Method for producing gas by oxygen enrichment and thermolysis of organic solid wastes

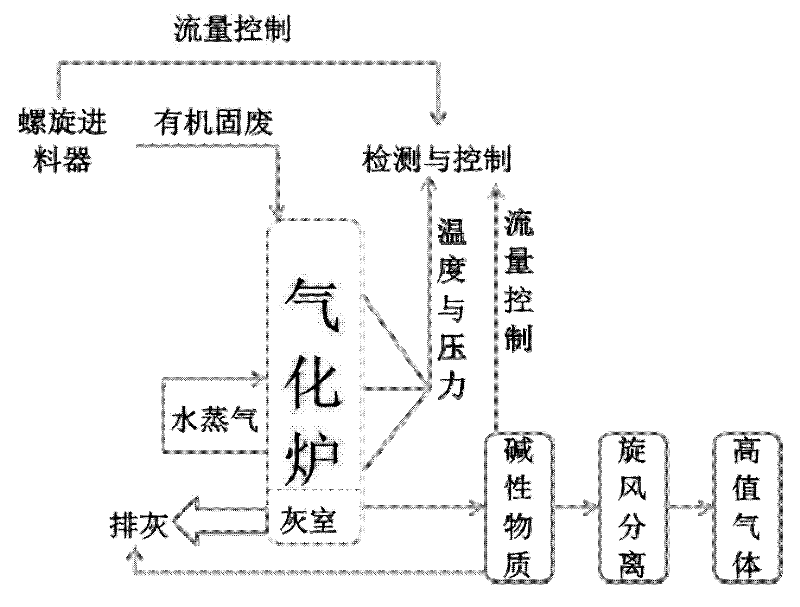

A technology for organic solids and wastes, which is applied in the manufacture of combustible gases, granular/powdered fuel gasification, bulk chemical production, etc. It can solve the problems of low waste utilization efficiency, reduce secondary pollution, improve quality, The effect of less nitrogen oxides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

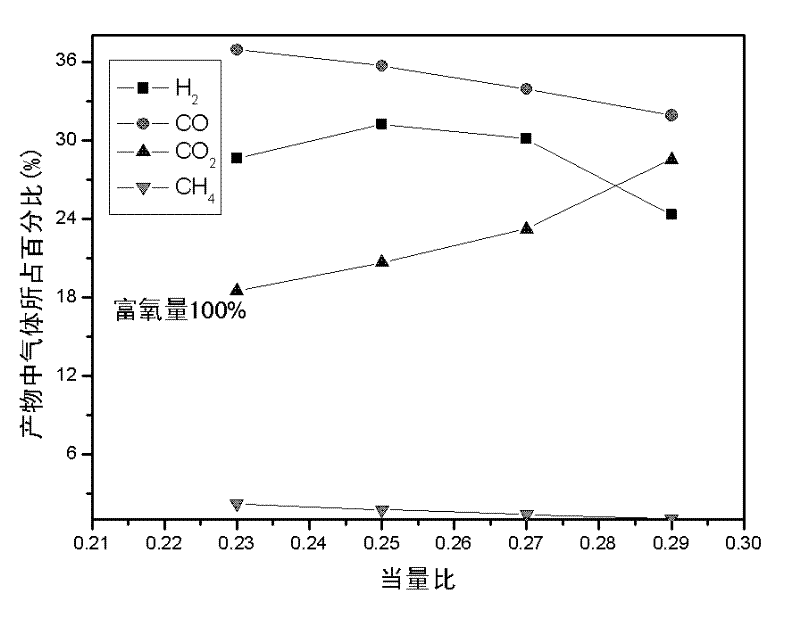

[0020] The following is combined with the implementation of the project (973 project of the Ministry of Science and Technology (2011CB201501); the 2010 Guangdong Province-Chinese Academy of Sciences comprehensive strategic cooperation project (2010A090100035); the important direction project of the Chinese Academy of Sciences Knowledge Innovation Project (KSCX2-EW-G-1-5)) The process is based on the data in the experimental process of the gasifier designed in the present invention and the specific implementation process to further describe the content of the present invention in detail.

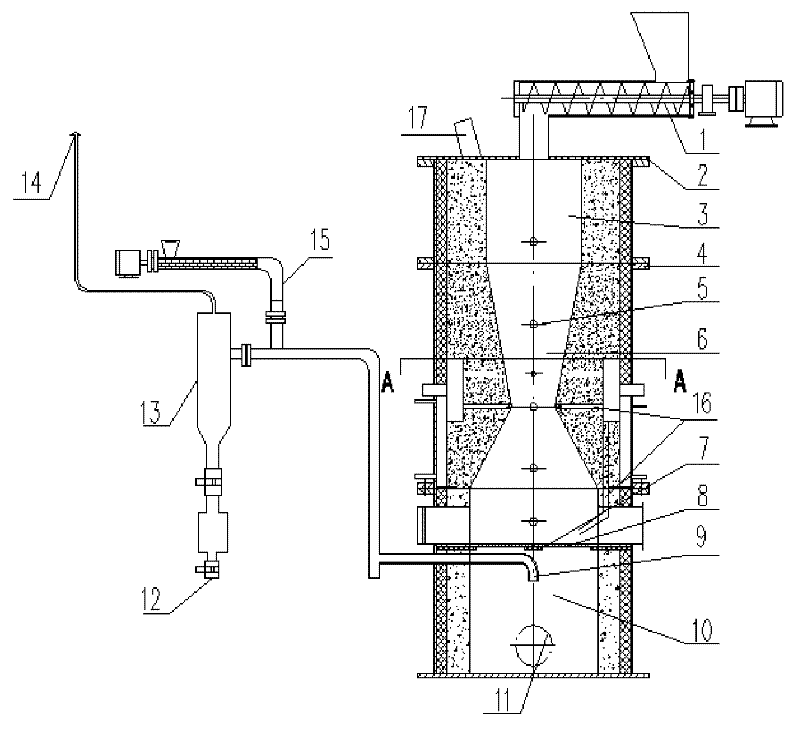

[0021] Such as figure 2 As shown, the equipment used in this embodiment is mainly composed of a screw feeding device 1, a cover plate 2, a drying section 3, a pyrolysis gasification section 6, a support block 7, a fire grate 8, a catalytic reduction section ash chamber 10, and a cyclone dust collector 13 , alkaline spray chamber 15 and other devices to form a complete set of oxygen-enriched ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com