Electret electrode, actuator using the electret electrode, oscillation generator, oscillation generation device, and communication device using the oscillation generation device

A technology of vibration power generation and electret, which is applied to electret electrostatic transducers, electrostatic generators/motors, electrets, etc., can solve problems such as cracked substrates, low surface potential, and low power generation efficiency, and achieve Stable output voltage, reduced maintenance times, and improved power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

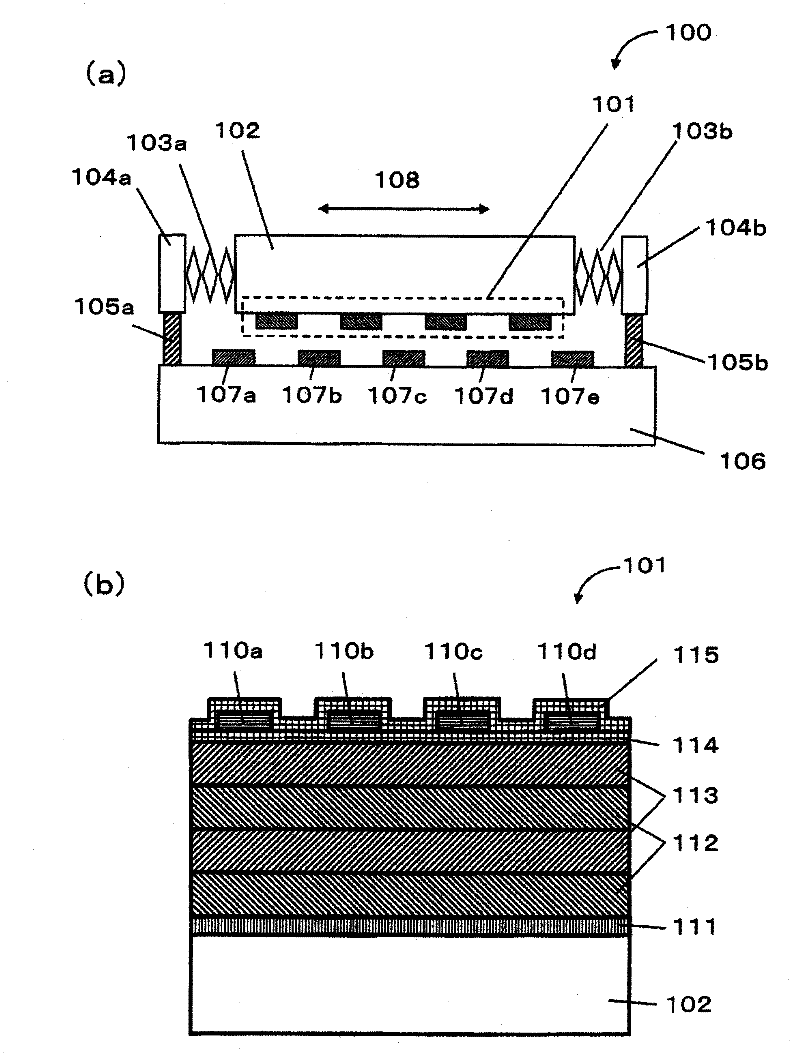

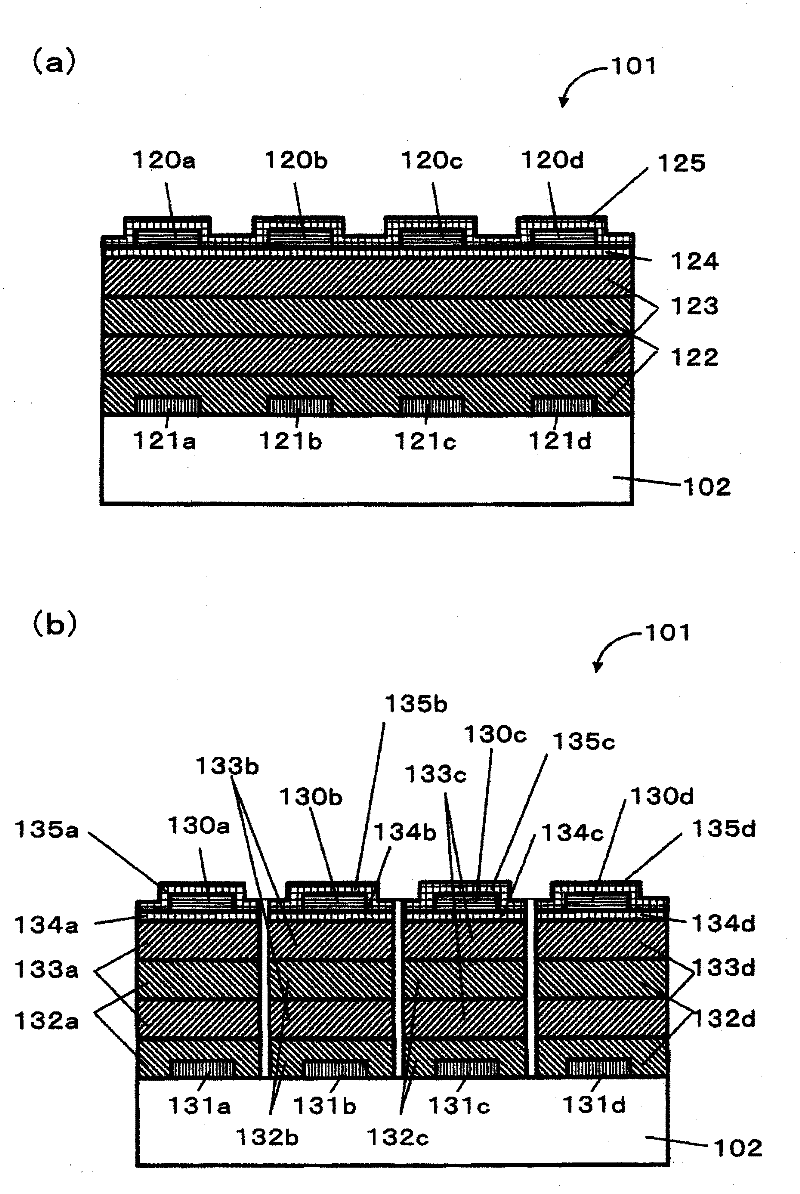

[0043] figure 1 The vibration power generator in Embodiment 1 of the present invention is shown, (a) is a cross-sectional view of the vibration power generator 100 , and (b) is an enlarged cross-sectional view of the electret electrode part 101 .

[0044] figure 1 In (a), the vibration power generator 100 has: a first substrate 102 including an electret electrode portion 101; elastic structures 103a, 103b connecting the first substrate 102 to fixing structures 104a, 104b; and a second substrate 106 . The fixed structures 104a, 104b are connected to the second substrate 106 via the supports 105a, 105b. On the second substrate 106, electrodes 107a, 107b, 107c, 107d, and 107e are formed.

[0045] exist figure 1 In (b), the electret electrode portion 101 includes a first substrate 102 and a conductive film 111 formed on the first substrate. On the conductive film 111, the first insulating film 112 and the second insulating film 113 are laminated alternately to form a four-...

Embodiment approach 2

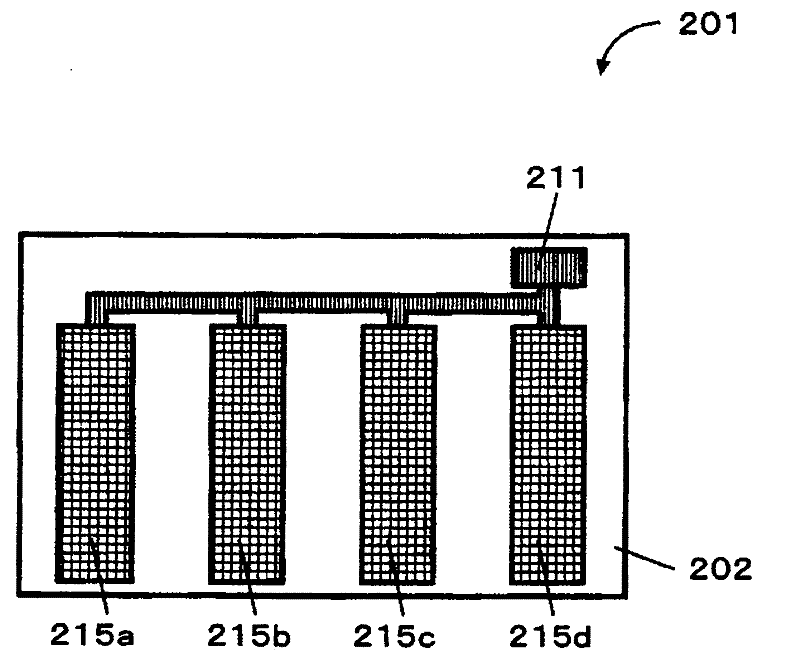

[0079] image 3 It is a top view of the electret electrode part in Embodiment 1 of this invention.

