Automatic clamping intelligent welding equipment for medical multifunctional electric nursing bed bedpan bracket

A nursing bed, multi-functional technology, applied in welding equipment, welding equipment, auxiliary welding equipment and other directions, can solve the problems of large concentricity error of the front mounting hole, errors in manual measurement and group pairing, and large errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

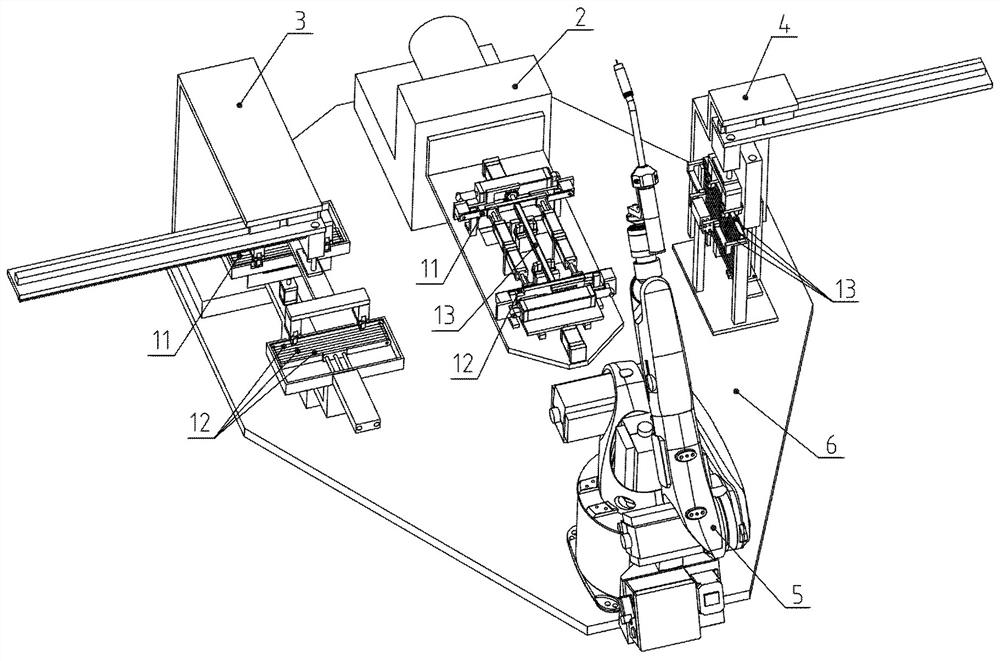

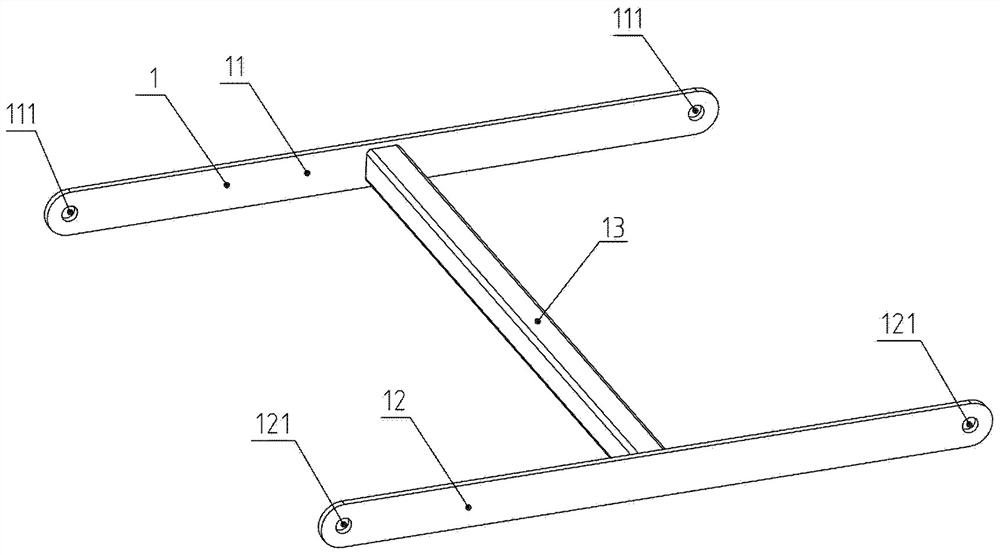

[0062] Example: see Figure 1 to Figure 19 .

[0063] An intelligent welding equipment for automatic clamping of the bedpan support of a multifunctional electric nursing bed for medical care, including a turner 2, a bar feeder 4, an intelligent welding robot 5 and a frame 6; the base of the intelligent welding robot 5 is fixed to the frame 6 connection;

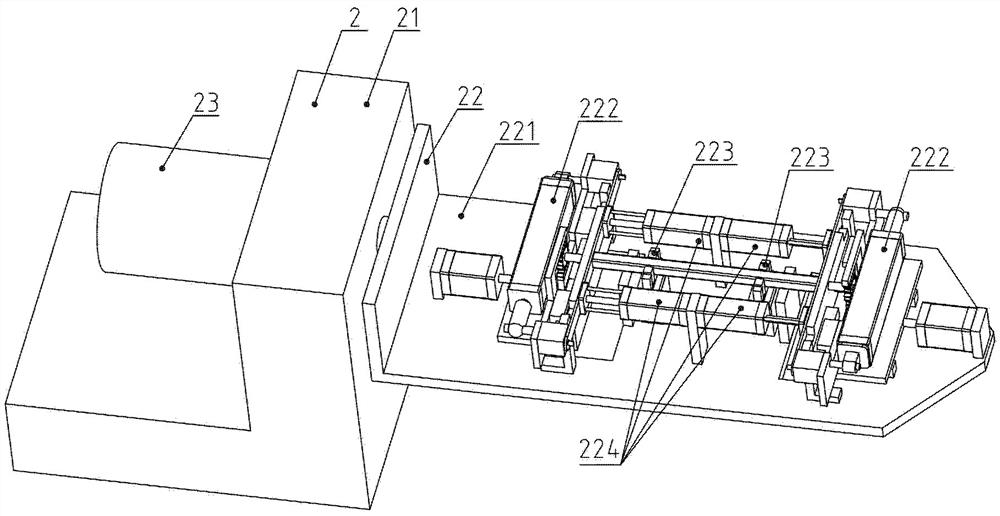

[0064] Turner 2 includes turning support 21, turning assembly 22 and turning servo motor 23; Turning support 21 is fixedly connected with frame 6; Turning assembly 22 includes turning frame 221; Turning frame 221 includes the turning plate assembly 2211 and Turning shaft 2212; Turning shaft 2212 and turning support 21 are connected by rotating pair; Turning shaft 2212 is positioned at the front end of turning plate assembly 2211, and the axis line of turning shaft 2212 is arranged in the front and rear horizontal direction; Turning the shell of servo motor 23 and turning support The seat 21 is fixedly connected through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com