Test device for studying distribution of plume condensed-phase particles of spray pipe

A particle distribution and test device technology, applied in jet propulsion devices, rocket engine devices, machines/engines, etc., can solve problems such as lack of understanding, lack of test devices, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0017] In this embodiment, a research experiment is carried out using the test device proposed by the present invention, and the influence of factors such as particle phase concentration, working pressure and nozzle configuration on the particle size distribution of the condensed phase is solely studied.

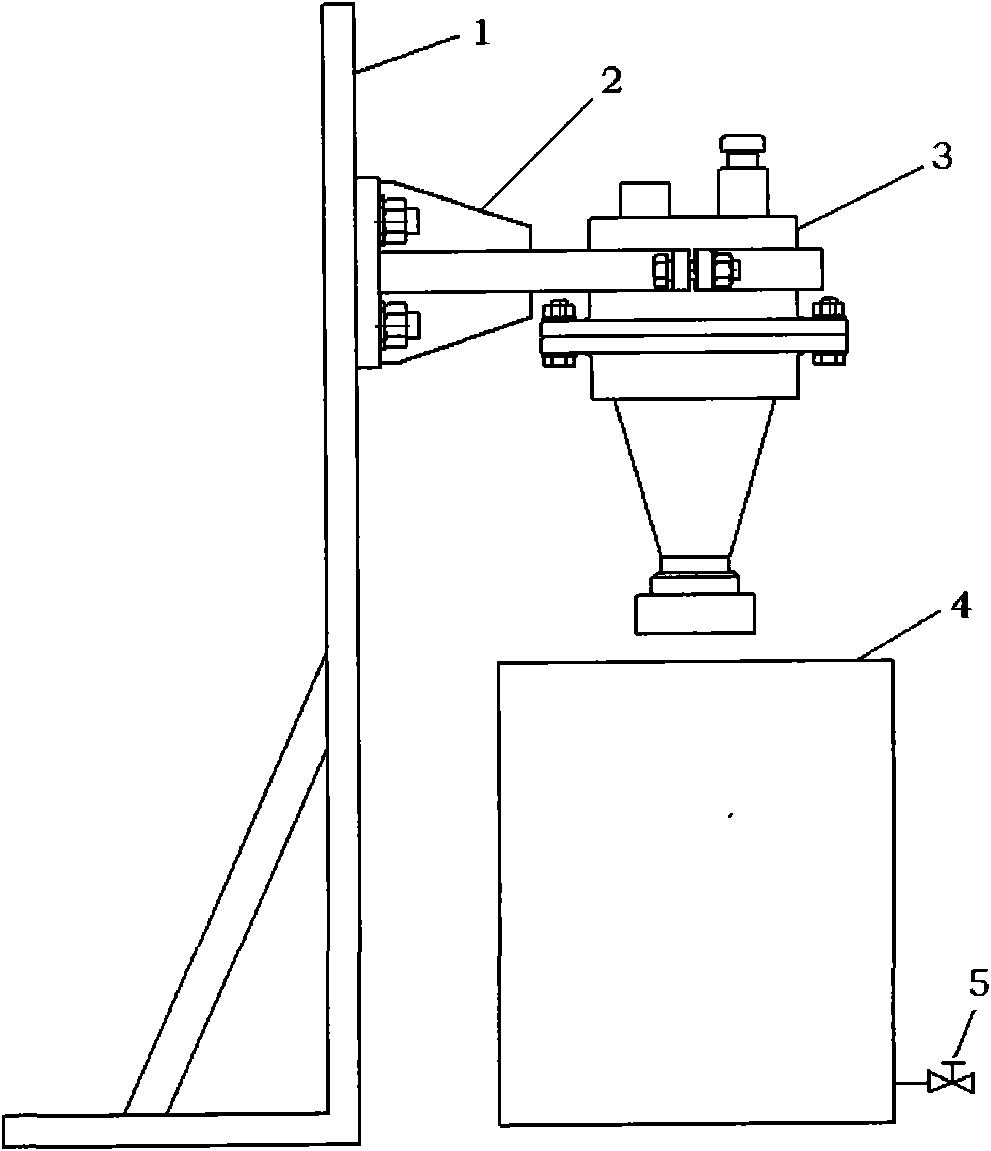

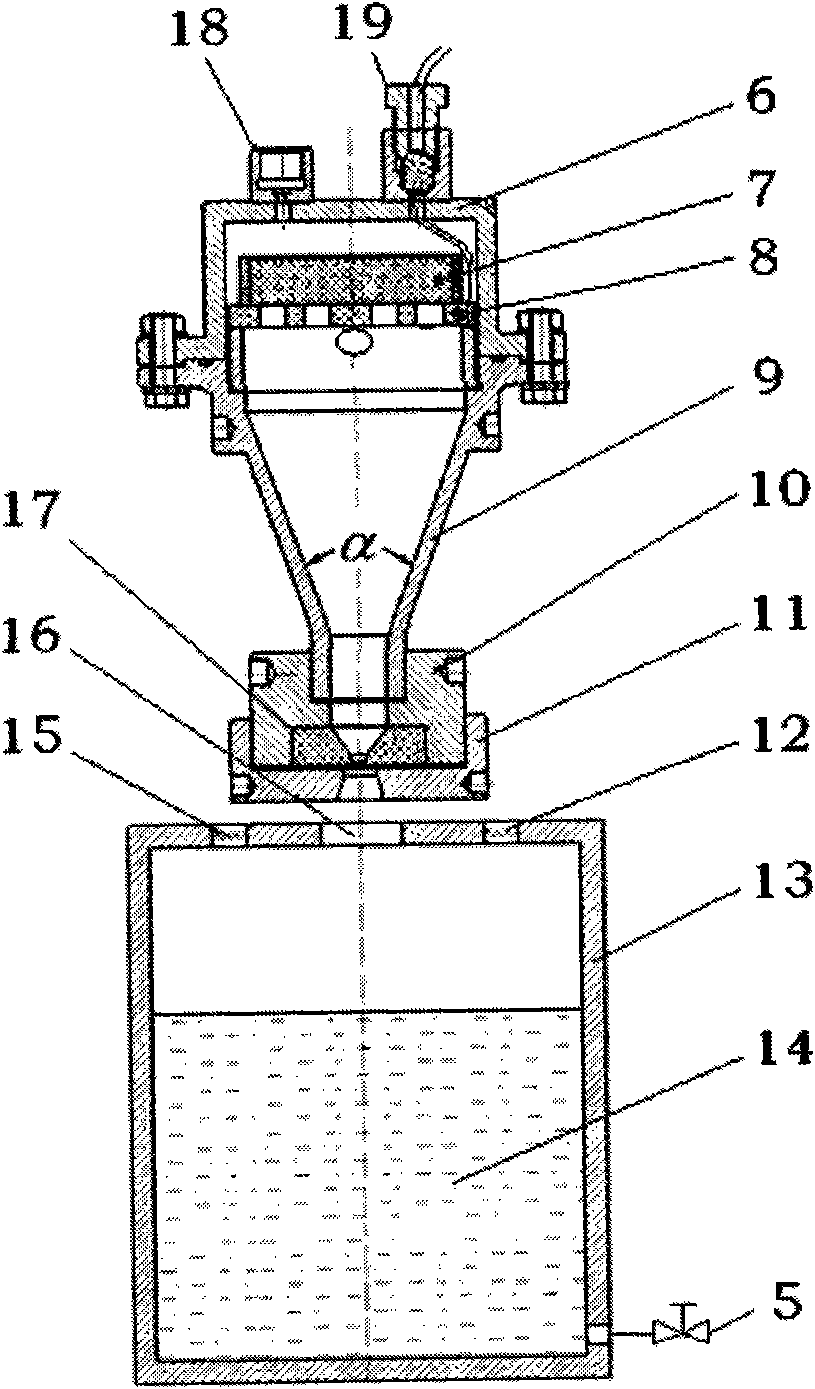

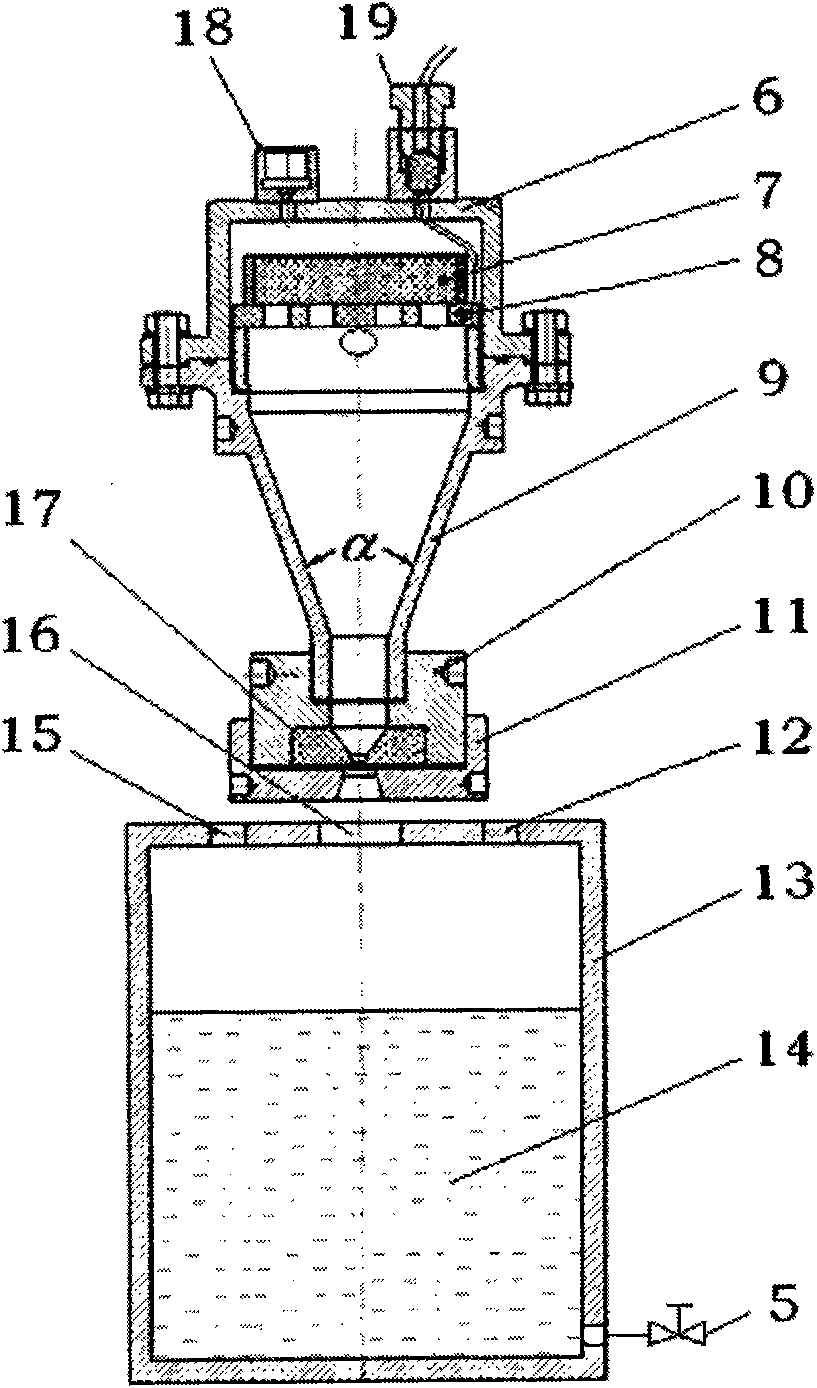

[0018] Refer to attached figure 1 And attached figure 2 , the test device in this embodiment includes a gas generator 3 and a particle collection device 4, the gas generator 3 is fixed on the test bench 1 through a gas generator bracket 2; the particle collection device 4 is placed below the gas generator 3, and for collecting condensed phase particles.

[0019] Refer to attached figure 2 , The gas generator 3 includes a combustion chamber 6 , a converging section 9 and a nozzle 17 . In the combustion chamber 6, a medicine retaining plate 8 is fixed, and the medicine retaining plate 8 is a plate-shaped structure with a gas hole. There is a propellant 7 between the medic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com