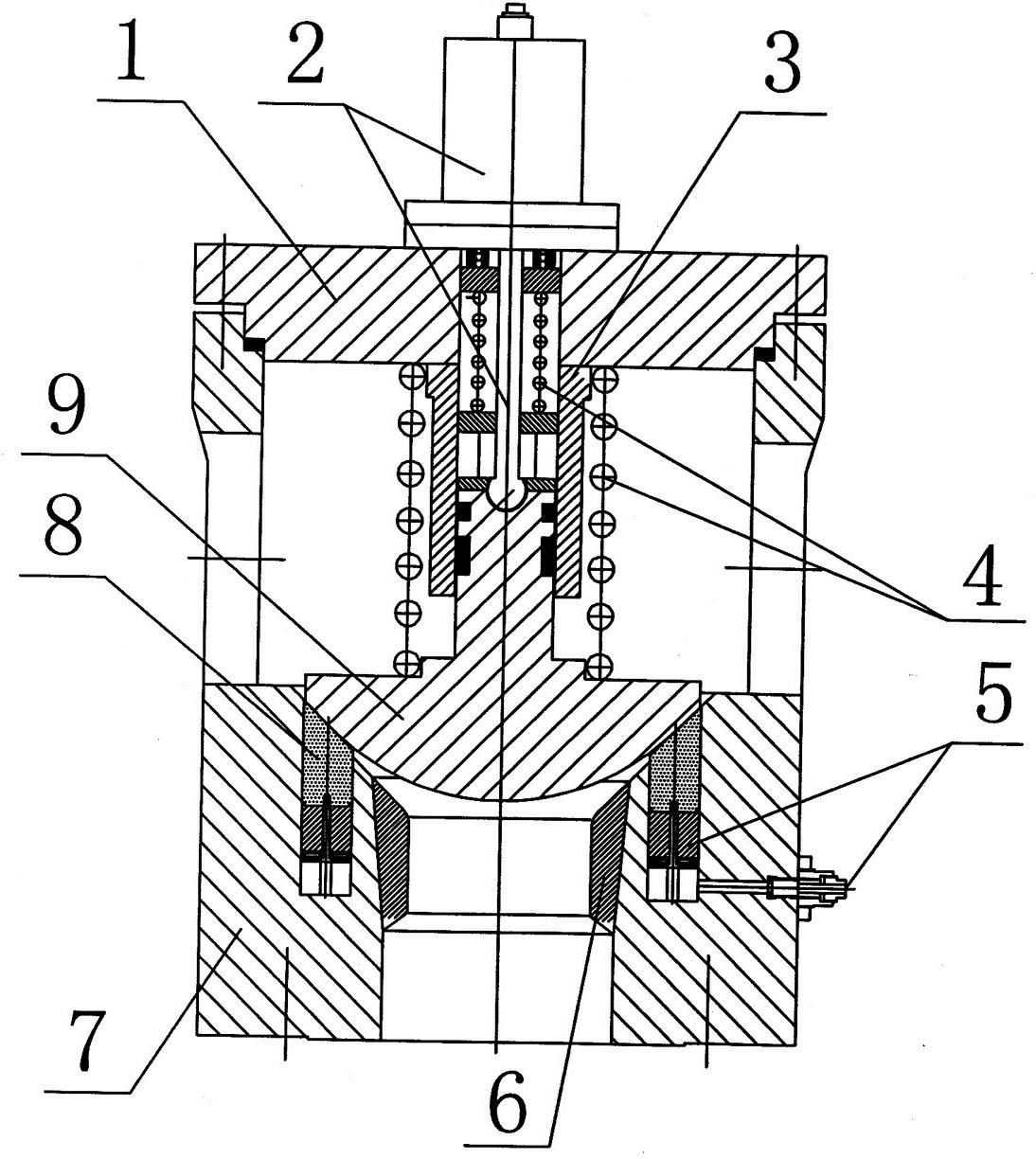

Valve rubber compensating type one-way valve

A compensation type, check valve technology, applied in the field of valve rubber compensation check valve, can solve the problem of fast replacement frequency of spare parts, and achieve the effect of reducing replacement frequency, improving the degree of self-control, and small ranging error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] A wear-resistant bushing 6 is provided on the inner hole wall of the valve body 7; a valve rubber extruding device 5 is arranged on the valve body 7, and the valve rubber 8 is arranged on the upper part of the valve rubber extruding device 5, and the valve rubber extruding device 5 passes through the valve body 7, inject the fluid medium into the valve rubber extruding device 5 through the upper injection hole, so as to extrude the valve rubber 8 from the upper end. At the same time, by controlling the injection amount of the fluid medium, the extrusion height of the valve rubber from the upper end can be controlled. When the valve cone 9 is in the non-working state, it is pressed on the valve rubber 8 by the spring 4. The outer part of the valve cone 9 is covered with a guide sleeve 3, which controls the trajectory of the valve cone 9 moving up and down. The inner side or the inner side and the outer side of the guide sleeve are arranged at the same time; the distance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com