End face tooth engaged and separated structure for speed reducer of mowing machine

A technology of end-face gear meshing and separation structure, which is applied in the direction of harvesters, agricultural machinery and implements, etc. It can solve the problems of slipping, unable to go uphill, unable to work effectively, and affect the service life, so as to improve the strength and speed of engagement or separation , climbing speed and mowing efficiency are improved, and the service life is extended

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

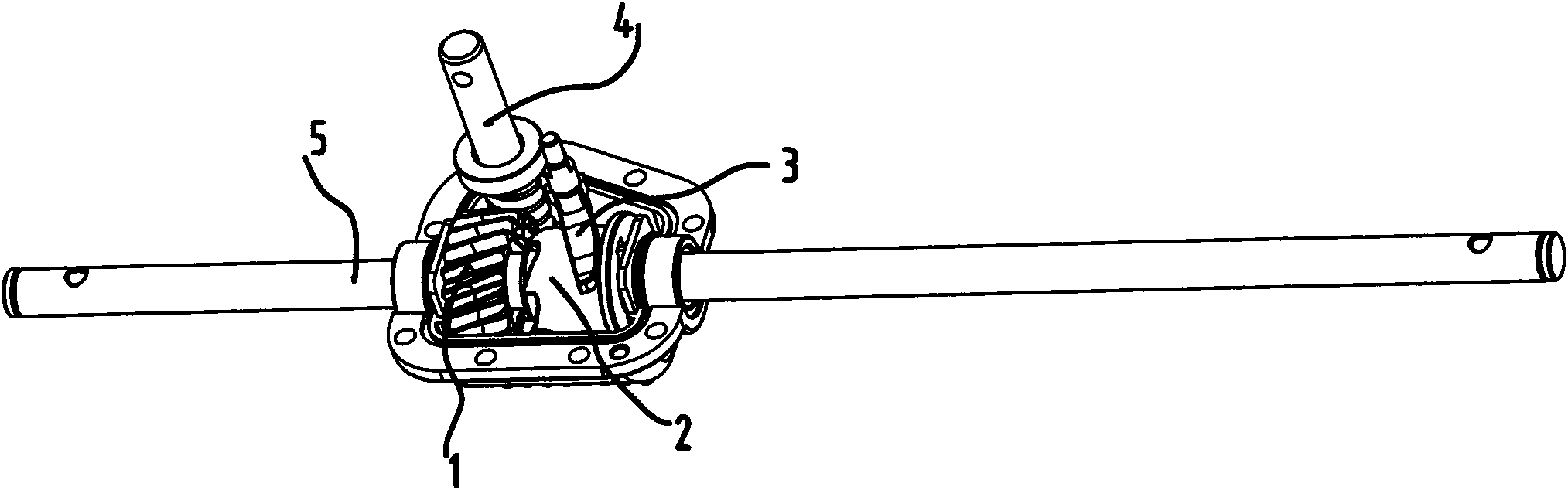

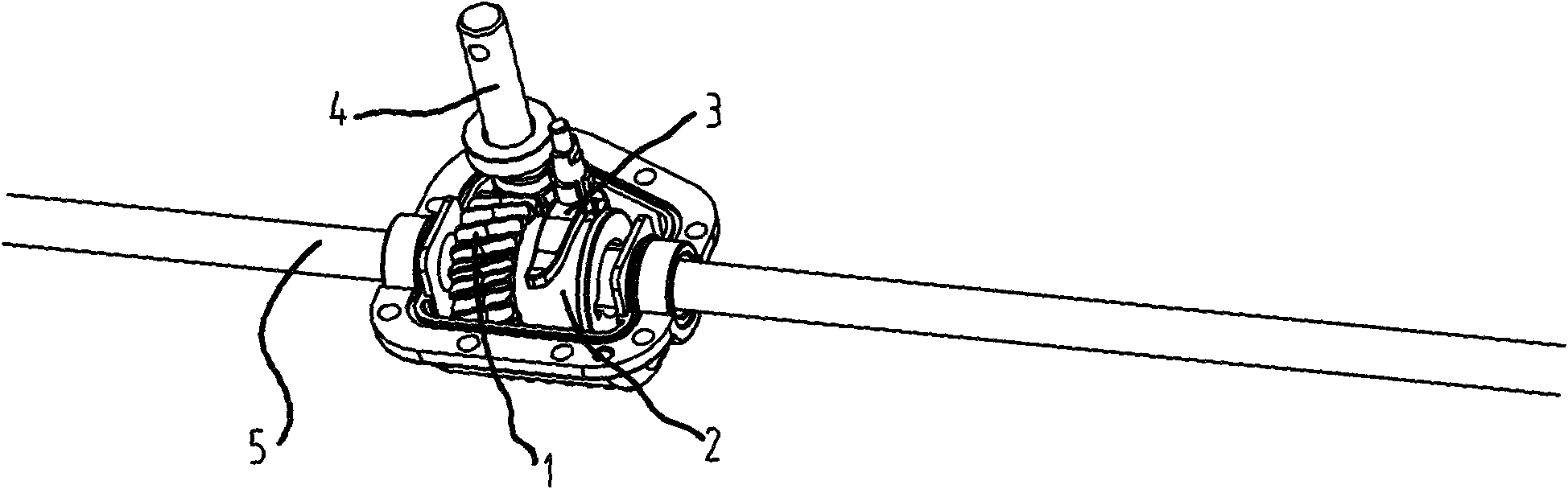

[0012] Figure 1a with Figure 2a Shown is the three-dimensional structure diagram of the present invention after the reduction box cover is removed, the lower end of the power input shaft is a worm 4 with helical