Heavy-calibre spiral corrugated pipe machine

A large-diameter, spiral technology, which is applied in the mechanical field of processing large-diameter spiral corrugated pipes, can solve the problems of weak strength, high cost, and many steps at the welding point, achieve a high degree of automation, improve processing efficiency, and overcome the problems of low strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

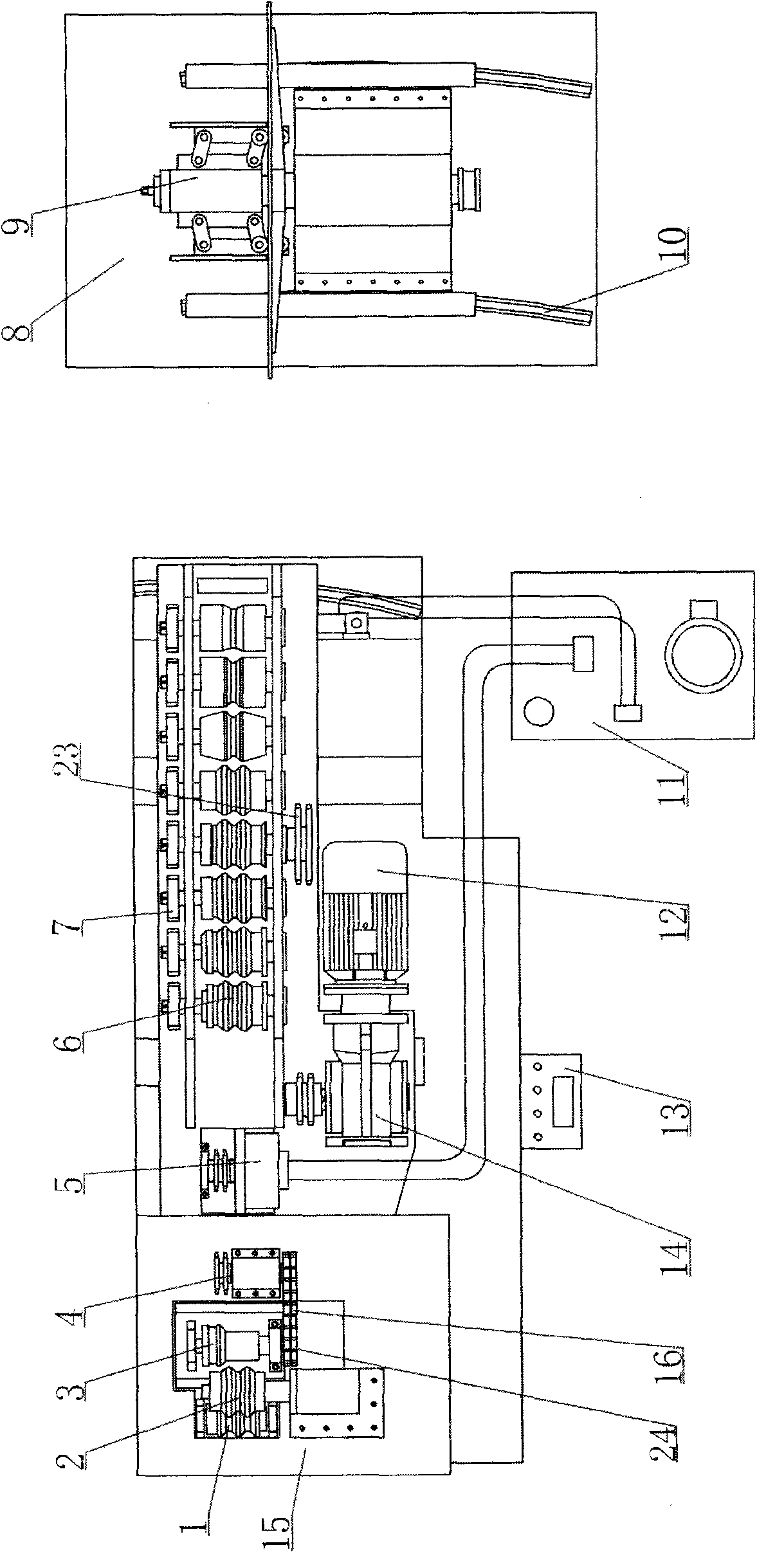

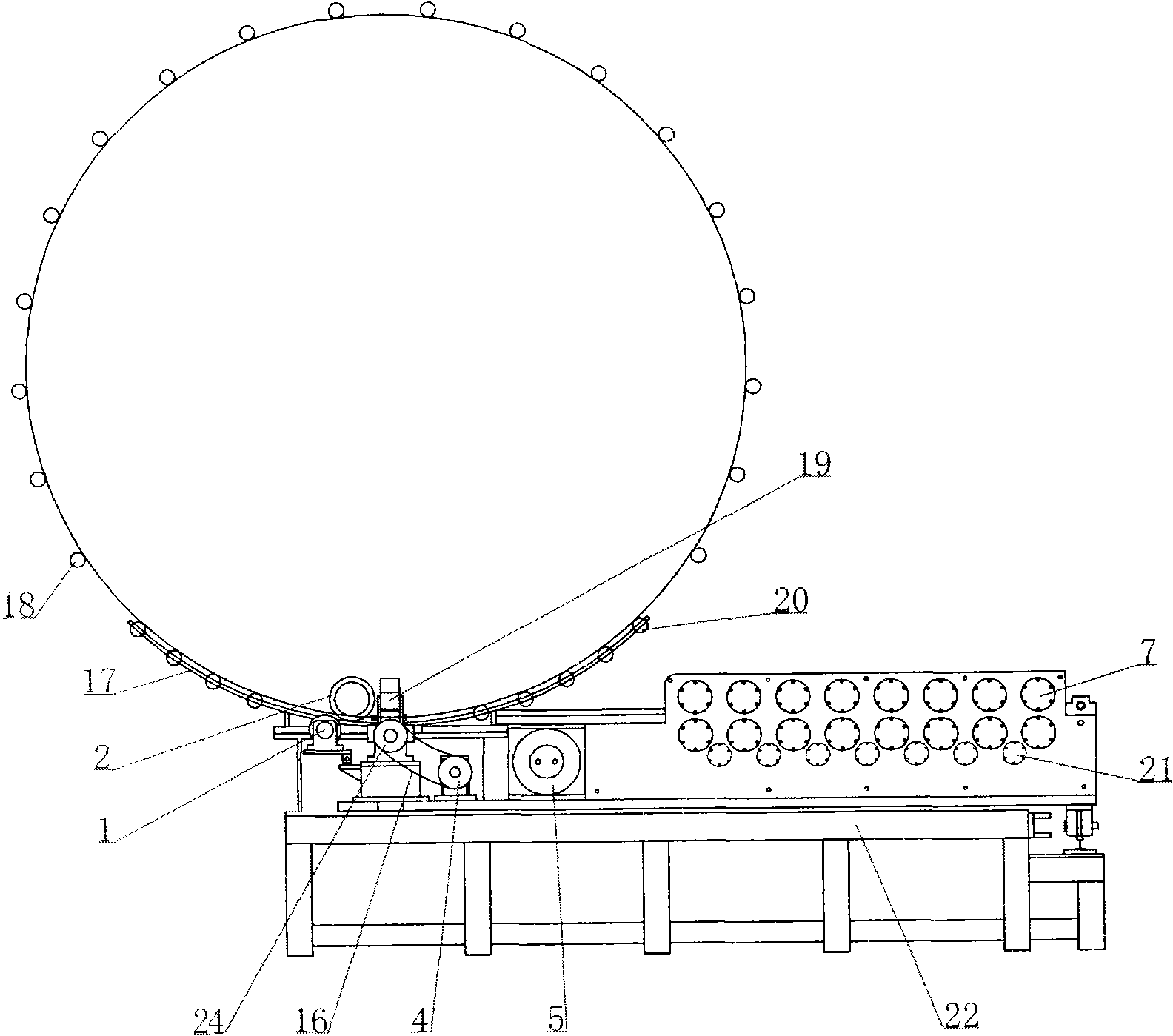

[0012] see figure 1 , The large-diameter spiral bellows machine is composed of a feeding unit, a rolling unit, a bite rolling unit and a console 13 that controls the operation of the machine. The console 13 realizes the control of the machine through PLC and frequency converter.

