Manufacturing method for environment-friendly antiseptic polyvinyl chloride light-type conveyer belt and antiseptic coating material

A light conveyor belt, polyvinyl chloride technology, applied in conveyors, antifouling/underwater coatings, coatings, etc., can solve the problem of affecting the appearance and physical properties of polyvinyl chloride conveyor belts, easily producing microorganisms, and threatening human health and other problems, to achieve high chemical stability and thermal stability, less addition, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

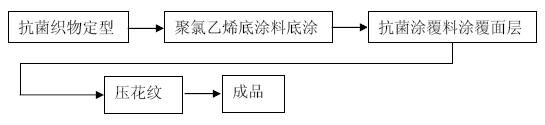

[0034] see figure 1 Shown in the process flow chart of the environment-friendly antibacterial polyvinyl chloride light conveyor belt of the present invention, the manufacturing method of the environment-friendly antibacterial polyvinyl chloride light conveyor belt of the present invention: adopt coating process, utilize far-infrared heating mode to produce, its The production process is as follows: antibacterial fabric shaping, primer coating, surface layer coating with antibacterial coating material, embossing pattern, and finished product.

[0035] The specific steps are:

[0036] The first step: drying the antibacterial fabric in a far-infrared heating oven, and setting it by tentering;

[0037] The second step: on the shaped antibacterial fabric, use polyvinyl chloride paste resin as the primer for primer coating, and heat and plasticize it in a far-infrared heating oven;

[0038] The third step: coating the antibacterial PVC coating material on the primer layer, and hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com