FischerTropsch synthesis slurry bed reactor

A technology of Fischer-Tropsch synthesis and slurry bed, which is applied in the field of chemical engineering, can solve the problems of low space utilization efficiency and small scale of reactors, and achieve the effects of improving space utilization, ensuring uniformity, and increasing space velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

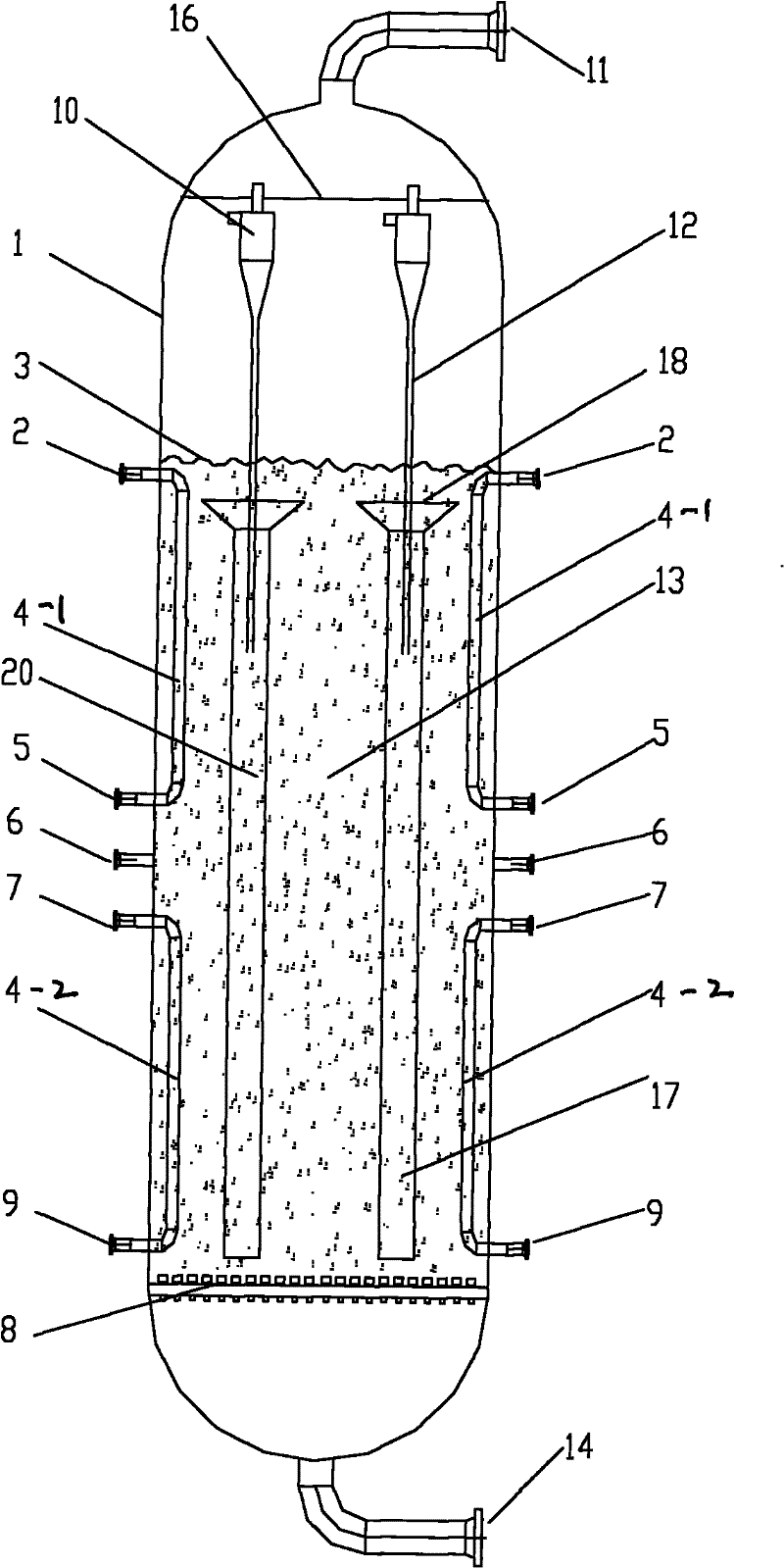

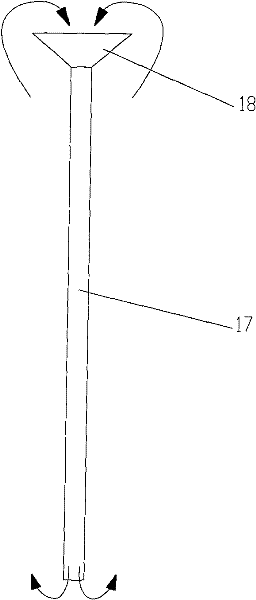

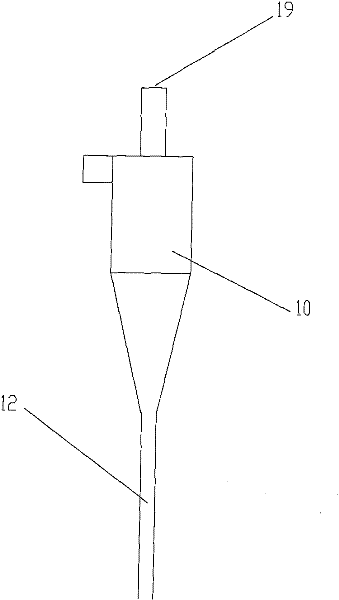

[0048] Such as figure 1Shown, the Fischer-Tropsch synthesis slurry bed reactor shell internal diameter of the present invention is 8 meters, and the reactor tangent height is 43 meters, arranges 7 circulating cups 20 such as Figure 5 , seven gas-liquid cyclones 10 are arranged on the top of the reactor. The normal slurry bed material level is located 32 meters above the syngas distribution plate, and the minimum material level height is 28 meters. The expansion port at the top of the circulation cup is located at a height of 27.5 meters, and the bottom of the feeding pipe of the circulation cup is located at a height of 0.3 to 0.6 meters above the syngas distribution plate.

[0049] During normal operation, the synthesis gas heated to 230-250°C is mainly composed of carbon monoxide and hydrogen, and enters the reactor from the synthesis gas inlet 14 at the bottom of the reactor at a pressure of 1.5-3.5 MPag, and is evenly distributed to the reactor through the synthesis gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com