Bead string rope uniform tensioning device with combined hydraulic cylinder

A technology of tensioning device and hydraulic cylinder, which is applied in the direction of manufacturing tools, working accessories, stone processing equipment, etc., to achieve the effect of balanced tension and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

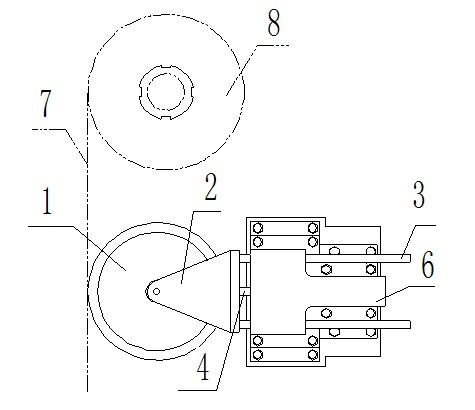

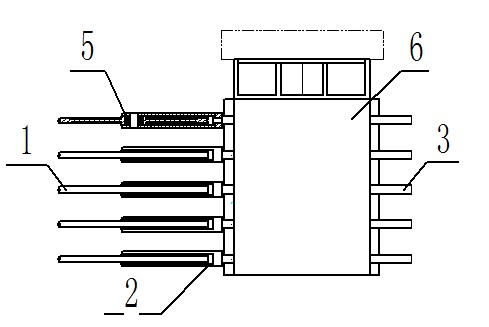

[0012] Such as figure 1 with figure 2 As shown, the combined hydraulic cylinder beaded rope uniform tensioning device of the present invention includes a combined hydraulic cylinder 6, a supporting frame 2, a tensioning wheel 1, and a guide rod 3. The combined hydraulic cylinder 6 has more than two hydraulic chambers, and each hydraulic chamber shares an oil inlet and an oil return port. There is a piston rod 4 in one hydraulic chamber, and the extension ends of each piston rod 4 are connected to a support Each support frame 2 is equipped with a tensioning wheel 1 through a bearing 5, and each support frame 2 is provided with two guide rods 3, and the guide rods 3 are sleeved in the combined hydraulic cylinder 6.

[0013] When in use, the combined hydraulic cylinder 6 is installed on the feed pallet of the multi-rope diamond bead saw, and the tension wheel 1 rotates under the drive of the rope pulley 8 and the bead cord 7 of the multi-rope diamond bead saw. 6 Supply hydraulic o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com