Device and method for secondary cooling in a continuous casting system

A cooling device and secondary cooling technology, which is applied in the field of secondary cooling devices, can solve the problems of nozzle position matching and inability to show nozzle matching, etc., and achieve efficient cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

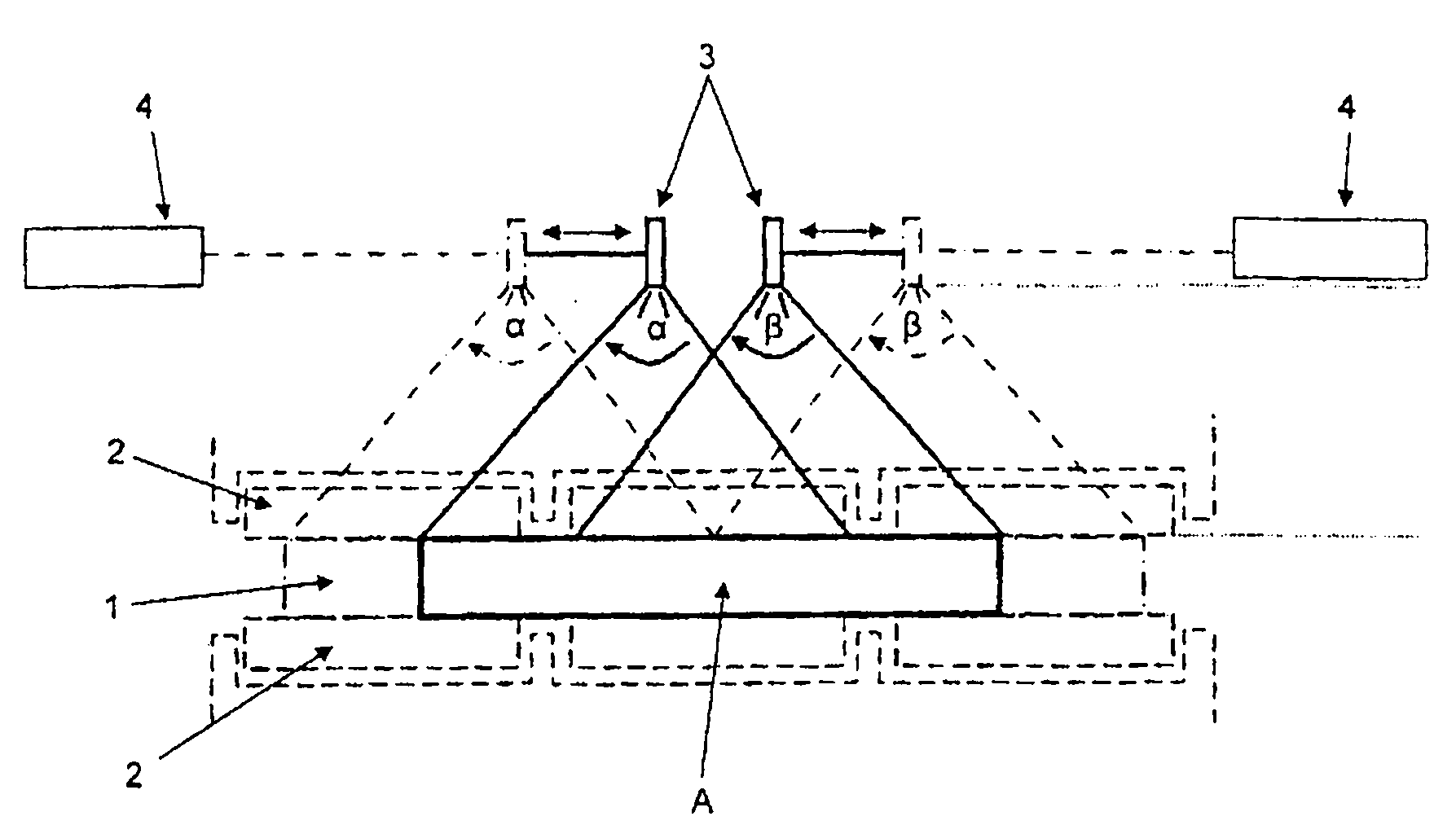

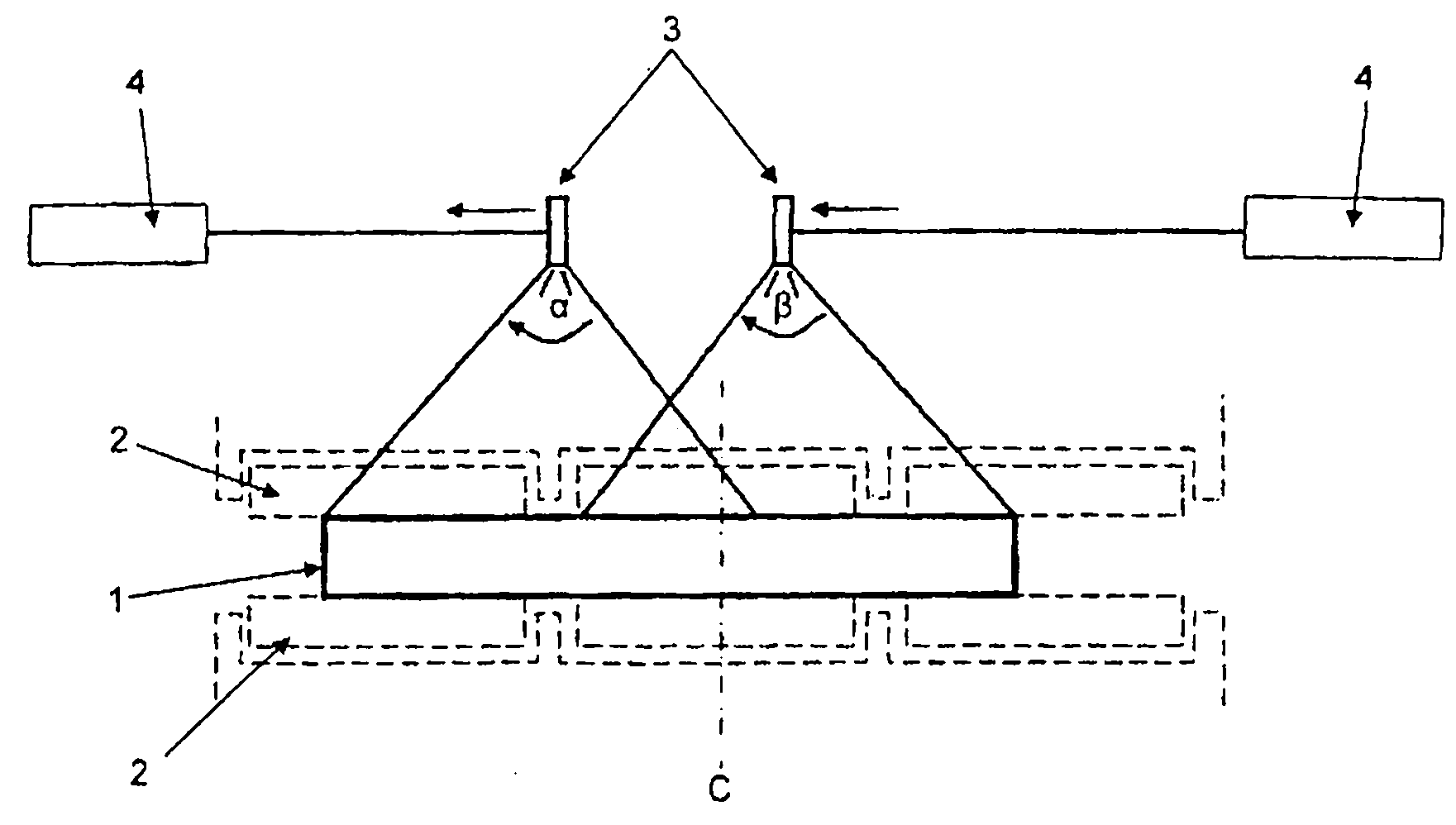

[0044] exist Figure 1a Among them, the continuous casting strand 1 is located between the rollers 2 of the continuous casting strand guiding part. Figure 1a The nozzles 3 in each are linearly moved by a moving and positioning device 4 . The direction of movement or axis of movement is indicated by a double arrow in the figure. Nozzles 3 spray water onto the strand 1 . In this case, not the entire width of the strand 1 but only the region A of the strand 1 is sprayed. The nozzles 3 have spray angles of α and β. The nozzle 3 drawn in dotted lines, including its spray area drawn in dotted lines with angles α and β, shows a state in which the entire width of the strand 1 is to be provided with water spray. The displacement and positioning device 4 can in particular be formed in the form of at least one linear guide on which the nozzle 3 is moved by means of a displacement drive.

