Floorboard for floor heating

A geothermal floor and substrate technology, applied in the field of floor and geothermal floor, can solve the problems of poor heat transfer effect, difficult processing and manufacturing, easy heat loss, etc., and achieve the effect of convenient assembly and maintenance, short heat transfer path and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

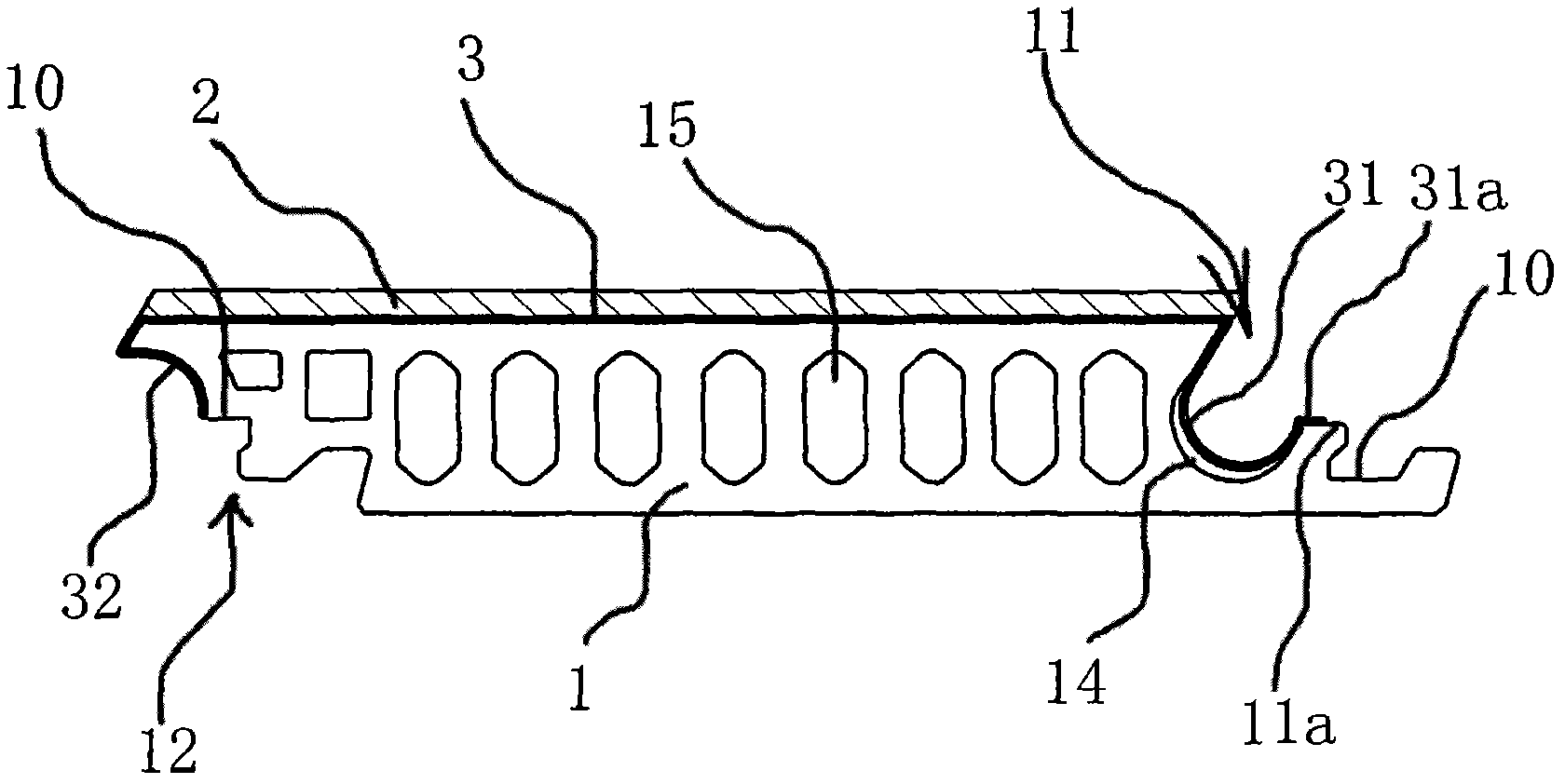

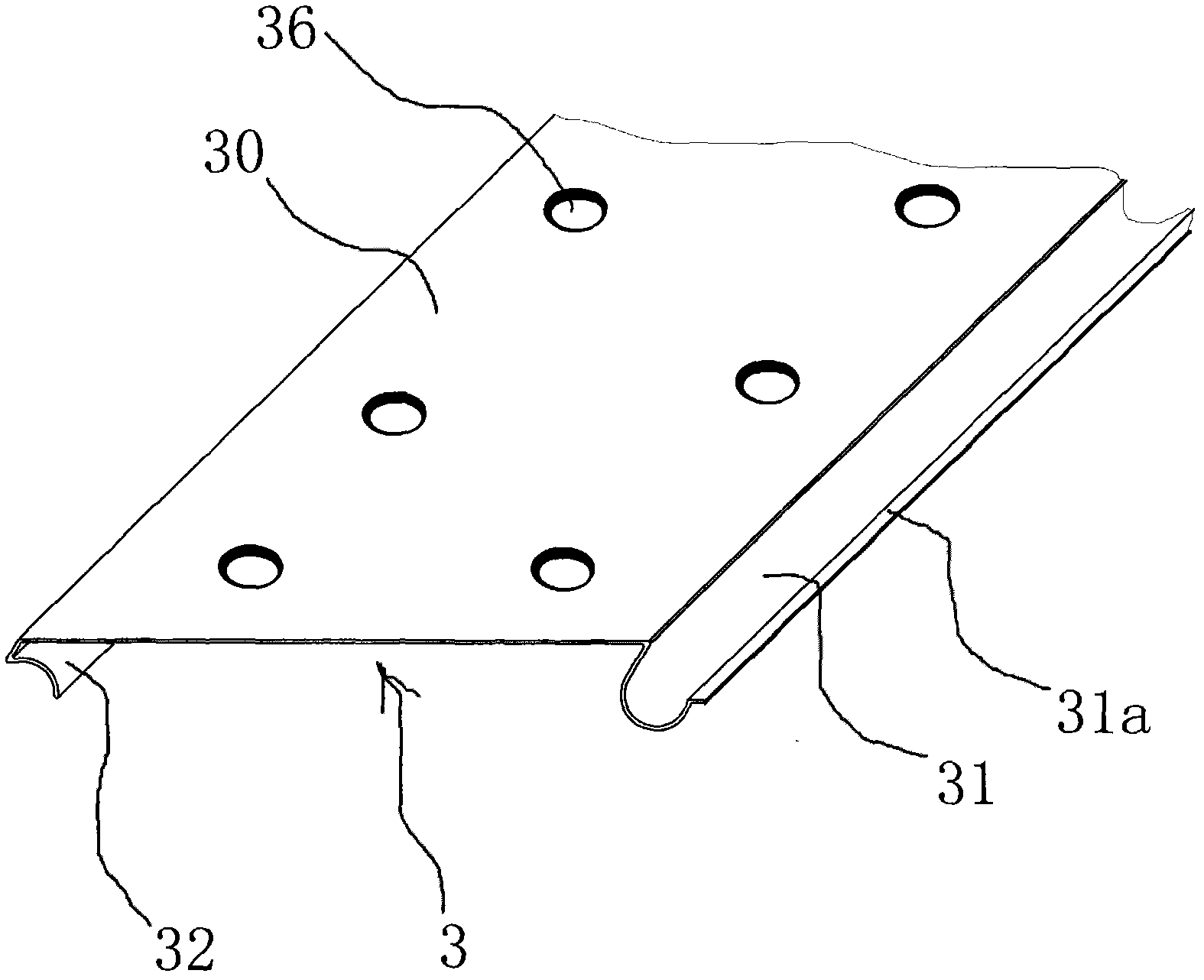

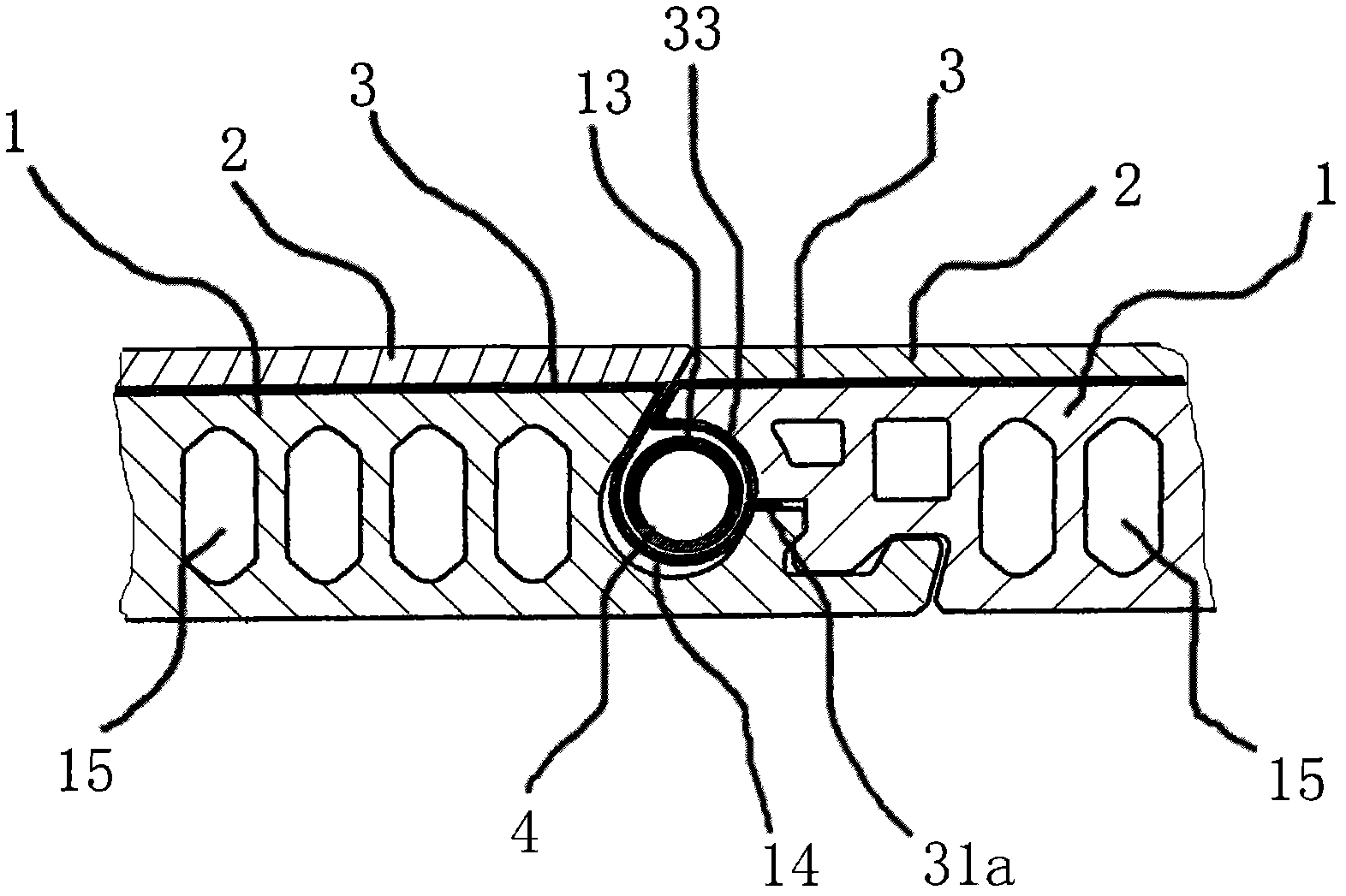

[0030] Such as figure 1 and 3 As shown, the local heating floor includes a base plate 1, a first connection structure 11 is provided on one side of the base plate 1, and a second connection structure 12 is provided on the other side. The first connection structure 11 and the second connection structure 12 respectively