Jaw crusher with double shafts and double crank and rocker mechanisms

A technology of crank rocker and rocker mechanism, applied in grain processing and other directions, can solve the problems of incompatibility between work and discharge, and achieve the effects of easy adjustment, enhanced crushing capacity, and improved crushing ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

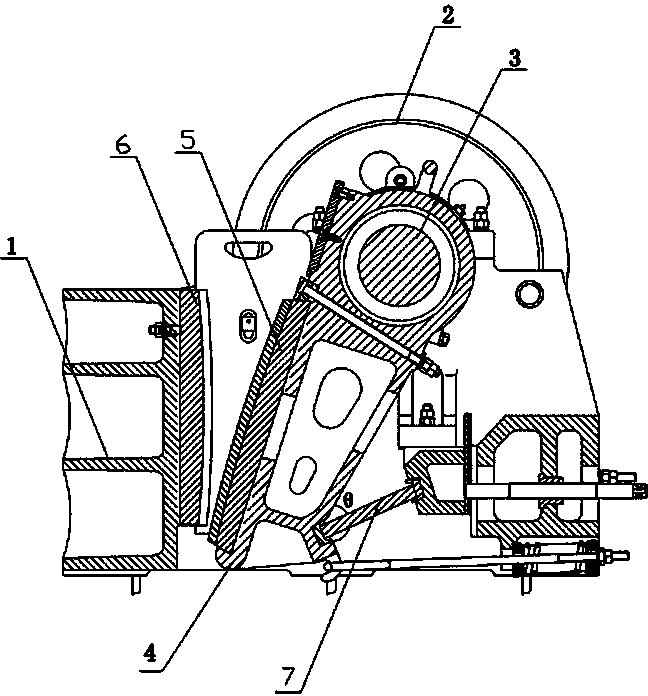

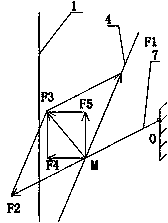

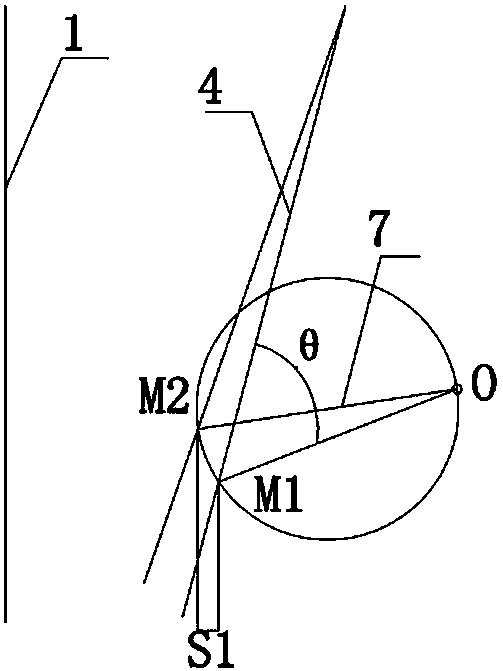

[0029] Example: such as figure 1 As shown, a jaw crusher with a double-shaft double-crank rocker mechanism includes a frame 1, a fixed jaw plate 6, a movable jaw plate 5, a front crank-rocker mechanism, a rear crank-rocker mechanism, and a transmission wheel. Wheel comprises front transmission gear 2 and rear transmission gear 13, and front transmission gear 2 and rear transmission gear 13 are meshed.

[0030] The front crank-rocker mechanism includes the front movable jaw 4, the front toggle plate 7 and the front eccentric drive shaft 3; the rear crank-rocker mechanism includes the rear movable jaw 8, the rear toggle plate 9 and the rear eccentric drive shaft 14; the front and rear movable jaws 4 , 8 are respectively pivoted on the front and rear eccentric drive shafts 3,14, the front eccentric drive shaft 3 is connected with the front transmission gear 2, and the rear eccentric drive shaft 14 is connected with the rear transmission gear 13. One end of the front toggle plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com