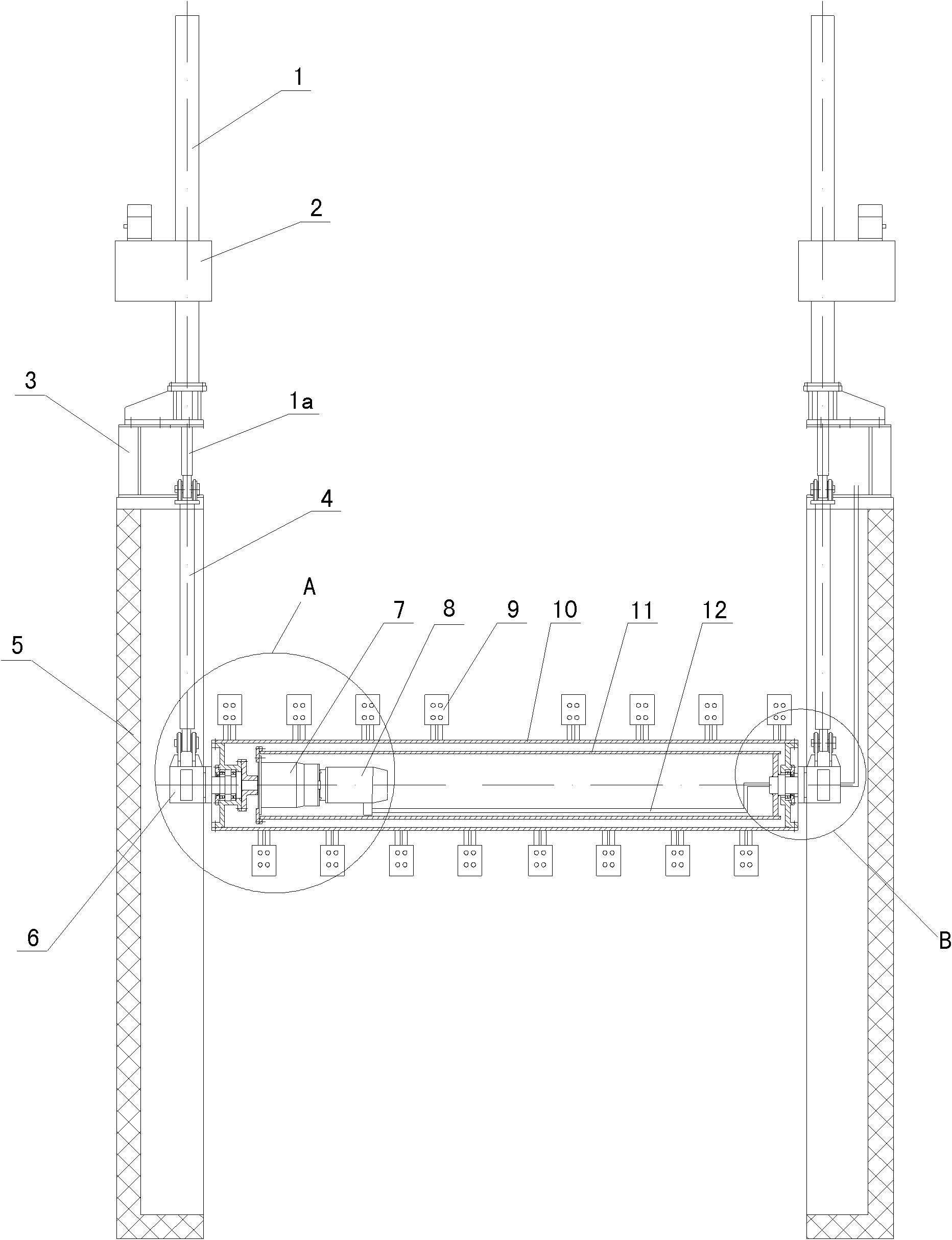

[0014] see figure 1

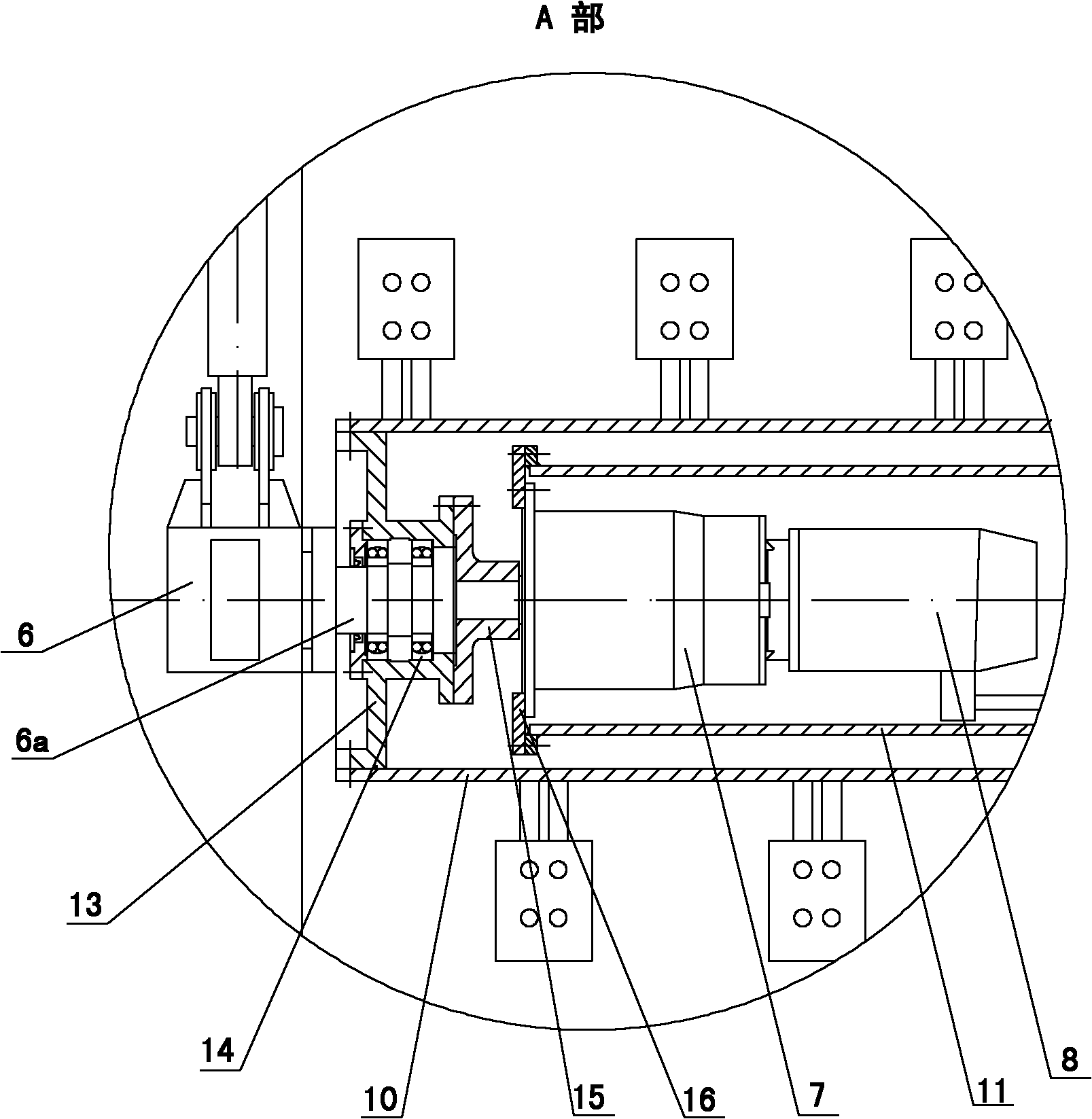

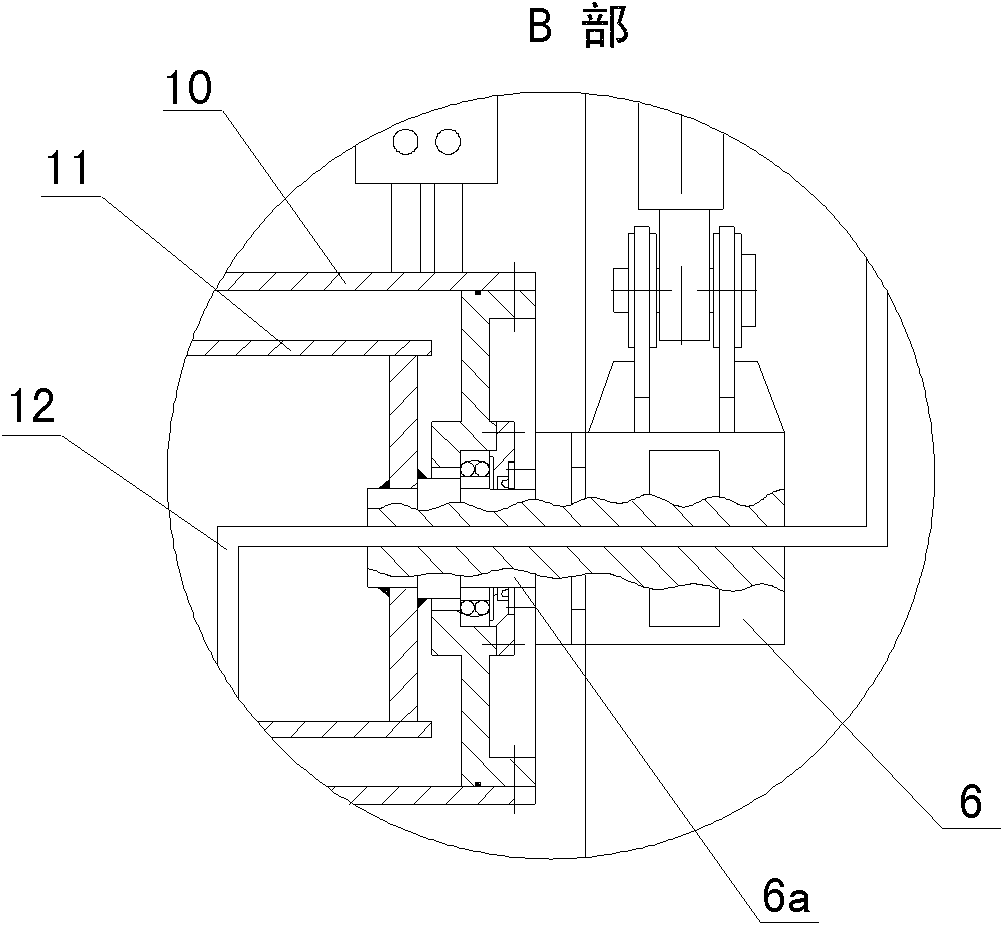

[0015] The electric ice raking machine provided by the present invention has a pair of vertical rails 5 arranged oppositely. On the support 3, the piston rod 1a of the hydraulic cylinder 1 is parallel to the track and the front end is downward, and the front end of each hydraulic cylinder piston rod 1a is hingedly connected with the upper end of the tie rod 4 in the corresponding track 5. The lower end of each pull rod 4 is connected with a bearing seat 6 in a hinged manner, and the two ends of a drum 10 located between a pair of rails 5 are supported by the bearing housing 6, and the two ends of the roller 10 and the bearing housing 6 are rotatable. Cooperate. There are more than two groups of rake teeth 9 arranged on the outer side of the drum 10. A motor 8 and a reducer 7 are arranged inside the drum 10. The rotating shaft of the motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com