Finalized rebar machining shed

A technology for processing sheds and steel bars, which can be used in construction, building construction, and building materials processing, etc., and can solve the problems of large investment, poor safety performance, and slow erection speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

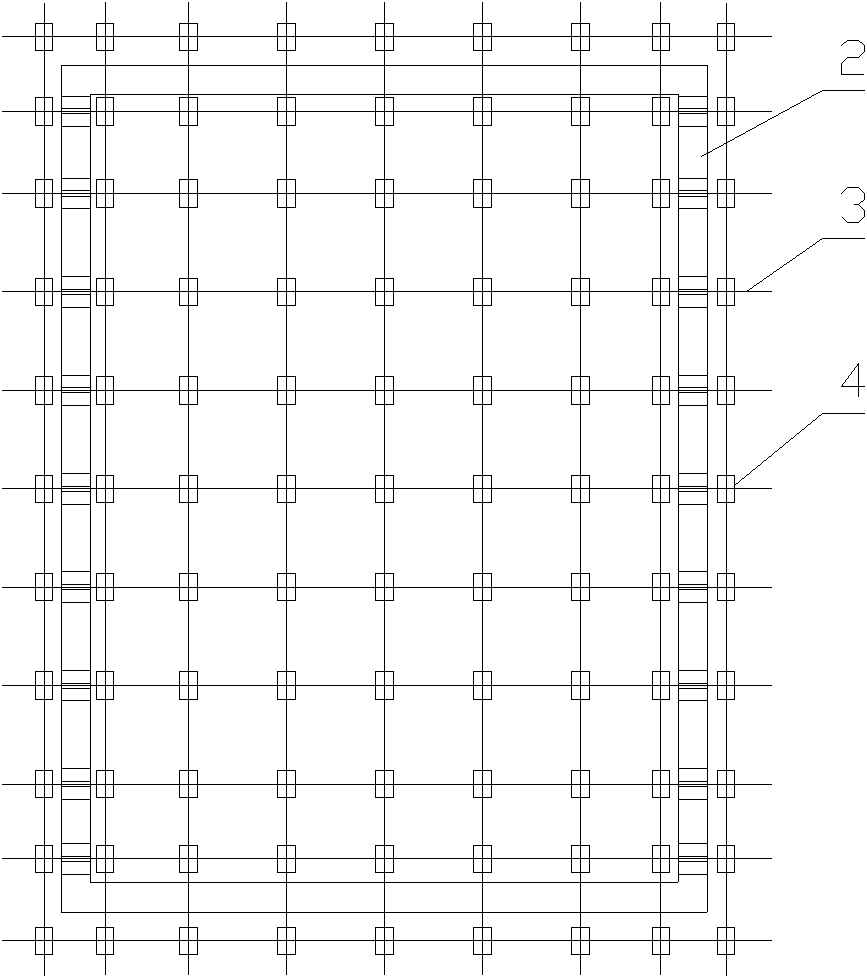

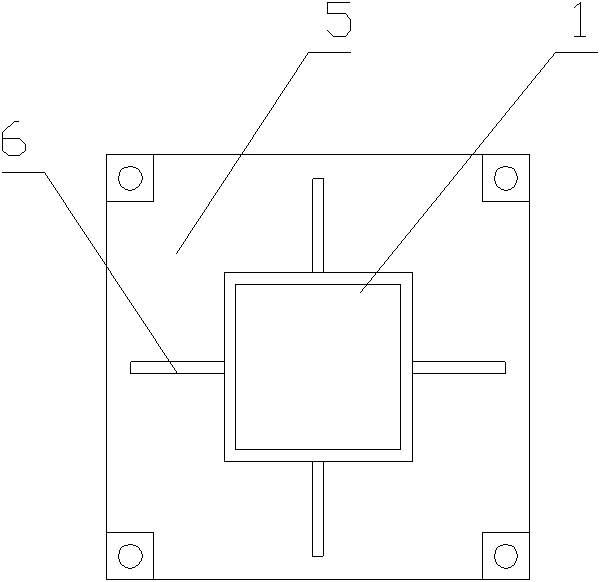

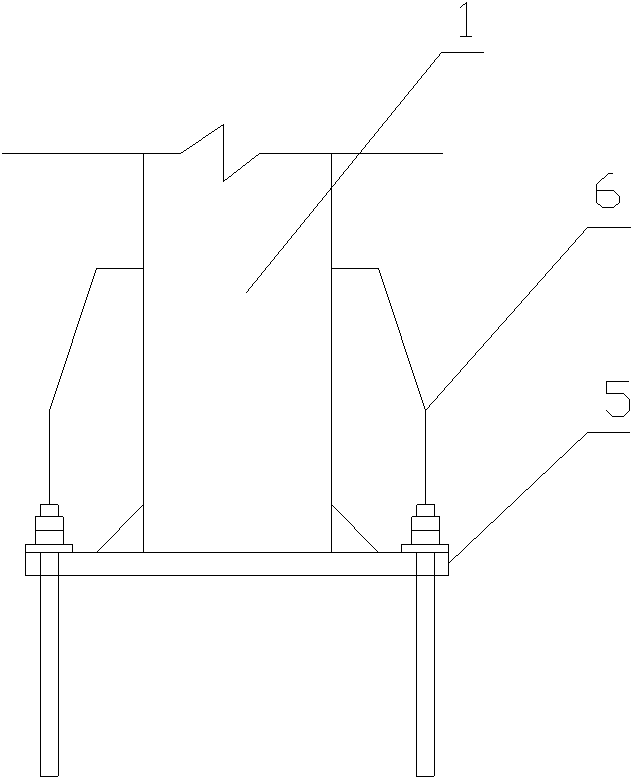

[0025] Such as Figure 1 to Figure 9 As shown, it is an embodiment of the stereotyped steel bar processing shed of the present invention, including a vertical support member 1 fixed on a concrete foundation, the vertical support member is enclosed in a circle and a circle of main beams 2 is fixed on the top, and the main beam Steel pipes 3 are arranged at the upper intersection, and the steel pipes are fixed on the main beam by fasteners 4, and the intersections of the steel pipes are also fixed by the fasteners, and a ceiling panel 9 is laid on the steel pipes. The main beam 2 is square, and the steel pipes 3 on the main beam are vertically intersected. The vertical supporting member 1 is a box-shaped steel column, and a bottom plate 5 is welded to the bottom of the box-shaped steel column, and the bottom plate is fixed on the concrete foundation through anchor bolts. The root of the steel column is provided with stiffeners 6, and the anchor bolts are fixed with double nuts....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com