Three-dimensional visual inspection system with small size and large base line distance for automobile wheel positioning parameter

A technology of wheel positioning and three-dimensional parameters, which is applied in the direction of wheel testing, measuring devices, instruments, etc., to achieve the effects of reducing the time for installing sensors, low production costs, and non-contact measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

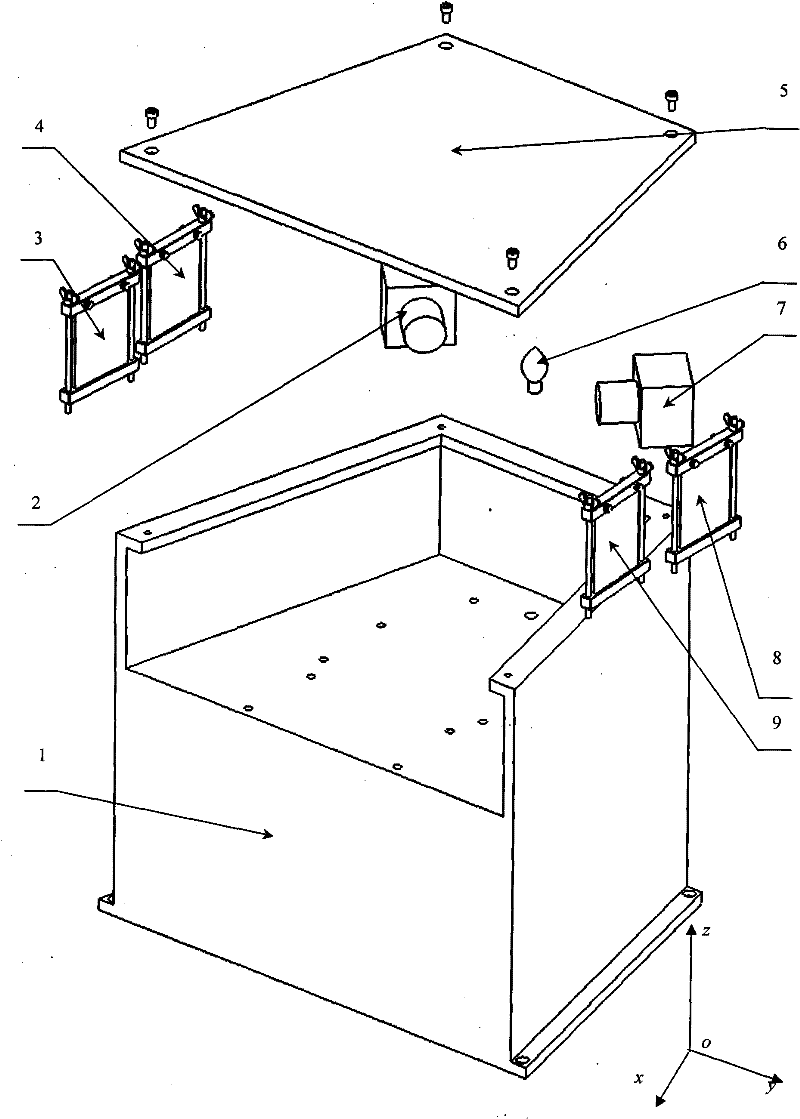

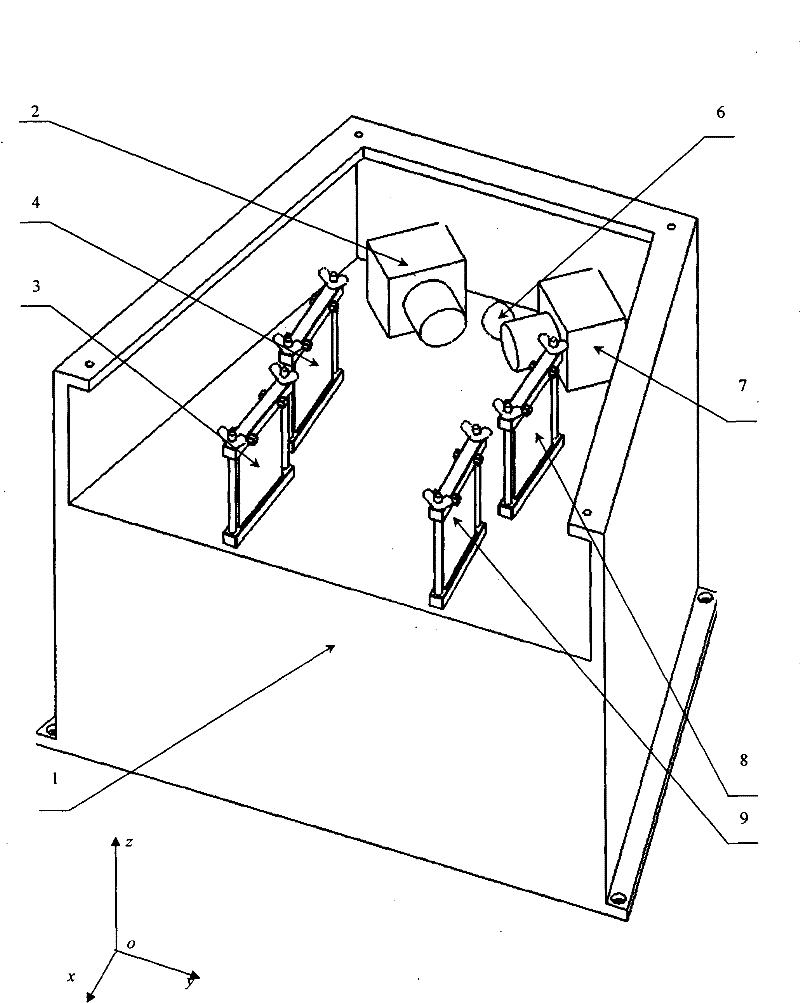

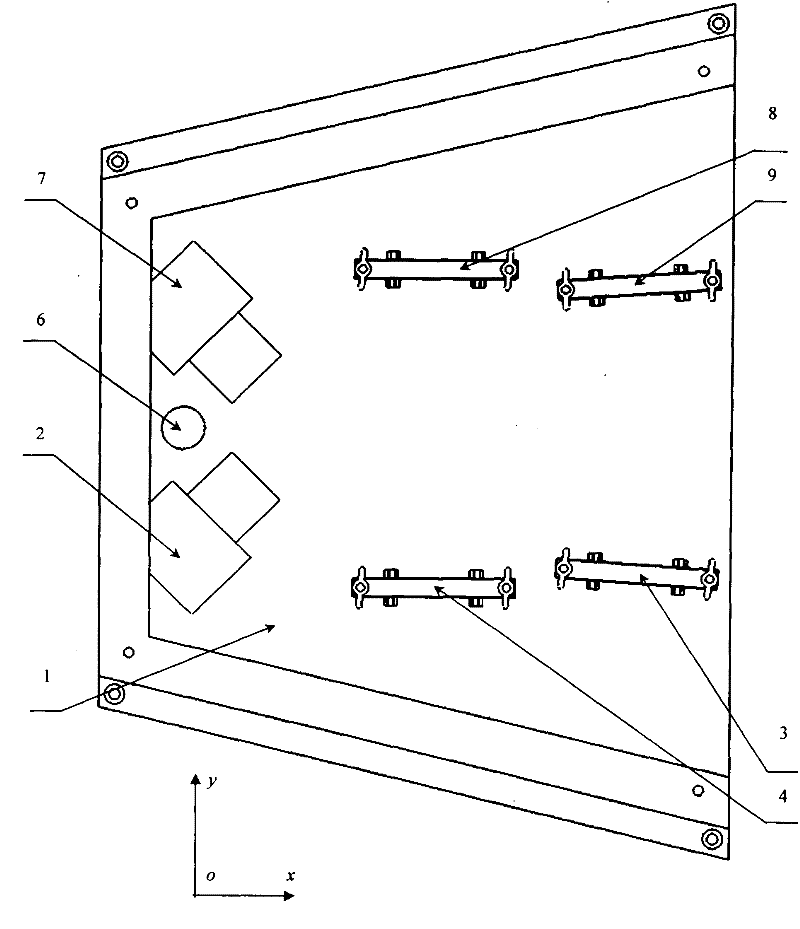

[0034] Below in conjunction with accompanying drawing, the present invention will be described in further detail:

[0035] The invention provides a car wheel positioning parameter stereo vision detection system with small size, simple installation, stable performance, accurate detection result and high precision, which has small size and long baseline distance. The invention can be applied to automobile manufacturers, automobile inspection equipment manufacturers, automobile inspection centers, automobile maintenance enterprises, universities, scientific research institutes and national measurement and quality supervision departments.

[0036]The invention adopts the method of secondary reflection of the plane mirror to increase the virtual baseline distance between the two cameras, and solves the problem that the system baseline distance is increased to improve the measurement accuracy and thus the system size is too large. The lighting source is set in the system, which is b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com