Opening buffer electric disassembly tooling

A buffer and tooling technology, which is applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of wasting working hours and manpower, time and effort, etc., and achieve the effects of eliminating errors, improving work efficiency, and facilitating disassembly and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

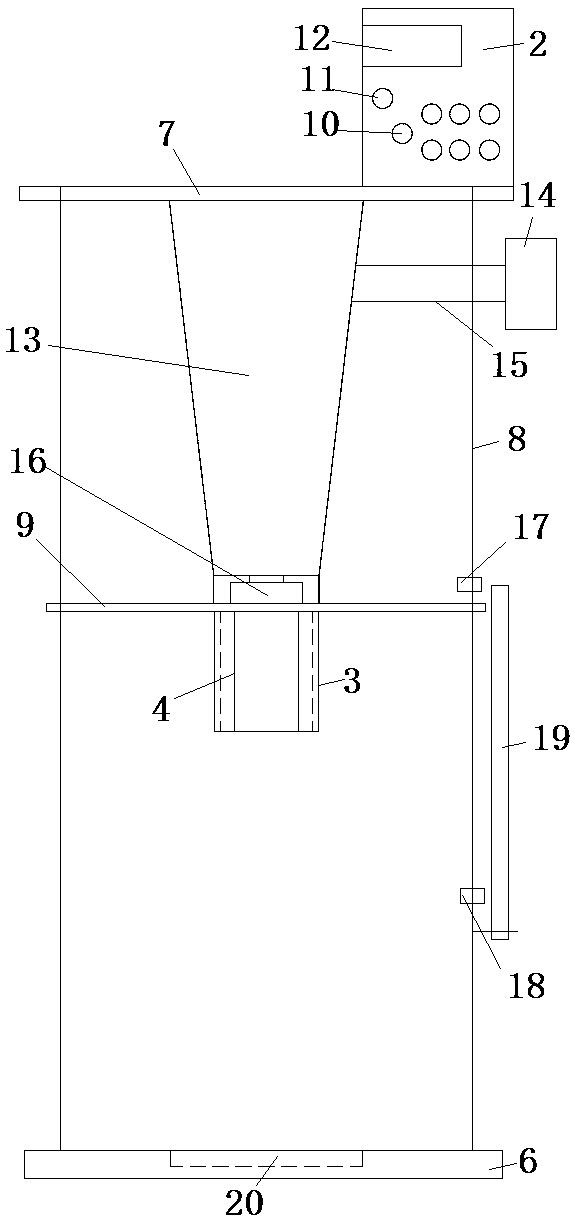

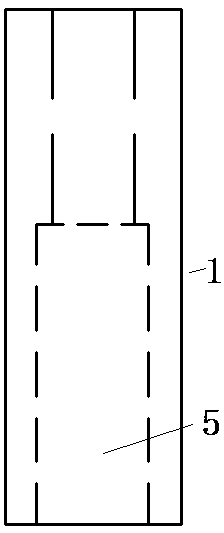

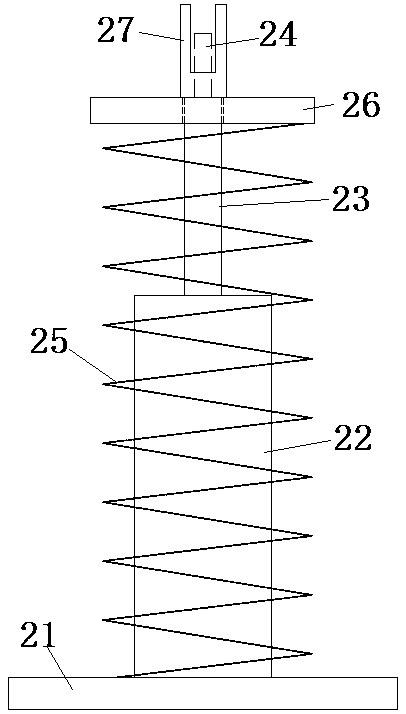

[0029] Such as Figure 1~11 As shown in the figure, an electric disassembly and assembly tool for the opening buffer includes a frame, a pull rod sleeve 1, and a power control box 2. The frame is provided with a crimping head 3 that can slide vertically on a vertical plane. , the connecting end of the crimping head and the frame is driven by an electric mechanism to realize vertical reciprocating movement, the crimping head is a cylinder with the opening direction facing downwards vertically, a gap 4 is opened on the peripheral side of the crimping head, the The central axis of the pull rod sleeve is provided with a cylindrical hole 5 for being inserted into the piston rod joint of the opening buffer. The outer diameter of the pull rod sleeve is the same as the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com