Fill-level measuring device

A material level measurement and material technology, applied in the field of material level measuring instruments, can solve the problems of increased power loss, strong input reflection of electromagnetic signals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

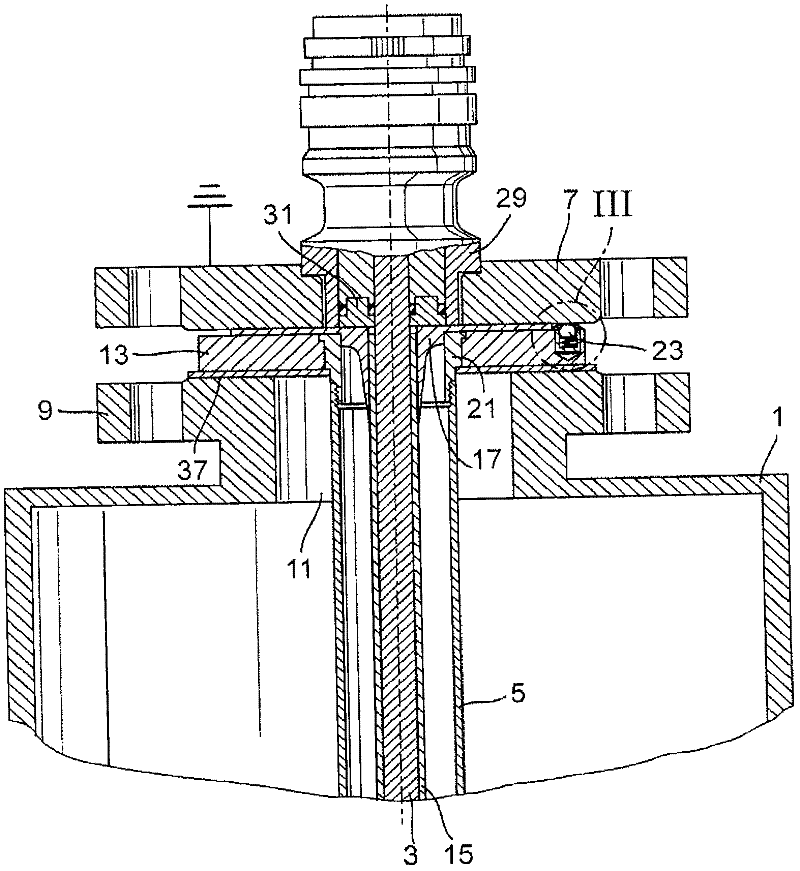

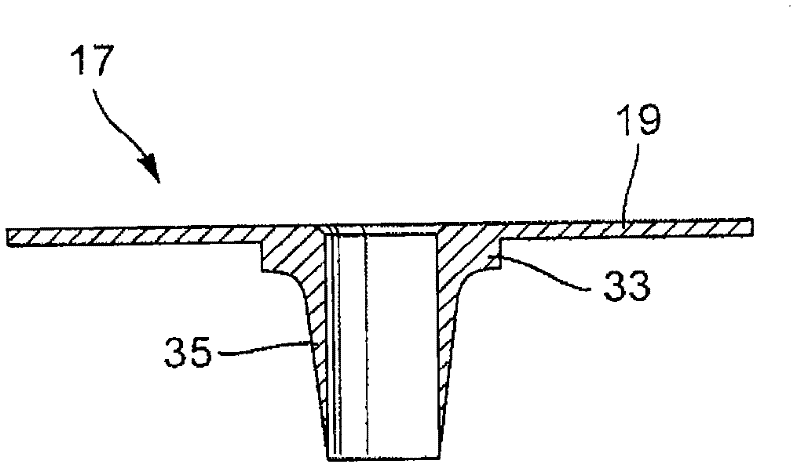

[0035] figure 1 A partially cutaway view of a filling level measuring device according to the invention is shown. The fill level measuring device is used for capacitive fill level measurement and / or for fill level measurement according to the transit time principle of the filling material in the container 1 . For this purpose, the filling level measuring device has a coaxial measuring probe which comprises an inner conductor 3 and a shielding conductor 5 coaxially surrounding the inner conductor 3 .

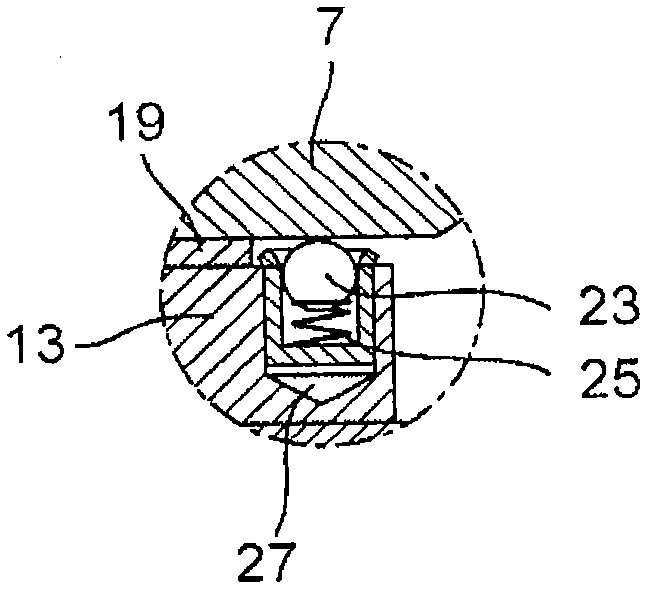

[0036] The filling level measuring device has a fastening device 7 with which the measuring device can be mounted on a container opening 11 which is equipped with a counterpart 9 corresponding to the fastening device 7 . In the illustrated embodiment, the fixing means 7 is a flange and the counter piece 9 is a correspondingly shaped counter flange. It goes without saying that other fastening devices known to those skilled in the art and their corresponding counterparts can also...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com