Intelligent GPS (global positioning system) elevation and average thickness control system of floated screed plate paver

A technology of average thickness and paver, applied in the direction of roads, road repairs, roads, etc., can solve the problems of inaccurate reference elevation, influence of control accuracy, limited quantity, etc., and achieve the effect of eliminating manual measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

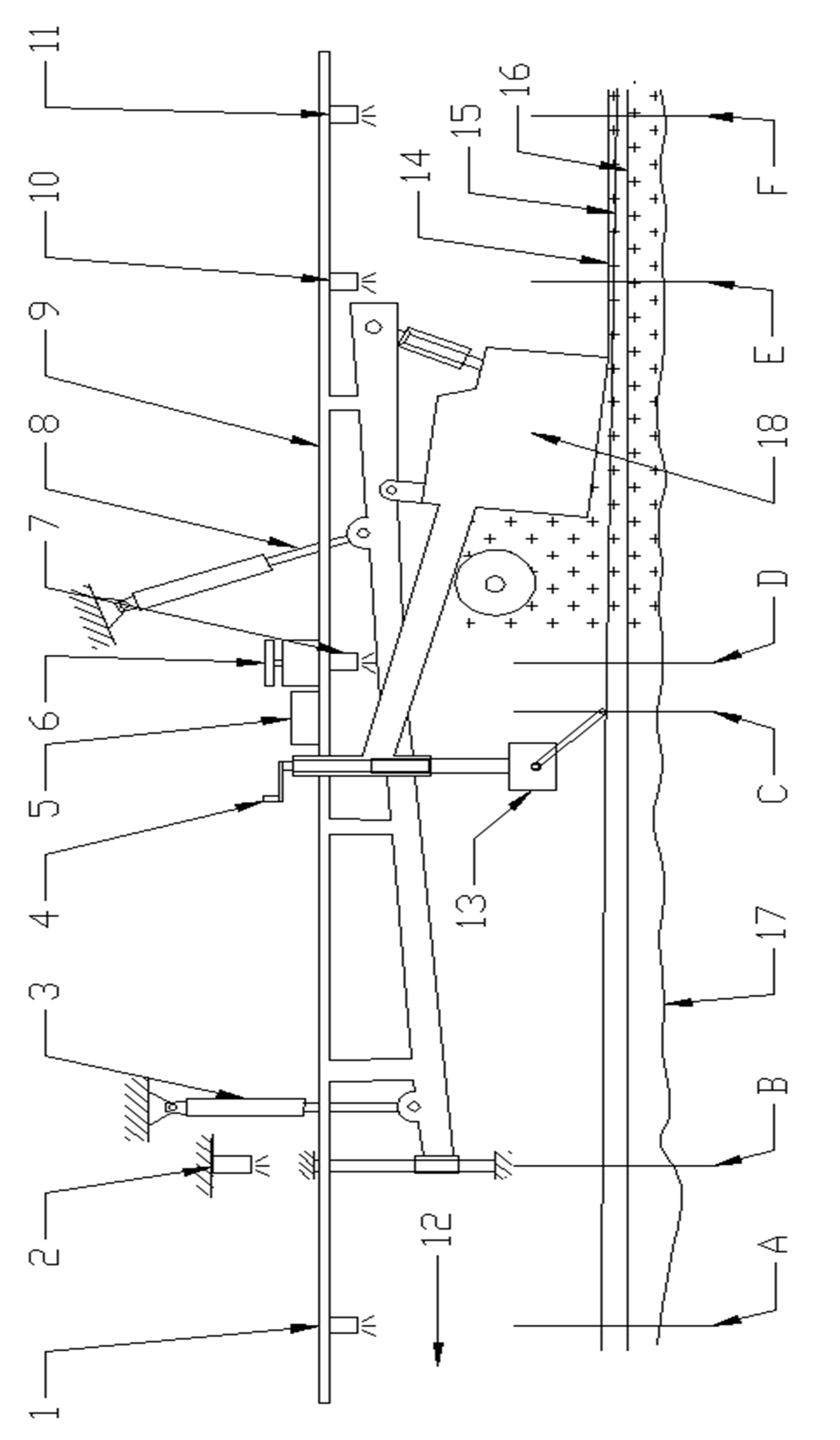

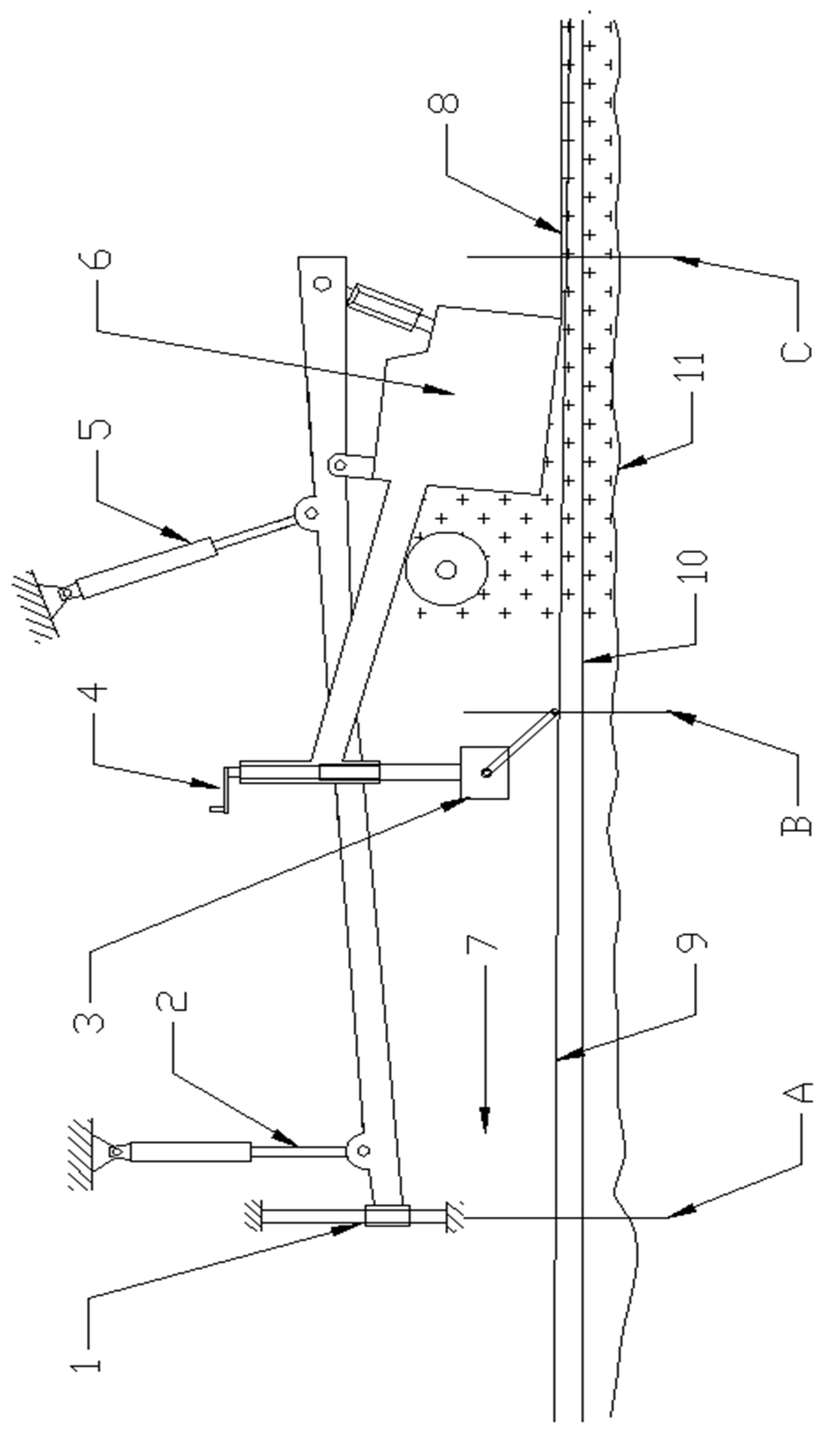

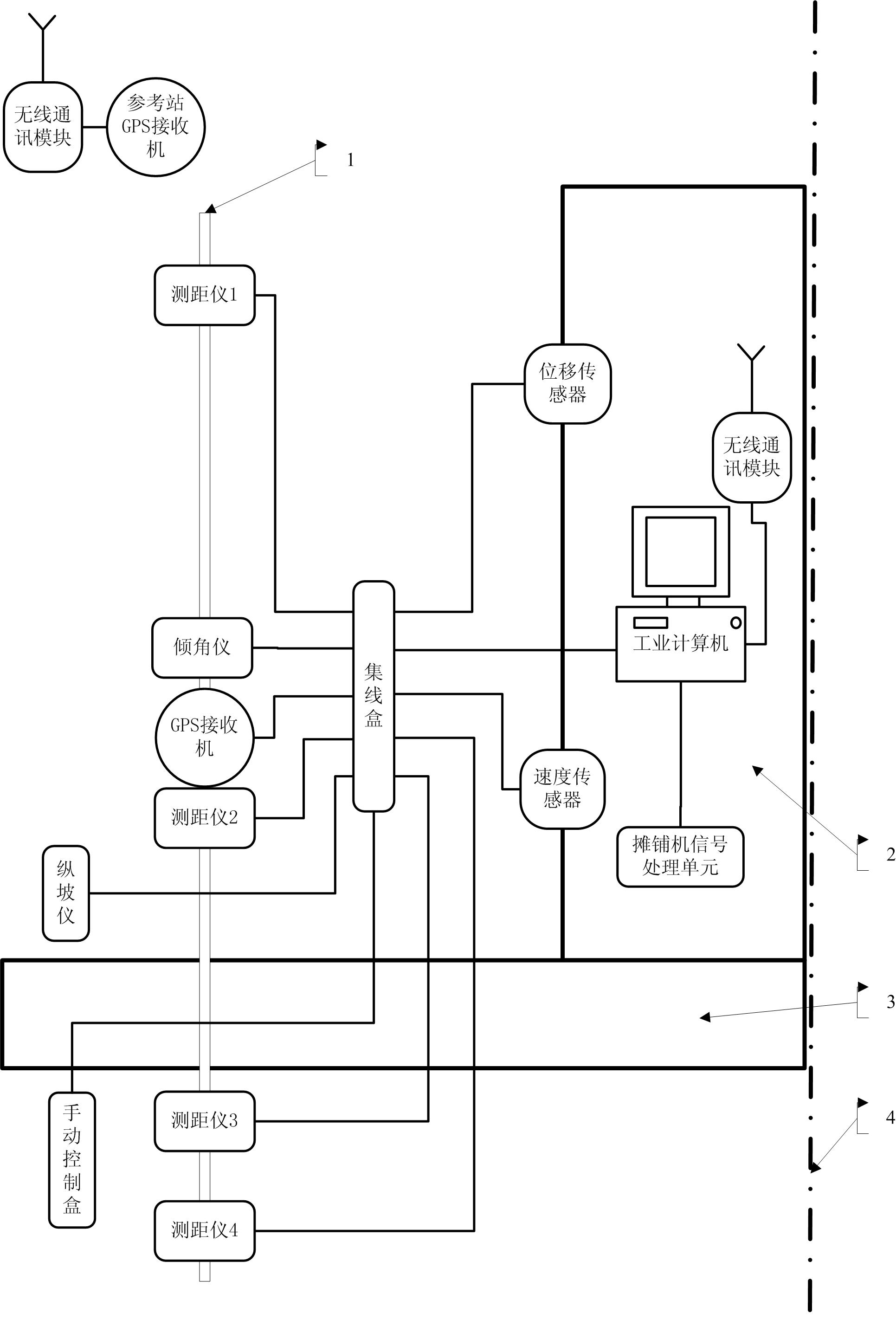

[0053] figure 1 and image 3 They are respectively the elevation schematic diagram and the plane schematic diagram of Embodiment 1 of the present invention. The composition and respective functions of the equipment in Embodiment 1 will be described below.

