Method for preparing third-level strain of pleurotus eryngii

A technology for tertiary strains and king oyster mushrooms is applied in the fields of botanical equipment and methods, fertilizer mixtures, horticulture, etc., which can solve the problems of strict operating conditions, complicated equipment, and difficult technical mastery, and achieves simple operation, The effect of uniform distribution and simplified strain preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

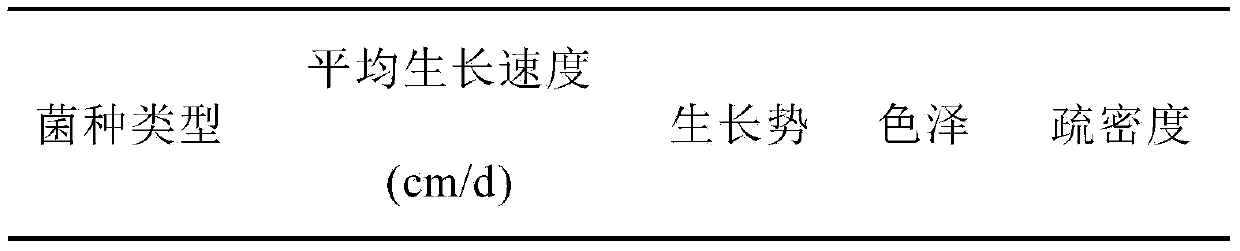

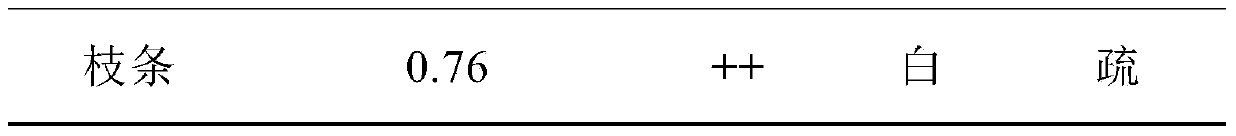

[0050] A method for preparing the three-stage strain of Pleurotus eryngii, a specific scheme created by the present invention

[0051] The primary and secondary strains of Pleurotus eryngii adopt the traditional seed production process.

[0052] The third-level strains are made from branches, and the production process is as follows:

[0053] (1) Preparation of shoot medium

[0054] Branches: poplar branches, cut into 1cm 2 ×15cm size;

[0055] Bridging materials: 120g of broad-leaved sawdust, 24g of bran, and 2.8g of calcium carbonate.

[0056] After the branches are soaked in lime water for 24 hours, rinse them several times with clear water until there is no residual lime water on the surface, stir them evenly with 24g of bran, and pack them into 750ml glass bottles, with 40 branches in each bottle, compacted, without gap. Add water and stir the other ingredients in the bridging material formula evenly, fill up the empty part of the bottle, stuff it with a cotton plug,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com