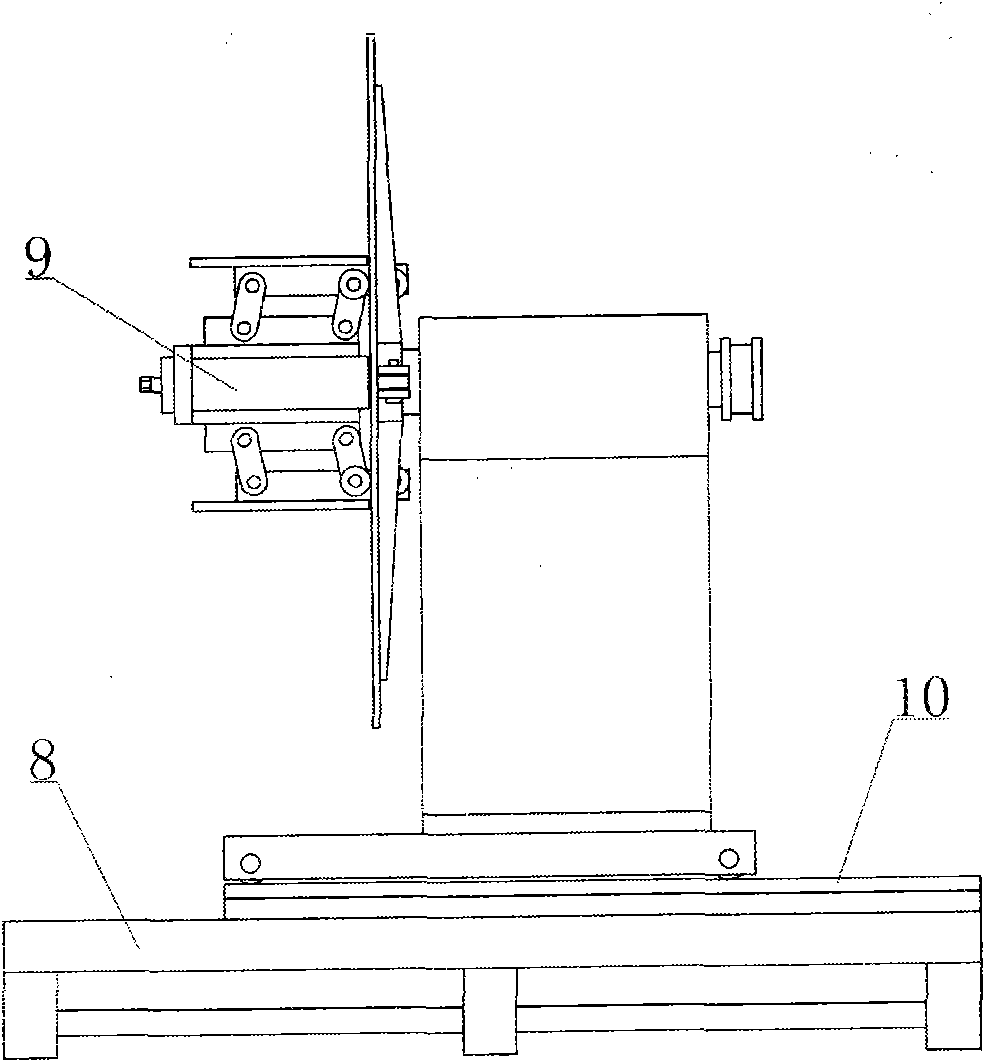

[0013] see figure 1 , 2 , the feeding unit is provided with an uncoiler 9, and the bottom end of the frame of the uncoiler 9 is fixed on the arc track 10 of the base 8, which plays a supporting role for the material belt, and the uncoiler 9 can slide on the arc track 10, to adjust the angle. Uncoiler 9 can be selected with a load of 3 tons and a specification of 2.2×1.5×2.4m.

[0014] see figure 1 , 3 , 4, the profiling unit is provided with a profiling roll group driven by a motor 12, and the profiling roll group is composed of several profiling rolls 6 correspondingly distributed in two rows up and down, and the roller surfaces of the profiling rolls 6 corresponding up and down It is equipped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com