Production method of microbial inoculum

A microbial agent and production method technology, applied in the field of microbial agent production, can solve the problems of not being able to meet the needs of the market, short survival time of live bacteria, limited storage time, etc., to promote rapid reproduction, growth and reproduction, The effect of increasing fertilizer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

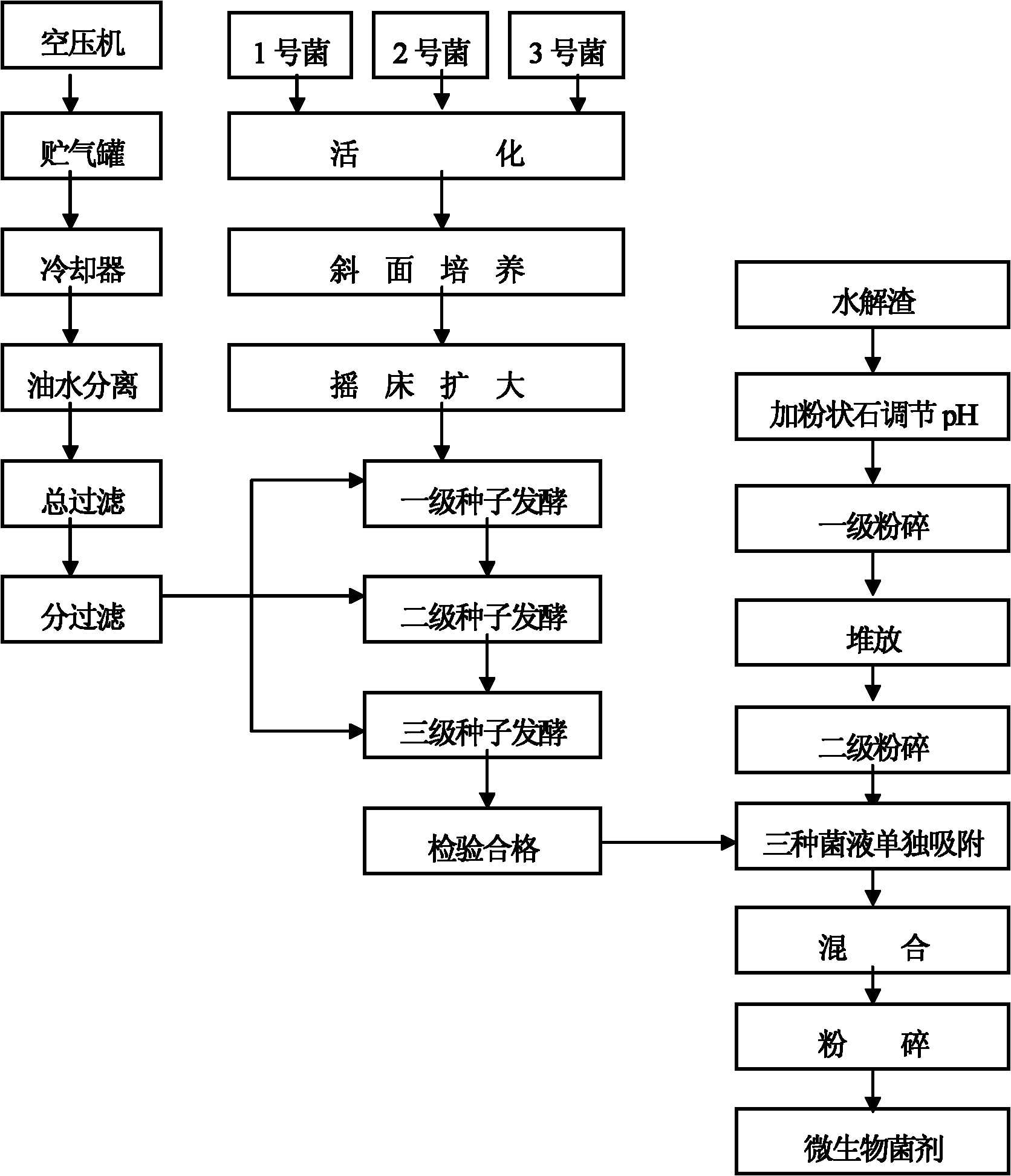

[0045] 1. Strain fermentation

[0046] The three strains of Bacillus subtilis, Bacillus megaterium and Bacillus mucilginosus krassilm were respectively subjected to slant culture, shaker expansion culture, seed tank fermentation and fermenter fermentation , the number of live bacteria in the fermentation liquid of Bacillus subtilis reached 5.3 billion / ml, the number of live bacteria in the fermentation liquid of Bacillus megaterium reached 4.6 billion / ml, and the number of live bacteria in the fermentation liquid of Bacillus peptiformis Reached 2.8 billion / ml;

