Electric gate valve for smoke exhaust frame of anode roasting furnace

A technology of anode roasting furnace and smoke exhaust rack, which is applied in furnaces, furnace components, waste heat treatment and other directions, can solve the problems of scrapping and inoperability of regulating valves, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

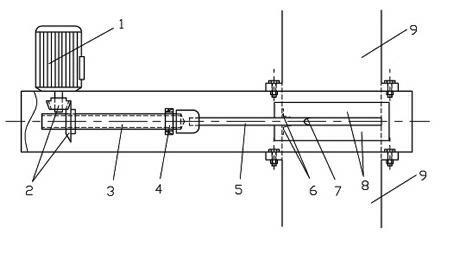

[0014] combine figure 1 with figure 2 As shown, the anode roaster smoke exhaust rack electric gate valve in the present embodiment mainly includes the following four parts:

[0015] 1. Electric mechanism

[0016] The electric mechanism is composed of a motor 1, a transmission part 2 (that is, a pair of bevel gears), an electric push rod 3, and a linear motion bearing 4. The motor 1 rotates, and the electric push rod 3 is driven forward and reverse through the transmission part 2 . The electric push rod 3 moves back and forth in the linear motion bearing 4, and pushes the plate 5 to move back and forth, thereby adjusting the opening of the smoke exhaust port. The plugboard is inserted into the exhaust port, so the regulating valve is called a plugboard valve.

[0017] 2. Up and down scraper

[0018] The upper and lower scrapers 6 are fixed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com