Method for recycling thermoplastic polypropylene plastic parts of scraped automobile

A technology for polypropylene plastics and scrapped cars, which is applied in plastic recycling and recycling technology, and can solve the problems of low added value of remanufacturing, low feasibility of mixed recycling and remanufacturing methods, narrow industrial application range, etc., and achieve good comprehensive performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

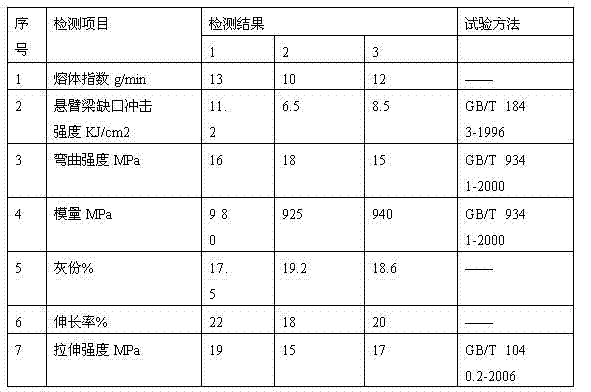

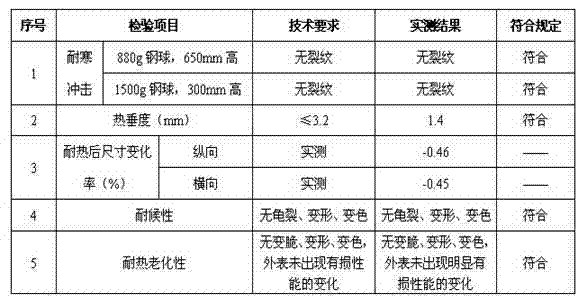

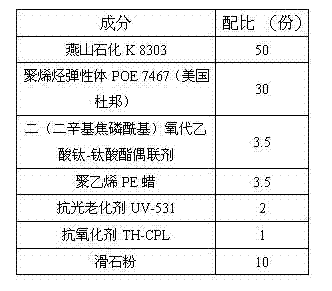

Embodiment 1

[0048] Manually disassemble scrapped cars, remove bumpers, instrument panels, door trim panels, lights and other interior and exterior plastic and structural parts, and classify thermoplastic components into ABS, PP, PC, PVC materials, etc. Remove the metal links (such as screws, etc.) as far as possible, and control the impurity purity of the sorted PP material parts below 1%; use two-stage crushing, use a large crusher for coarse crushing, use a 6mm screen, and crush the particle size to 6mm or less, in order to improve the crushing efficiency, use a shearing crusher for fine crushing, use a 1mm screen, and finally crush to less than 1mm to obtain a thermoplastic polypropylene plastic powder mixture less than 1mm, and then separate the metal debris by ferromagnetic separation , and then carry out high-voltage electrostatic sorting, high-voltage electrostatic sorting adopts double-roller corona discharge high-voltage electrostatic sorting machine, corona electrode adopts wire ...

Embodiment 2

[0050] Manually disassemble scrapped cars, remove bumpers, instrument panels, door trim panels, lights and other interior and exterior plastic and structural parts, and classify thermoplastic components into ABS, PP, PC, PVC materials, etc. Remove the metal links (such as screws, etc.) as far as possible, and control the impurity purity of the sorted PP material parts below 1%; adopt two-stage crushing, use a large crusher for coarse crushing, use a 12mm screen, and crush the particle size to 12mm, in order to improve the crushing efficiency, use a shearing crusher for fine crushing, use a 1mm screen, and finally crush to less than 1mm to obtain a thermoplastic polypropylene plastic powder mixture less than 1mm, and then perform ferromagnetic separation to separate metal debris, Then carry out high-voltage electrostatic sorting, high-voltage electrostatic sorting adopts double-roller corona discharge high-voltage electrostatic sorting machine, corona electrode adopts wire elect...

Embodiment 3

[0052] Disassemble scrapped cars, remove bumpers, instrument panels, door trim panels, lights and other interior and exterior plastic and structural parts, and classify thermoplastic components according to ABS, PP, PC, PVC materials, etc. Remove metal links as much as possible (such as screws, etc.), and control the impurity purity of the sorted PP material parts below 1%; adopt two-stage crushing, use a large crusher for coarse crushing, and use an 8mm screen to crush the particle size to 6~ 8mm or less, in order to improve the crushing efficiency, use a shearing crusher for fine crushing, use a 2mm screen, and finally crush to less than 2mm, screen out the thermoplastic polypropylene plastic powder mixture less than 1mm, and then separate the metal fragments by ferromagnetic separation Chips, and then carry out high-voltage electrostatic sorting, high-voltage electrostatic sorting adopts a double-roller corona discharge high-voltage electrostatic sorting machine, the corona ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com