Twelve-strand rope sleeve and manufacturing method thereof

A production method and rope technology, which is applied in the field of ropes, can solve the problems of short service life of rope sleeves, weak insertion ends, easy to pull open and loose, etc., and achieve the effects of beautiful appearance, improved structural integrity, and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

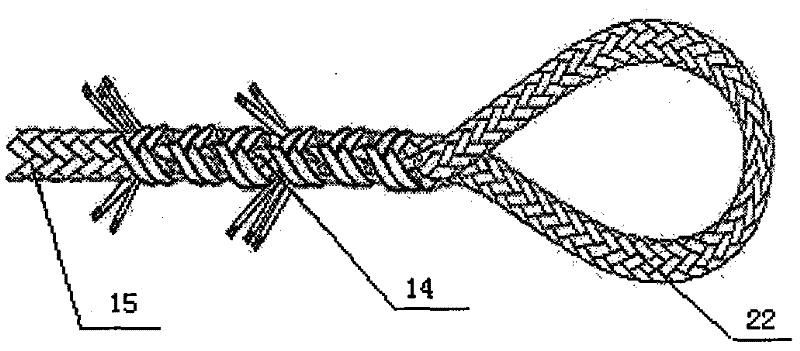

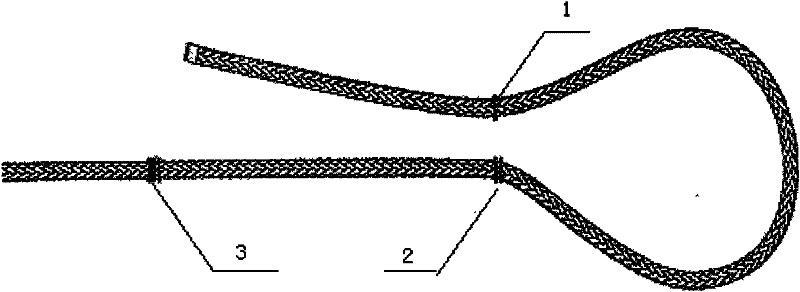

[0033] Embodiment one: get a twelve-strand synthetic fiber rope, measure the diameter, then use one end as the starting end 4, and measure the length from the starting end to be 31.5 times the diameter and make a mark 1, then make it according to the desired The circumference of the ferrule 22, set aside the corresponding length, and mark it as mark two 2, measure the length of 36.75 times the diameter from mark two 2 and record it as mark three 3, such as figure 1 shown. From mark 1, pull out six braided rope strands towards the starting end 4, Z means twisting counterclockwise, S means twisting clockwise, and the six braided rope strands are Z twisted to strand 5, S twisted To strand 6, Z is twisted to strand 7, S is twisted to strand 51, Z is twisted to strand 61, S is twisted to strand 71, such as figure 2 and image 3 shown. Insert the remaining six rope strands 99 (respectively Z, S, Z, S, Z, S) into the rope from the mark two 2 with the traction iron pin 88, draw th...

Embodiment 2

[0036] Embodiment two: get a twelve-strand ultra-high molecular weight polyethylene fiber rope, measure the diameter, then use one end as the starting end 4, and measure the length from the starting end to be 30 times the diameter and make a mark-1, Then according to the perimeter of the ferrule 22 to be made, set aside the corresponding length, which is marked as mark two 2, and the length of 35 times the diameter is measured from mark two 2 and marked as mark three 3, as figure 1 shown. From mark 1, pull out six braided rope strands towards the starting end 4, Z means twisting counterclockwise, S means twisting clockwise, and the six braided rope strands are Z twisted to strand 5, S twisted To strand 6, Z is twisted to strand 7, S is twisted to strand 51, Z is twisted to strand 61, S is twisted to strand 71, such as figure 2 and image 3 shown. Insert the remaining six rope strands 99 (respectively Z, S, Z, S, Z, S) into the rope from the mark two 2 with the traction iro...

Embodiment 3

[0040] Take a twelve-strand synthetic fiber rope, measure the diameter, then use one end as the starting end 4, and measure the length from the starting end to be 32 times the diameter and mark 1, then according to the ferrule 22 to be made The circumference of , set aside the corresponding length, record it as mark 2 2, measure the length 37 times the diameter from mark 2 2 and record it as mark 3 3, such as figure 1 shown. From mark 1, pull out six braided rope strands towards the starting end 4, Z means twisting counterclockwise, S means twisting clockwise, and the six braided rope strands are Z twisted to strand 5, S twisted To strand 6, Z is twisted to strand 7, S is twisted to strand 51, Z is twisted to strand 61, S is twisted to strand 71, such as figure 2 and image 3 shown. Insert the remaining six rope strands 99 (respectively Z, S, Z, S, Z, S) into the rope from the mark two 2 with the traction iron pin 88, draw the traction iron pin 88 from the mark three 3, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com