Method for determining gradient of traction wheel of enameled wire mold with diameter less than 0.2 mm

A technology of enameled wire and traction wheel, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., to achieve the effect of improving utilization rate and utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

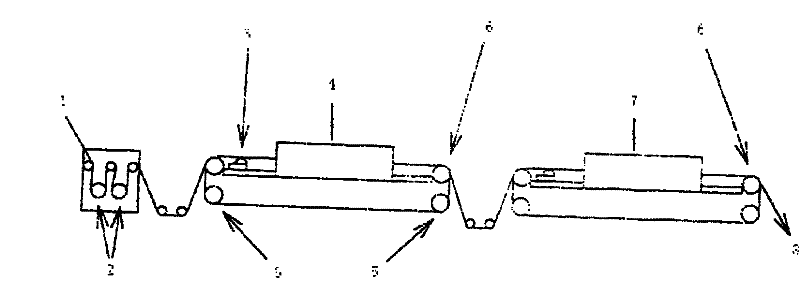

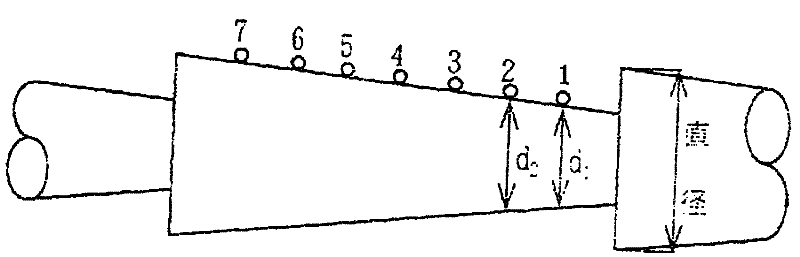

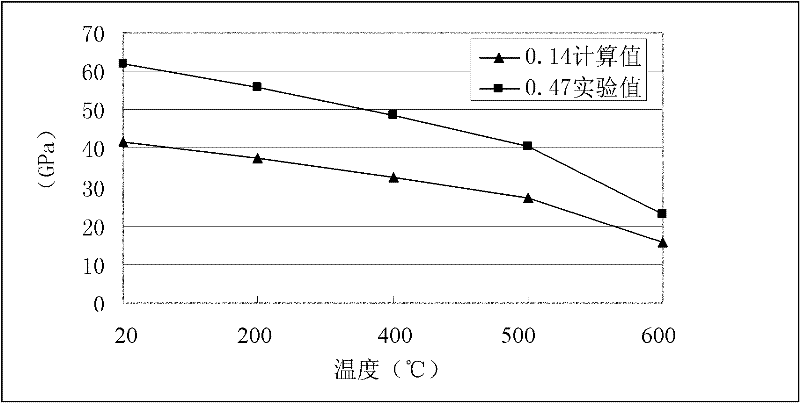

[0030] Such as figure 1 , 2 , 3, and 4, firstly calculate the elastic modulus of the enameled wire in the enamelling machine furnace according to the high temperature test results, and the sample wire used in the high temperature test is 0.47mm and 0.14mm self-adhesive wire. The enameled wire during the baking and painting process is always pulled by the traction wheel to produce strain (stretch). For the elastic body, the relationship between stress and strain is shown in the following formula:

[0031] σ = Eε

[0032] where σ: stress, E: modulus of elasticity, ε: strain

[0033] Test the elastic modulus of self-adhesive enameled wire with a conductor diameter greater than 0.2mm. Firstly, the high-temperature tensile test is carried out on a relatively thick 0.47mm self-adhesive wire to obtain the corresponding basic data:

[0034] After testing, after complete annealing, the elastic modulus E1 of enameled copper wire coated with paint film at a temperature of 20°C is 81...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com