[0047] 2. Sampling and processing

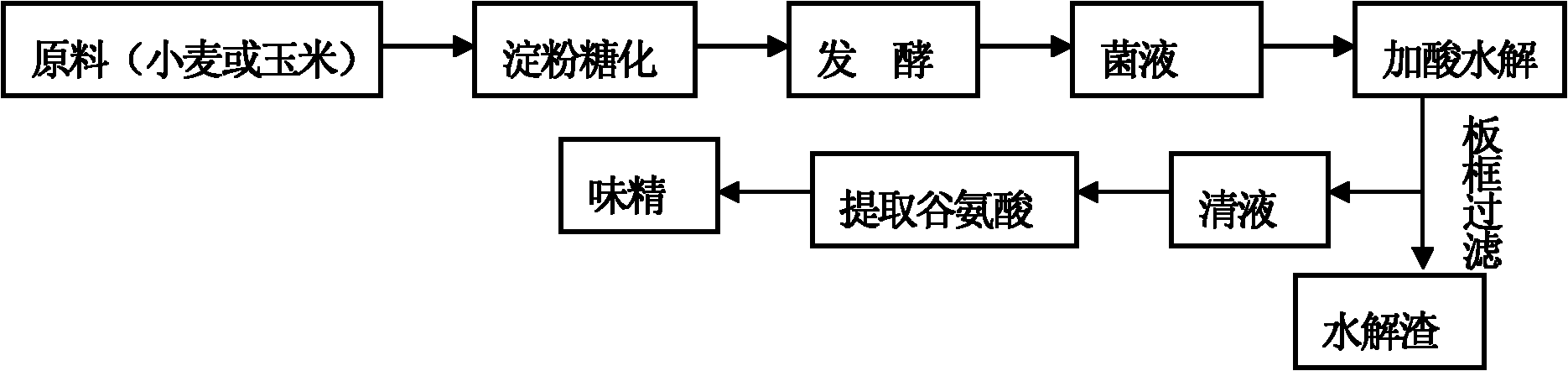

[0048] The hydrolyzed slag was obtained from Henan Lianhua Monosodium Glutamate Co., Ltd.

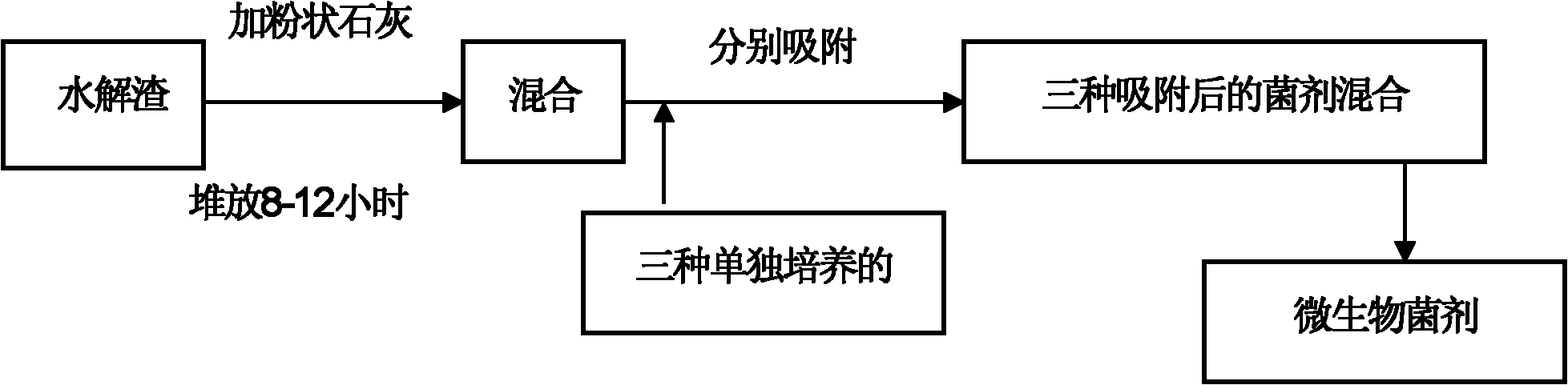

[0049] Crush the large pieces of hydrolyzed slag into powder or small particles, mix with powdered lime according to the ratio of hydrolyzed slag:lime=4:1, pulverize, pile up the finely powdered material for 12-20 hours, and then pulverize for the second time. Then sieve and pack to make th...

Embodiment 2

[0059] The three strains of Bacillus subtilis, Bacillus megaterium and Bacillus mucilginosus krassilm were respectively subjected to slant culture, shaker expansion culture, seed tank fermentation and fermenter fermentation , the number of live bacteria in the fermentation liquid of Bacillus subtilis reached 5.3 billion / ml, the number of live bacteria in the fermentation liquid of Bacillus megaterium reached 4.6 billion / ml, and the number of live bacteria in the fermentation liquid of Bacillus peptiformis Reached 2.8 billion / ml;

[0060] Crush the large pieces of hydrolyzed slag into powder or small particles, mix with powdered lime according to the ratio of hydrolyzed slag:lime=5:1, pulverize, pile up the powdered material for 12-20 hours, and then sieve and pack into bags. Its pH reaches 5.5-7.0.

[0061] Bacillus subtilis (Bacillus subtilis), Bacillus megaterium (Bacillus megaterium) and Bacillus mucilginosus krassilm (Bacillus mucilginosus krassilm) were respectively adso...

Embodiment 3

[0065] Bacillus subtilis (Bacillus subtilis) and Bacillus megaterium (Bacillus megaterium) were separately cultured on a slant, expanded culture on a shaker, fermented in a seed tank and fermented in a fermenter. The number of live bacteria in the fermentation liquid of Bacillus subtilis Reached 5.3 billion / ml, and the number of live bacteria in the fermentation liquid of Bacillus megaterium reached 4.6 billion / ml;

[0066] Crush the large pieces of hydrolyzed slag into powder or small particles, mix with powdered lime according to the ratio of hydrolyzed slag:lime=5:1, pulverize, pile up the powdered material for 12-20 hours, and then sieve and pack into bags. Its pH reaches 7.0-7.5.

[0067] Bacillus subtilis (Bacillus subtilis) and Bacillus megaterium (Bacillus megaterium) are adsorbed with the hydrolyzed slag that has been treated respectively, and the bacterium liquid of single bacterial species is according to bacterium liquid (L): hydrolyzed slag (Kg)= The ratio of 0.3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com