Process method and device for coupling acetone-butyl alcohol fermentation and separation

A butanol fermentation and coupling device technology, which is applied in the field of acetone-butanol fermentation separation and coupling, can solve the problem of high energy consumption in the separation of fermentation products, and achieve the effects of reducing energy consumption and simplifying the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

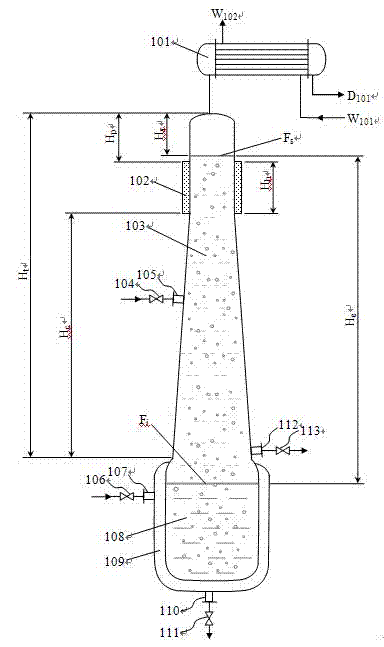

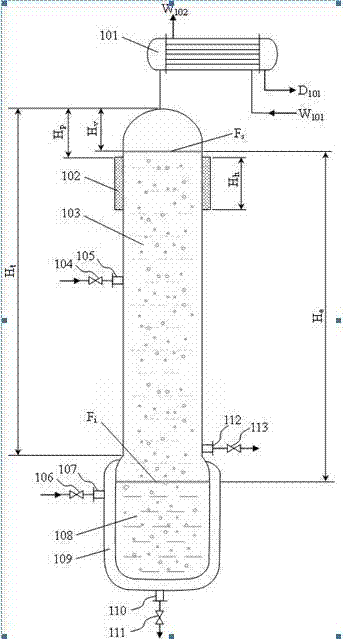

[0029] Fermentation-extraction-distillation device: the specific operation process is: first carry out acetone-butanol fermentation in a conventional fermenter, and then add the fermented liquid into the fermenter 108 through the feed port 107, or directly feed the fermentation raw materials through the feed port 107 is added into the fermenter 108 to carry out acetone-butanol fermentation; a high-boiling extractant is added to the extraction tower 103 through the feed port 105; the acetone, butanol and ethanol produced by fermentation are extracted into the extractant and migrate upward; Turn on the cold source of the condenser 101, turn on the heater 102 to heat the extractant in the upper part of the extraction tower, the acetone, butanol and ethanol dissolved in the extractant are continuously vaporized, and collected after being condensed by the condenser 101. After fermentation-extraction-distillation, the fermented liquid can be discharged from the discharge port 110; wh...

Embodiment 2

[0035] Fermentation-extraction-distillation unit: attached figure 1 In the shown device, the volume of the fermenter 108 is 0.8 liters, and the diameter of the inner cylinder is 0.08 m; the height of the extraction tower 103 is H t is 0.4 m, and the inner diameter of the tower is 0.08 m; the heater 102 is an electric heating jacket, located on the outer wall of the upper part of the extraction tower 103, and the height of the jacket is H h is 0.05 m, its power is 0.8 kW, and the distance H between its upper edge and the top of the extraction tower p is 0.05 m.

[0036] Fermentation-extraction-distillation process: using the device described in this example, insert the activated bacterial solution into 7% corn mash culture medium with a 5% inoculum size, the total volume is 0.8 liters, and add it through the feed port 107 In the fermentor 108, then add oleic acid in the extraction tower 103 through the feed port 105 as the extractant until the liquid level of the extractant i...

Embodiment 3

[0039] Fermentation-extraction-distillation unit: attached figure 1 In the shown device, the fermentor 108 has a volume of 5 liters, and the diameter of the inner cylinder is 0.15 m; the height of the extraction tower 103 is H t is 1.5 m, and the inner diameter of the tower is 0.15 m; the heater 102 is an electric heating jacket, located on the outer wall of the upper part of the extraction tower 103, and the height of the jacket is H h is 0.25 m, its power is 3 kW, and the distance H between its upper edge and the top of the extraction tower p is 0.3 m.

[0040] Fermentation-extraction-distillation process: insert the activated bacterial liquid into 7% corn mash culture medium according to the inoculation amount of 5%, the total volume is 50 liters, and first culture it at 37°C for 72 hours; adopt this embodiment In the device, 5 liters of fermented liquid are added to the fermenter 108 through the feed port 107, and then through the feed port 105, isostearic acid is added ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com