Online repair method for asbestos type expansion joint of pipeline

A repair method and technology of expansion joints, which are applied in the direction of pipe components, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems of reduced sealing performance of pipelines, pipeline stoppage, failure to replace new expansion joints, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

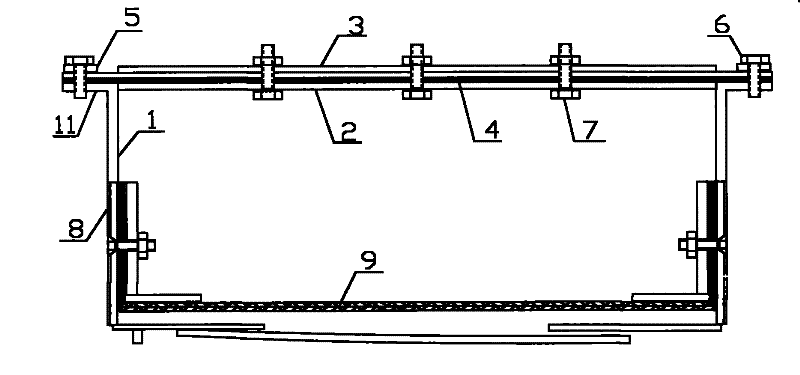

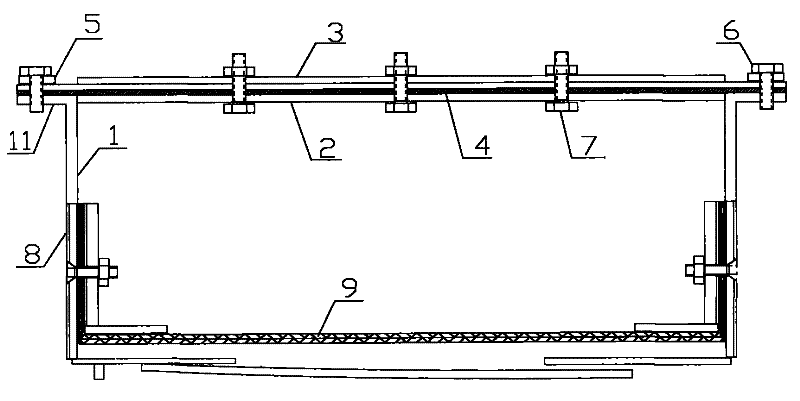

[0013] like figure 1 As shown, the diagram is a schematic diagram of the upper part of the expansion joint after longitudinal sectioning. The online repair method for the asbestos-type expansion joint of the pipeline of the present invention includes two flanges 8 connecting the two ends of the asbestos-type expansion joint 9. The method includes the following steps:

[0014] Step 1, making two support plates 1, the center of the support plate 1 has a through hole matching the outer ring of the flange plate 8, the outer ring of the support plate 1 is provided with a shoulder 11, and the support plate shoulder The parts 11 extend outward respectively and are vertically provided with screw holes, and the central through holes of the two support plates 1 are respectively welded to the outer rings of the two flange plates 8;

[0015] Step 2. Weld the first pressure plate 2 between the tops of the two support plates 1, the first pressure plate 2 has several screw holes at intervals...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com