[0054] Such as image 3 As shown, 1 industrial computer, 1 reference station GPS receiver, 1 set of wireless data communication equipment, 1 displacement sensor, 1 speed sensor, 4 range finders, 1 mobile station GPS receiver, 1 longitudinal Slope meter, 1 manual control box and 1 junction box form the semi-width control system of the intelligent GPS elevation and average thickness control system of the floating screed paver, which can work independently and control the paver elevation on one side of the paver. Map No. 4 is the longitudinal center line of the paver. If the other half is also installed with 1 displacement sensor, 1 speed sensor, 4 range finders, 1 mobile station GPS receiver, 1 vertical slope meter, 1 1 ...

Embodiment 2

[0067] On the basis of Example 1, a mobile station GPS receiver is added to the intelligent GPS elevation and average thickness control system of the half-width floating screed paver, the inclinometer is removed, and the two mobile station GPS receivers are respectively installed on the figure 1 The position number 1 and the position number 10 in the map, so that the three-dimensional coordinates of point A17 can be obtained through the GPS receiver and range finder of the 1 position mobile station, and the E14 point can be obtained through the GPS receiver and the range finder of the 1 position mobile station For the three-dimensional coordinates of the points, this embodiment is the same as Embodiment 1 in other respects, except that the method of obtaining the coordinates of the original road surface point and the newly paved road surface point is different.

Embodiment 3

[0069] On the basis of Embodiment 1, the working method of the current RTK surveying GPS receiver is the same, the mobile station GPS receiver directly receives the data of the reference station GPS receiver and corrects its own measurement data in real time, and then sends the corrected data to For industrial computer use. The industrial computer does not undertake the calculation work of RTK.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com