[0080] exist image 3 Among them, the electret electrode portion 201 is composed of a conductive film 211 , a second insulating film 215 ( 215 a , 215 b , 215 c , and 215 d ), and a substrate 202 . The section of the electret electrode part 201 is, for example, the same as figure 2 The section shown in (b) is the same.

[0081] In Embodiment 2, the conductive film 211 serves as a counter electrode for the charges held in the electret film 130 in the electret electrode portion 201 , and the conductive film 211 is electrically connected to the GND terminal, for example. With such a configuration, the surface potential of the surface of the electret film is fixed, and an AC signal centered on GND can be output in the power generator. Therefore, the electret electrode of this constitution can be used advantageously. exist image 3 Among them, the electret may be, for example...

Embodiment approach 3

[0088] As Embodiment 3 of the present invention, a vibration power generator will be described. Figure 4 is a block diagram of the vibration power generation device 300 . exist Figure 4 Among them, the vibration power generator is the vibration power generator described in Embodiment 1 or Embodiment 2.

[0089] exist Figure 4 Among them, the vibration power generation device 300 includes: a vibration power generator 301 , a rectification circuit 302 , a voltage conversion circuit 303 , an output switching circuit 304 , an electric storage circuit 305 and a voltage control circuit 306 . The AC voltage output from the vibration generator 301 is converted into a DC voltage by the rectifier circuit 302 . The DC voltage is input to the voltage conversion circuit 303 and is subjected to voltage conversion until it becomes the output voltage level of the vibration power generating device 300 . The converted voltage is input to the voltage control circuit 306 or the power stora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com