teeth, the worm gear 1 and the worm 4 are meshed with each other by the helical teeth, and the power output shaft 5 is arranged in the central cavity of the worm gear 1 And pass through the shaft sliding sleeve 2, the shift fork 3 slides and is stuck on the shaft sliding sleeve 2 outer wall.

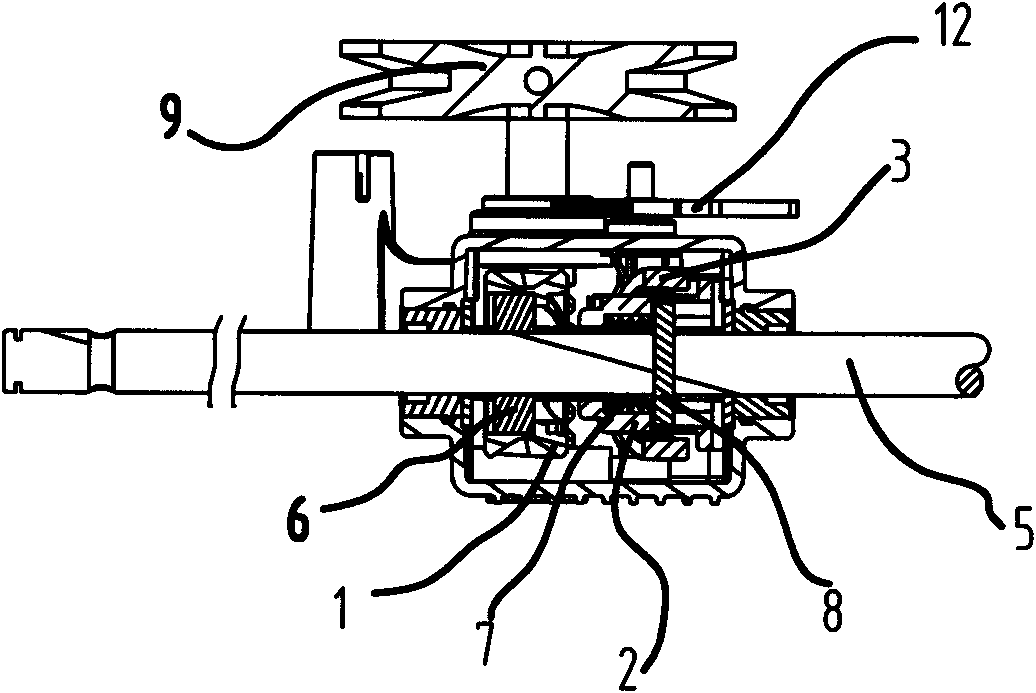

[0013] Such as Figure 1b , Figure 2b with Figure 3a As shown, the pulley 9 is fixedly connected to the end of the power input shaft, the power output shaft 5 passes through the inner cavity of the worm wheel 1 and is rotatably fixed by the bearing 6, and the power output shaft 5 enters the inner cavity of the shaft sliding sleeve 2, and is arranged on the shaft The positioning pin 8 on the inner wall of the sliding sleeve 2 passes through the power output shaft 5 vertical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com