have concave-convex joint portions 10 . The first connecting structure 11 on one substrate 1 and the second connecting structure 12 on another adjacent substrate 1 can be snapped together, and when the first connecting structure 11 and the second connecting structure 12 are snapped together, they can form a longitudinal Extended accommodating cavity 13 . A decorative surface plate 2 is compounded on the front of the substrate 1 , and a heat-conducting medium layer 3 made of a heat-conducting material is provided between the substrate 1 and the decorative surface plate 2 . The heating element 4 extending longitudinally can be accommodated in the accommodating c...

Embodiment 2

[0035] Such as Figure 4 and 5 As shown, in this embodiment, the side of the heat conducting part 30 facing the substrate 1 has a longitudinally extending duct 34 , and the substrate 1 is provided with a longitudinally extending groove 16 for placing the duct 34 . The pipeline 34 is located on the center line of the heat conducting part 30 , and another heating body 4 is installed in the pipeline 34 . The rest are similar to those in Example 1, and will not be described in detail.

Embodiment 3

[0037] Such as Figure 6 As shown, in this embodiment, the heat conduction part 30 is composed of a first sheet-shaped body 301 and a second sheet-shaped body 302 which are arranged separately. The joint seam of the first sheet body 301 and the second sheet body 302 is located on the center line of the heat conducting part 30 . The rest are similar to those in Example 1, and will not be described in detail.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com