Method and system for combined treatment of boiler smoke and alkaline waste water and waste heat utilization

A technology for boiler flue gas and combined treatment, which is applied in separation methods, chemical instruments and methods, and the use of liquid separation agents, can solve the problems of high operating costs, low operating costs, and low desulfurization efficiency. High efficiency and the effect of reducing enterprise operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

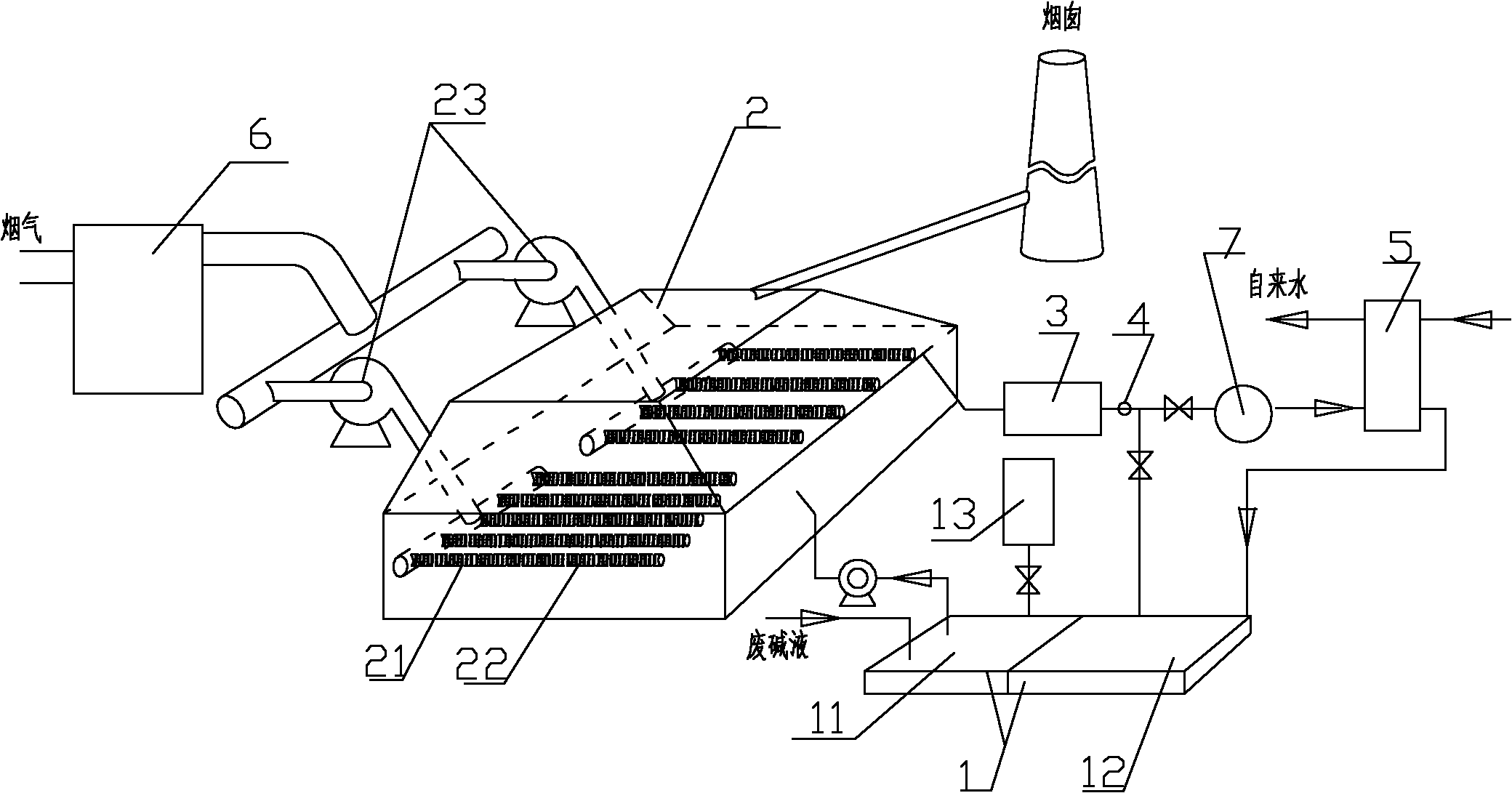

[0024] from figure 1 It can be seen from the shown technological process that the method of the present invention is to send the alkaline waste water to the integrated circulation pool 1 after primary filtration, and to adjust the water quality and quantity; 2 Intense contact with the flue gas for desulfurization and dust removal; the waste water from the integrated desulfurization and dust removal device 2 is sent to the separation sedimentation tank 3, and after removing the flue gas dust in it, the temperature is detected by the temperature sensor 4; if the waste water from the sedimentation tank 3 When the temperature of the wastewater reaches the set value, it is filtered and then sent to the water-water heat exchanger 5 for heat exchange with tap water; Sent to waste liquid pool 12.

[0025] The comprehensive circulation tank 1 wherein is divided into two parts, the front part is the lye tank 11, and the rear part is the waste liquid tank 12, and the middle part is sepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com