Component type high-pressure common rail device

A high-pressure common rail and component-based technology, which is applied in fuel injection devices, charging systems, engine components, etc., can solve problems such as low pressure stability and pressure fluctuations, so as to improve pressure stability, reduce pressure fluctuations, The effect of ensuring pressure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

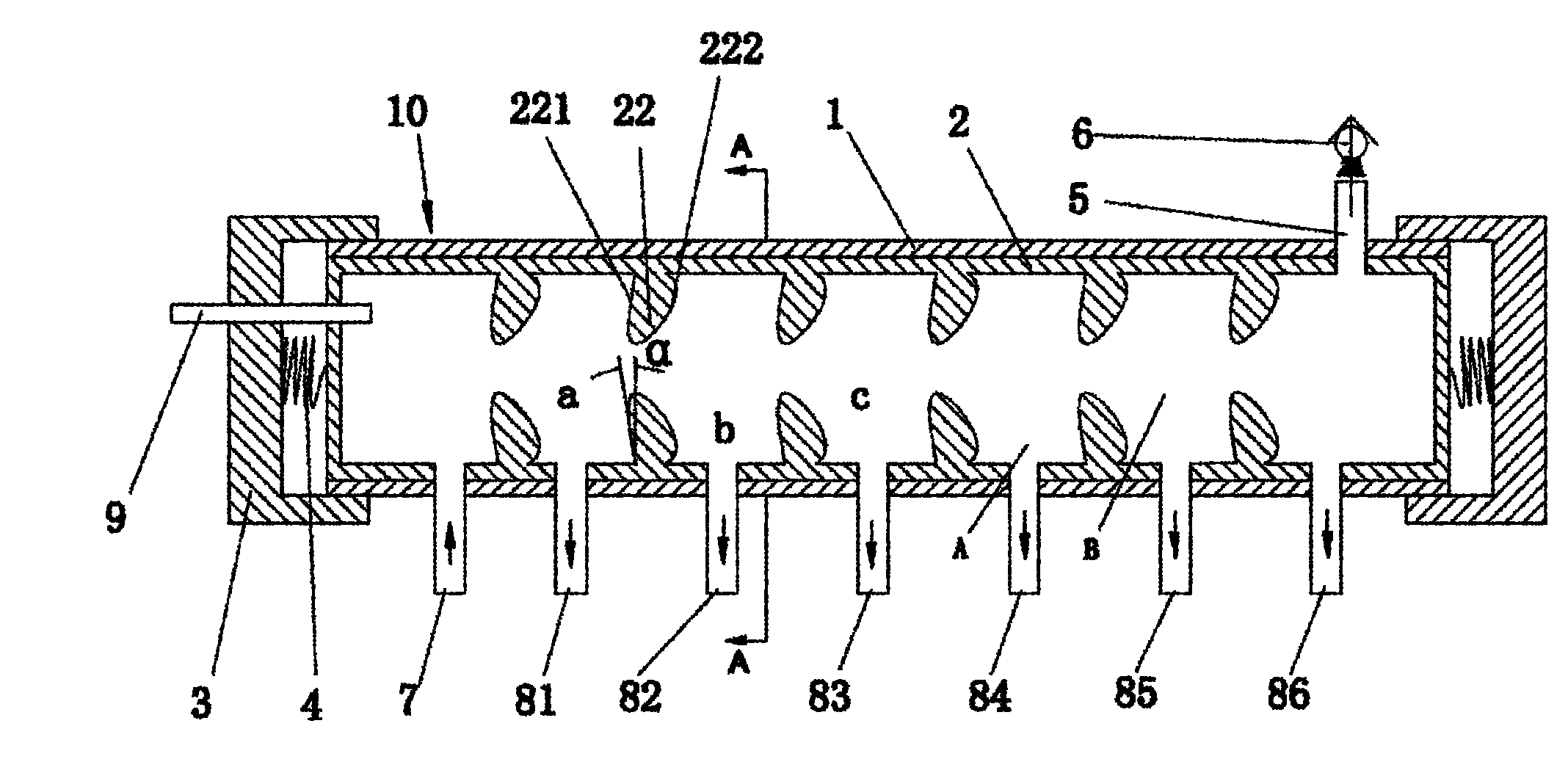

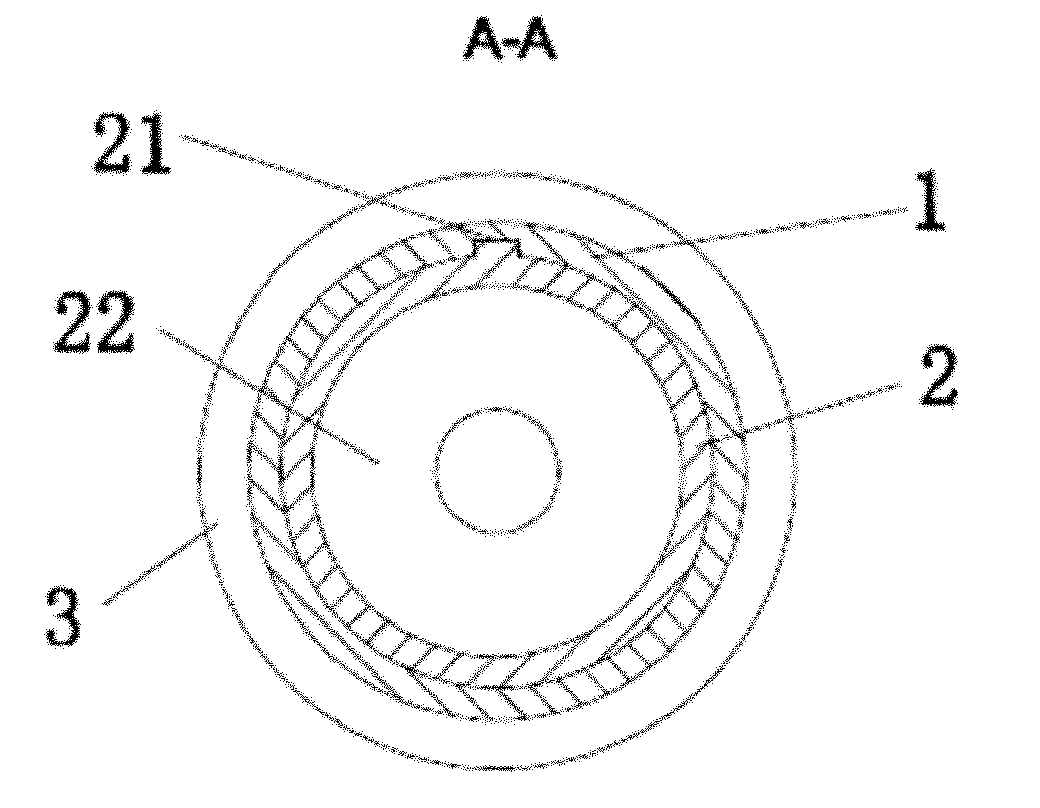

[0019] see Figure 1 ~ Figure 4 , a component type high-pressure common rail device, including a common rail pipe 10, a pressure limiter 6 is provided on the drain hole 5 of the common rail pipe 10, and an inner Pressure sensor 9 for chamber pressure. The common rail pipe 10 includes an inner pipe 2 and an outer pipe 1 sleeved on the inner pipe 2 and having openings at both ends; The inner peripheral surfaces of the tubes 1 are matched with each other and there is a gap fit between the two; the inner tube 2 and the outer tube 1 are provided with a circumferential limit for limiting the circumferential rotation between the inner tube 2 and the outer tube 1 device; the two ends of the outer tube 1 are fixedly sleeved with a sealing cover 3 for sealing the two ends of the outer tube 1; one end of the sealing cover 3 is a closed end, the other end of the sealing cover 3 is an open end, and the sealing cover The opening end of 3 is sleeved on the outer peripheral surface of the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com