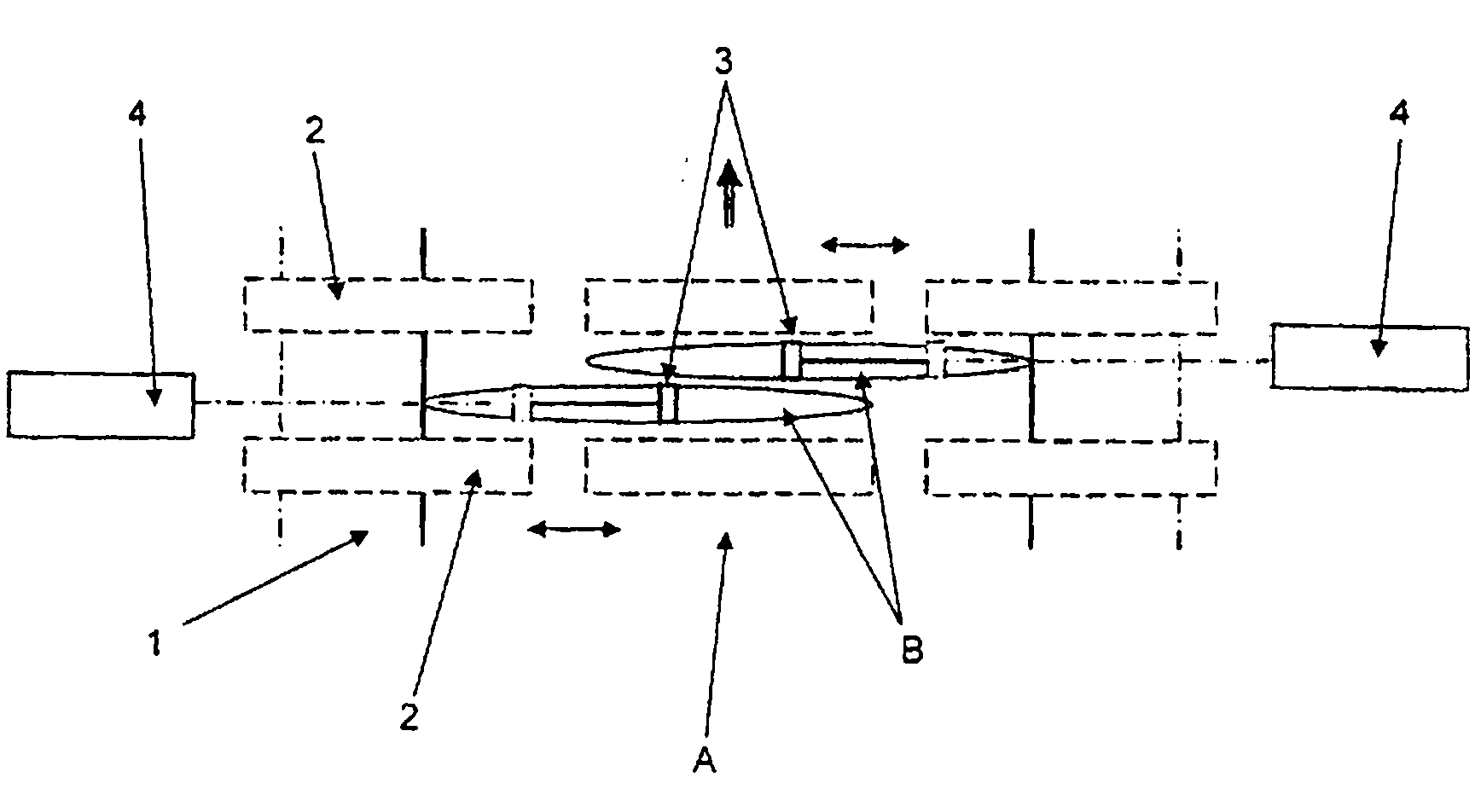

[0045] Figure 1b shows the same Figure 1a The same components, however shown in top view. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com