Segmented water plugging method of liquid bridge plug of horizontal well

A technology for liquid bridges and horizontal wells, which is applied in the field of segmental water plugging of horizontal well liquid bridge plugs and segmental water plugging of horizontal wells to enhance oil recovery. It can solve the problems of lack of plugging agent products and injection techniques, and reduce construction costs risk, meet the use environment, and achieve the effect of oil layer protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The method for segmented water plugging of horizontal well liquid bridge plugs in this embodiment includes steps:

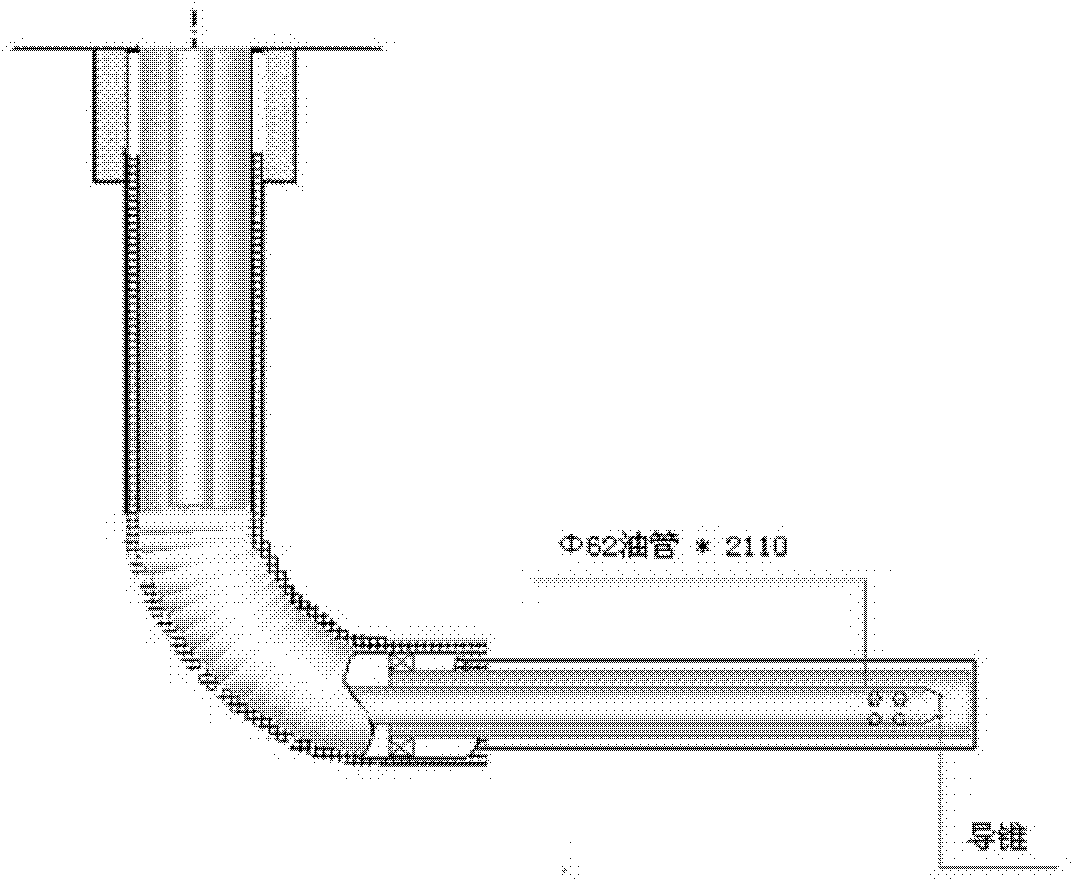

[0026] ① Lower the construction pipe string to the toe position of the horizontal well (see figure 1 ), open the casing gate, replace about 8.2 tons of liquid bridge plug, and then replace 6m 3 Clear water. The liquid bridge plug consists of 650Kg of acrylamide monomer, 1.6Kg of ammonium persulfate initiator, 80Kg of polyacrylamide (molecular weight 12 million), 100Kg of sodium chloride, and 7390Kg of water. The liquid bridge plug system is prepared according to the following method: slowly add the weighed polyacrylamide and acrylamide monomer into water under stirring, and continue to stir for 40 minutes; add ammonium persulfate and stir for 10 minutes; finally add chloride Sodium regulates density.

