A detection method for sticking mold failure of press

A fault detection and detection method technology, applied in forging/pressing/hammering machinery, measuring devices, forging/pressing/hammer devices, etc., can solve problems such as inability to demould, fail to find out the fault point, and low production efficiency. Achieve the effect of reducing production failure time, reducing labor intensity of workers, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0027] The following discusses specific embodiments:

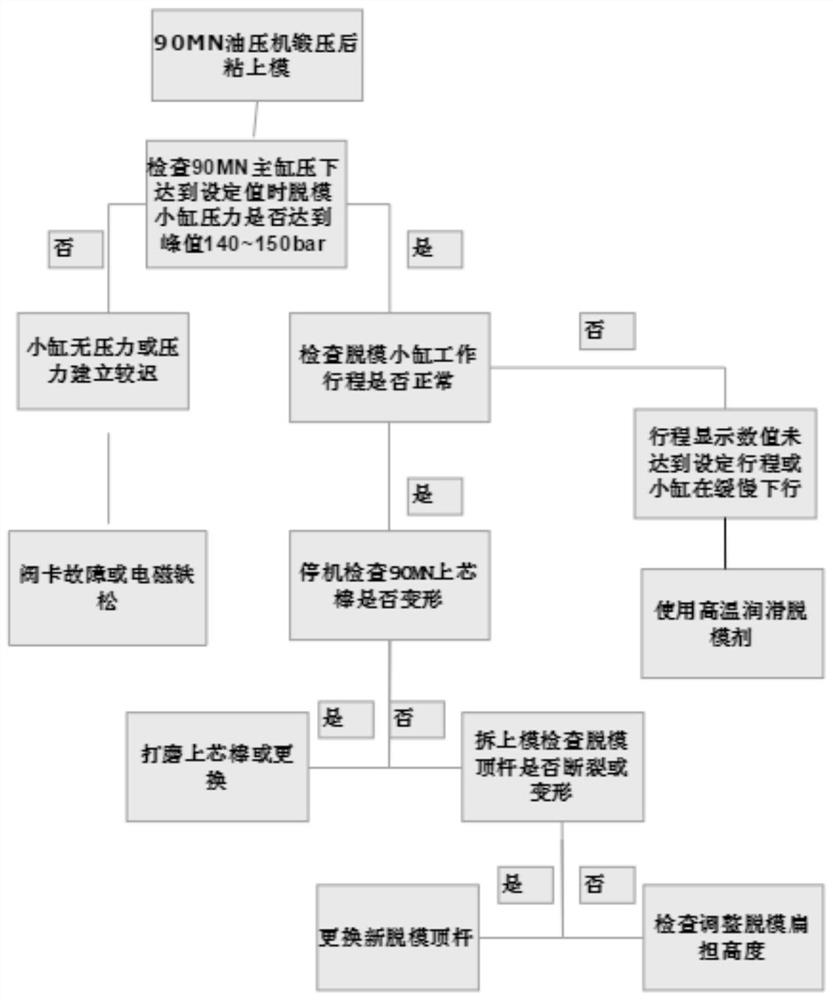

[0028] The present invention discloses a detection method for a mold sticking failure of a press. The press includes a press mold, and the press is used for forging and forming train wheels; when the forged wheel cannot be normally demoulded on the press mold:

[0029] Described detection method comprises the steps:

[0030] Step 1: Observe whether the pressure of the small demoulding cylinder displayed on the monitoring interface is normal. The pressure here refers to the pushing pressure of the small demoulding cylinder on the red steel wheel; Repair; if the pressure is normal, proceed to the next step;

[0031] Step 2: The pressure and establishment time of the demoulding small cylinder are normal; the establishment time here refers to the time required for the equipment main cylinder to drive the upper die up to set the distance after the red steel forging is completed; when the establishment time is short, it means t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com