Method for rapidly cooling reaction product of oxygen-containing compound produced alkene

A technology for producing olefins from reaction products, which is applied in the direction of producing hydrocarbons from oxygen-containing organic compounds, ethylene production, and biological raw materials. Scale, avoid equipment blockage, improve the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

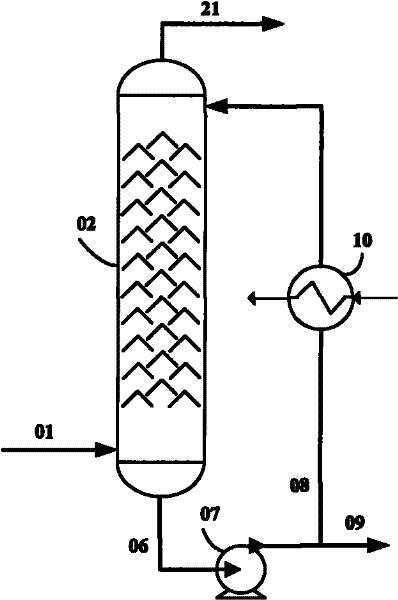

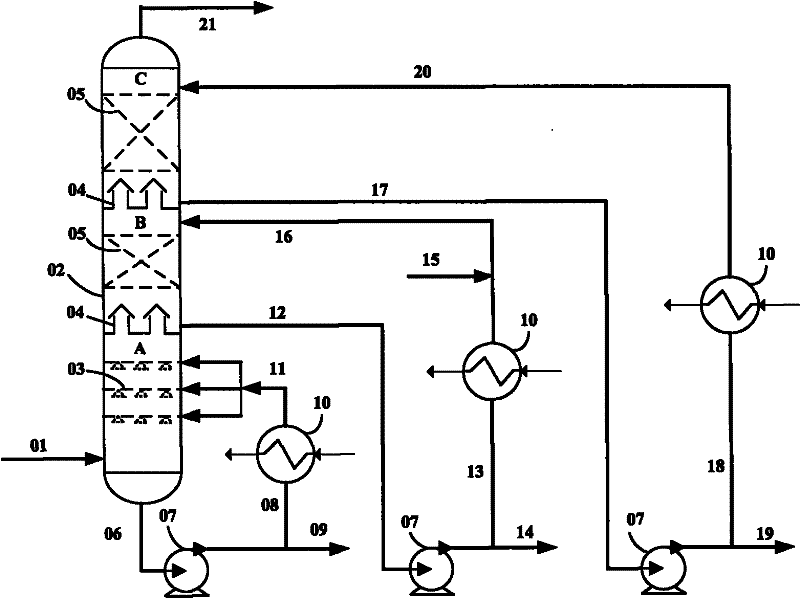

Embodiment 1

[0035] The reaction product feed composition (weight %) is: ethylene 15.0%, propylene 15.0%, water 60.5%, catalyst fine powder 2.0%, organic acid 200ppm, oxygen-containing compound 0.3%, other 7.2%, feed temperature 230 ℃. use figure 2 In the process flow shown, the number of spray layers in the lower section is 3, the installation angle α of the nozzles is 15°, and the arrangement of concentric circles is adopted. The theoretical number of towers for the middle packing is 2, and the theoretical number of towers for the upper packing is 5. The pressure of the quenching tower is 0.13MPag, and the lower section is quenched to 110°C (subcooling is about 10°C). After the tank liquid is withdrawn, 80% by weight of the catalyst is removed by liquid-solid separation equipment, and the ratio of circulating tank liquid volume / feed volume is 1 : 5; middle stage lye concentration is NaOH 8% by weight, and the ratio of circulating lye amount / feed amount is 1: 2, and the middle section te...

Embodiment 2

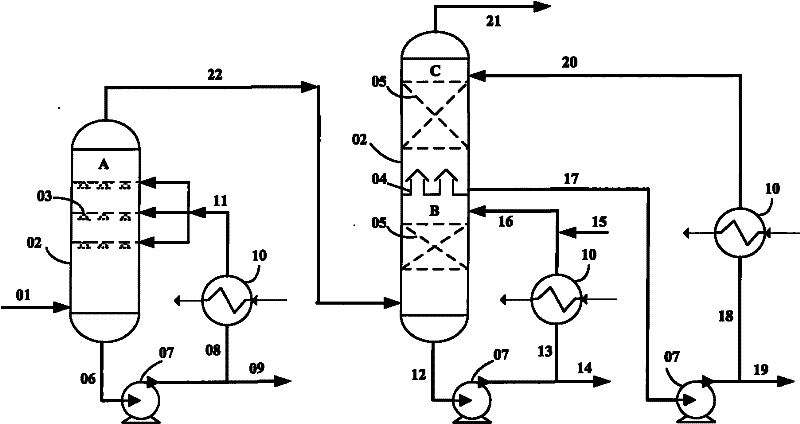

[0039] The reaction product feed composition (weight %) is: ethylene 15.0%, propylene 15.0%, water 60.5%, catalyst fine powder 2.0%, organic acid 200ppm, oxygen-containing compound 0.3%, other 7.2%, feed temperature 230 ℃. use image 3 In the process flow shown, the number of spraying layers in the lower section is 3, the installation angle α of the nozzles is 15°, and the arrangement of concentric circles is adopted. The pressure of the first quench tower is 0.14MPag, and the temperature at the top of the tower is 110°C (subcooling is about 10°C ), remove 80% by weight of the catalyst through liquid-solid separation equipment after the still liquid is extracted, and the ratio of circulating still liquid amount / feed amount is 1:5. The theoretical number of towers of the filler in the lower section of the second quenching tower is 2, the theoretical tower number of the filler in the upper section is 5, the concentration of the NaOH lye in the lower section is 8% by weight, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com