Large swirl injection flotation column

A flotation column and swirl technology, applied in flotation, solid separation and other directions, can solve problems such as inability to break through, dead ends of tailings and slag deposition, and bottlenecks encountered in large-scale flotation columns, so as to improve concentrate grade and recovery rate. Improved, prolonged flotation time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

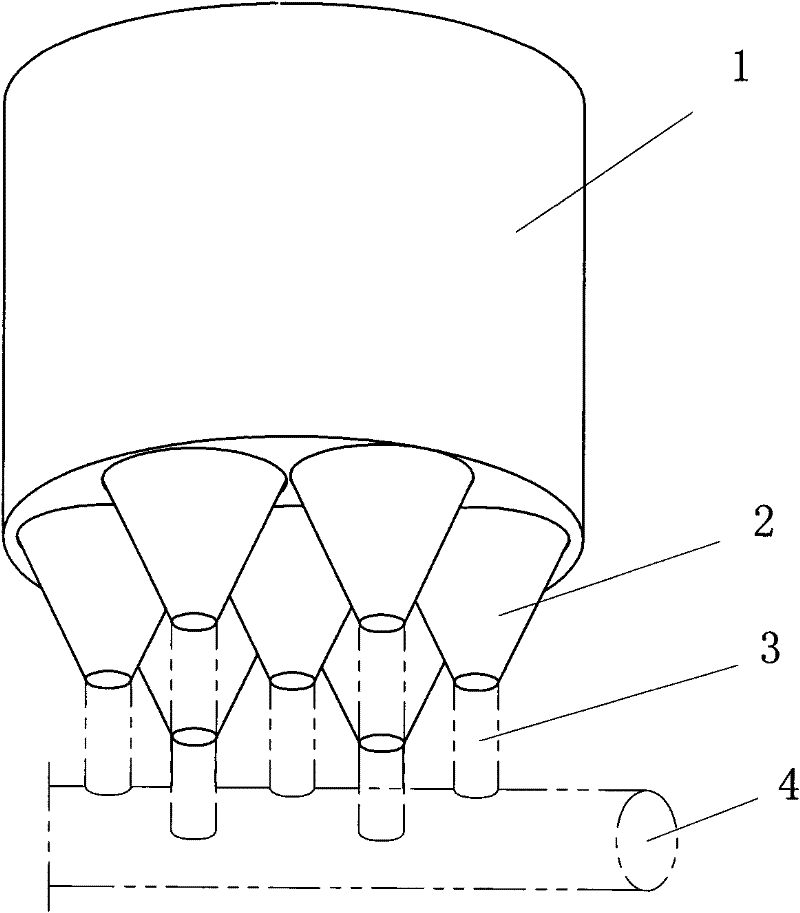

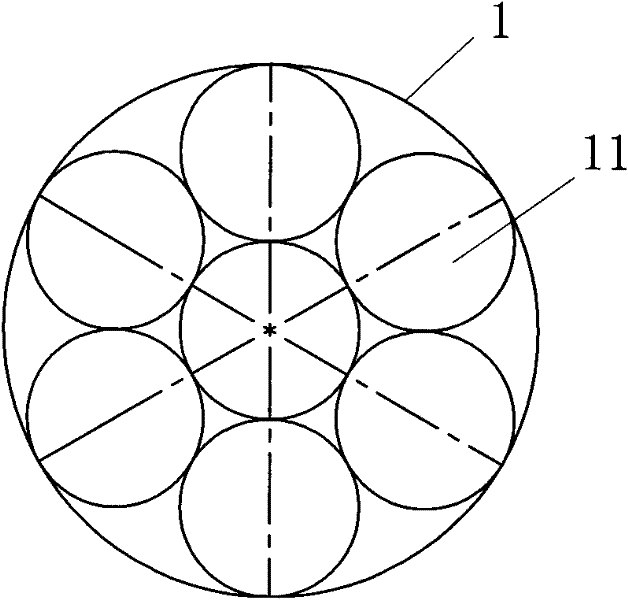

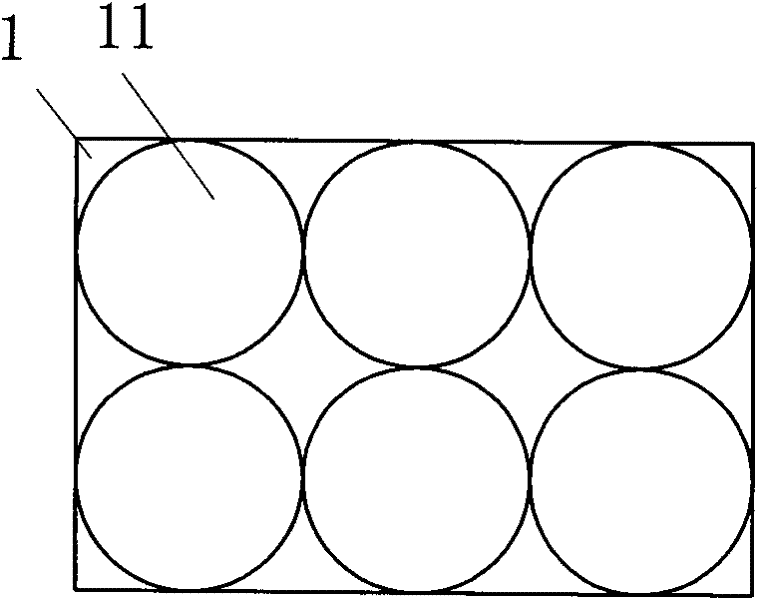

[0035] Such as figure 1 and Figure 4 Shown, a kind of large swirl jet flotation column provided by the present invention, its diameter is greater than 5 meters. The flotation column includes a flotation column cavity 1, an opening on the outer wall of the flotation column cavity 1, connected to a pulp inlet pipe 11, a swirl jet aerator 12 is installed on the pulp inlet pipe, and the flotation column The bottom of cavity 1 is provided with more than one opening. In this embodiment, seven openings 13 are provided. Below each opening 13, a tapered outlet pipe 2 is connected for tailings discharge. The area of the outlet end of the outlet pipe is less than The area of the opening at the bottom of the cavity is a tapered tube 2 with a large top and a small bottom.

[0036] This tapered pipe 2 is preferably swirl tapered pipe 21, namely as Figure 5 , 6 As shown, a spiral rib 21a is provided on the inner wall of the tapered pipe, so that the tailings slurry flowing through ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cone angle | aaaaa | aaaaa |

| Cone angle | aaaaa | aaaaa |

| Cone angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com