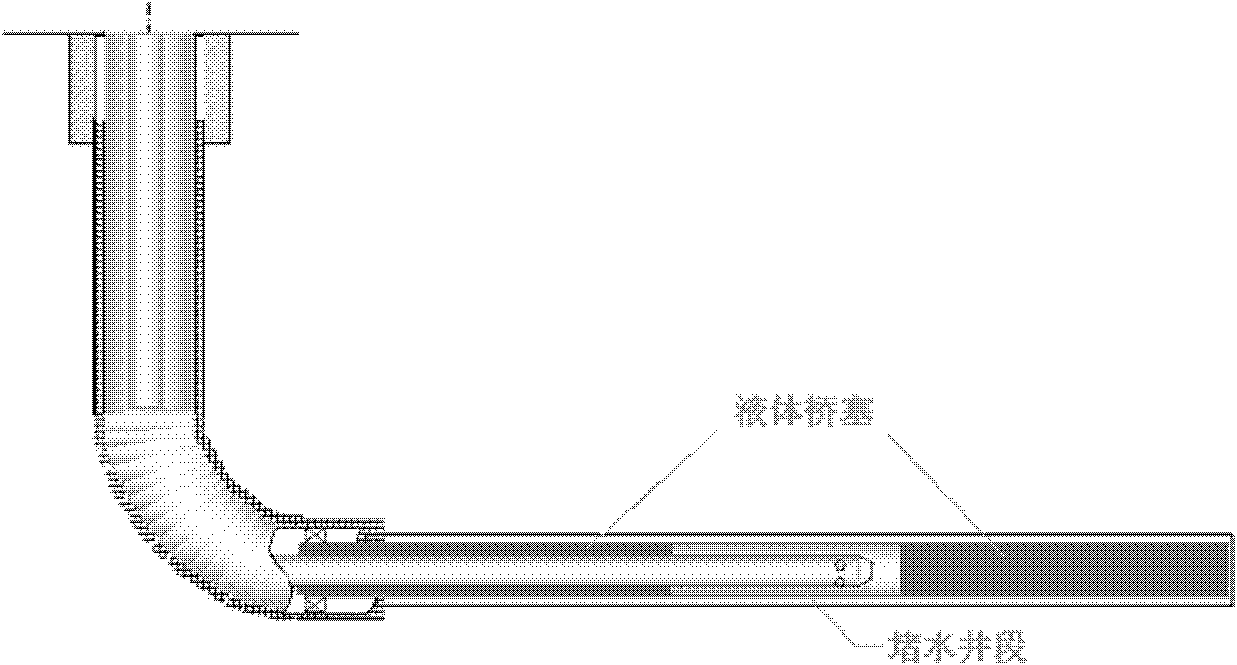

[0027] ② Lift the construction pipe string to the water outlet section (2020m), and replace clean water by 1.2m 3 , waiting for 24h;

[0028] The above...

Embodiment 2

[0033] The method for segmented water plugging of horizontal well liquid bridge plugs in this embodiment includes steps:

[0034] 1. Lower the construction string to the toe position of the horizontal well (2110m), open the casing gate, and replace about 5.2 tons of liquid bridge plug, followed by 6m replacement 3 Clear water; the liquid bridge plug consists of 460Kg of acrylamide monomer, 1.0Kg of initiator ammonium persulfate, 60Kg of polyacrylamide (molecular weight: 22 million), 100Kg of sodium chloride, and 4580Kg of water. The liquid bridge plug system is prepared according to the following method: slowly add the weighed polyacrylamide and acrylamide monomer into the water under stirring, and continue to stir for 30 minutes; add ammonium persulfate and stir for 5 minutes; finally add sodium chloride Adjust the density.

[0035] 2. After filling the liquid bridge plug, lift the construction pipe string above the suspension point (1700m), close the casing gate, and wait f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com